Meta Description: Learn all about stack-up analysis, how to do it and the best techniques of tolerance stack up methods, tolerance stacking techniques and methods used in real life manufacturing and manufacturing quality control and precision engineering.

The world of precision manufacturing and global logistics is a place where stack-up analysis plays an instrumental role in ensuring the quality of the whole supply chain remains intact. International shipping and the process of customs clearance are the areas where we have observed how the use of tolerance has positively impacted our business at Shenzhen

What is Stack-Up Analysis in Manufacturing

Tolerance stacking, as such is also called stack-up methodology, is an influential engineering approach towards assessing the combined impact of individual tolerances and tolerance stack analysis on manufactured parts. This is a systematic process through which when various parts are put together their resultant dimensional deviations do fall within acceptable levels in order to build acceptable functionality.

The underlying concept is that of examination of individual geometric tolerances of inter-related characteristics with a view to effecting total assembly tolerances. It is a necessary step which is used to avoid a situation when separate parts fulfill their specifications, but when assembled together they fall short of quality requirements because of tolerances added together.

The Engineering Foundation of Tolerance Stacking

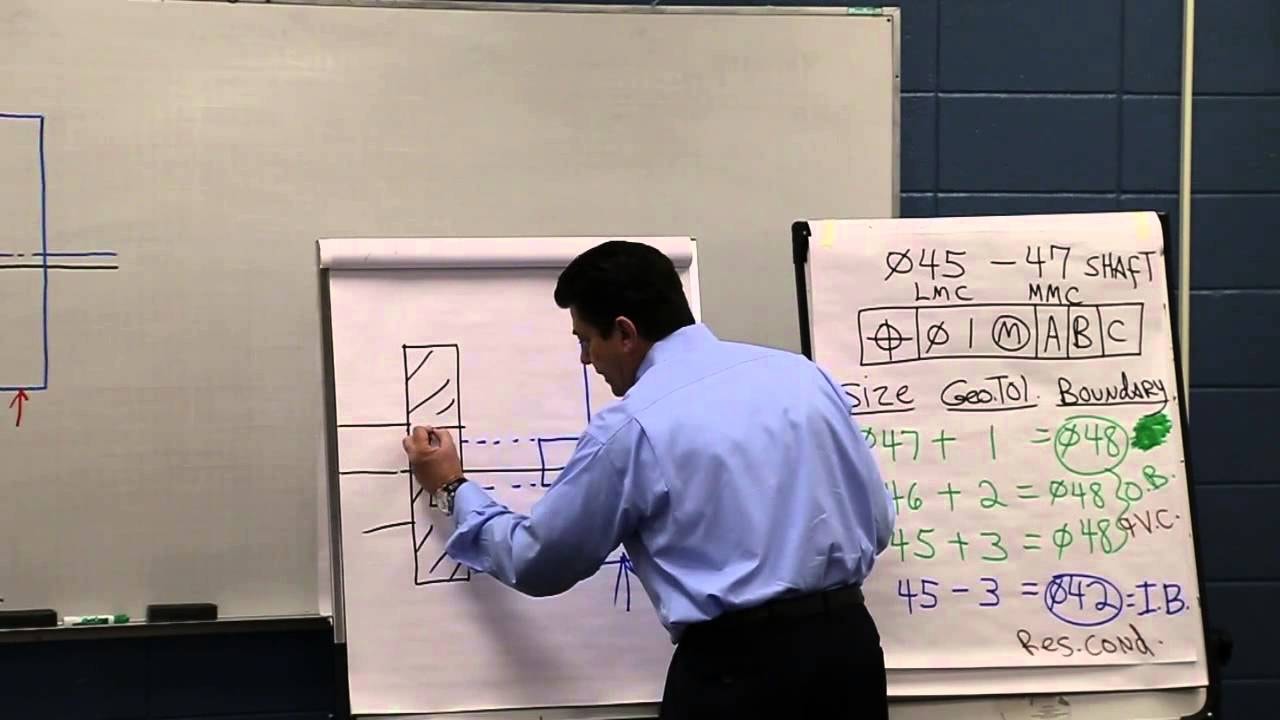

Tolerance stacking is based on the Geometric Dimensioning and Tolerancing (GD&T) concepts, and is one of the means to connect the ideal design with manufacturing practice. This technique is applied by the engineers in order to determine the assembly behavior in advance of the manufacturing process, thus the possibility of making expensive mistakes and remakes is greatly mitigated.

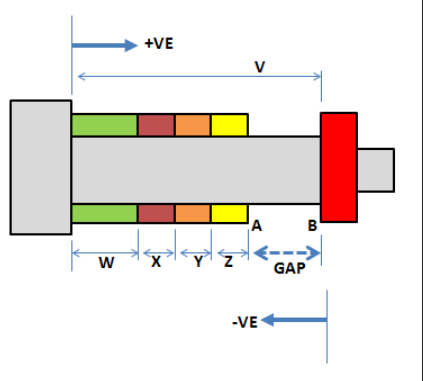

The underlying mathematical science relates to the situation that considers how individual dimensional variations travel along an assembly chain. The assembly tolerance arises out of the tolerance of each component, meaning that there is a cumulative effect that has to be controlled well so that the functional requirements could be met.

Critical Importance in Modern Manufacturing

The world of manufacturing today is very competitive, and the practice of tolerance stackup analysis has a variety of essential applications outside the scope of quality control. It allows manufacturers to streamline manufacturing processes and eliminate wastage and achieve consistency in vast productions concurrently but also catering to the needs of global supply chains.

The approach is especially useful when working on high precision components that will be exported; the customs clearance and certification of the product as per quality standards require the stringent parameter of precision and assembly variation to be met to the dot.

Worst Case Tolerance Analysis Method

The worst-case method is the most conservative type of stack-up analysis where it would assume that all of the component tolerances will all reach their extreme limits at the same time. Although the scenario is not statistically likely, this gives the greatest assurance that there is functionality in assembly.

The method can add those individual tolerance values arithmetically to come up with the biggest tolerable stack. The method ensures 100 percent of the assemblies will work, and therefore it is best applied in high-stake industries such as aerospace, medical devices, etc. where failure tolerance is not an option.

The worst-case Analysis mathematical expression is obtained by adding both side tolerances: Total Variation = Sum (+(+Ti)) where Ti are one-sided tolerances of individual components. Although it makes the solution fully reliable, this can lead to the unnecessary tight tolerances, which make the manufacturing process costly and complex.

Statistical Tolerance Analysis and RSS Method

Analysis with statistical tolerance is more realistic and economical since probability distribution of variation in dimensions is taken into account. This is the most used statistical tool, Root Sum Squared (RSS), which proposes that manufacturing variations are normally distributed.

This is because this methodology acknowledges the fact that in the real manufacturing world, not every component will be at its maximum tolerance limit in the same situation. Rather changes take place in predictable statistical patterns that enable them to allocate the tolerances in a more optimizing way and at the same time achieve the acceptable levels of quality.

The RSS formula to compute assembly tolerance computes the assembly tolerance in the following ways; Tasm = 2(Sigma(Ti 2)) with Ti some component tolerances. The method usually leads to much tighter assembly tolerances than worst-case analysis, so manufacturing can be economical, yet retain an acceptable level of quality control.

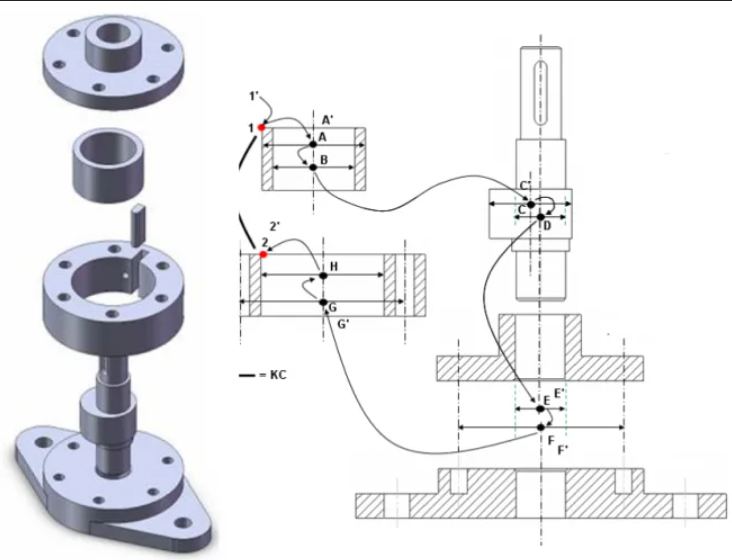

Dimensional Chain Analysis Fundamentals

Dimensional chain analysis is the core of the proper stack-up analysis including all the identification and evaluation of the tolerance paths that combine into the critical assembly dimensions. Such an undertaking needs more attention to the interaction and working of the component features with the assembly performance at large.

The engineers need to be able to find the whole tolerance chains and not just the direct or indirect dimensions one. Each chain is a route that dimensional variations may travel down to possibly compromise quality of final assembly and functionality.

The solution includes mapping geometric relations, developing datum reference points as well as determining cumulative effect with numerous components. Such systematic method helps all the possible sources of variation to be taken into consideration and controlled well.

Manufacturing Process Considerations

Effective stack-up analysis has to consider the real-world manufacturing limitations and abilities. Diversity among manufacturing processes leads to a variation in precision and consistency, which has a direct reflection on the individual process and tolerance accomplishment and stack-up.

Studies of process capability can be used as a source of input data into stack-up analysis to determine realistic tolerances ranges using actual manufacturing performance. The information also helps engineers to match design requirements and the production capacities to minimize the possibility of facing challenges during production and compromising on quality.

Manufacturing sequence, tool accuracy, and process stability should be considered so that the stack-up analysis would render to the manufacturing reality. Theoretical analysis and practical manufacturing capabilities are of importance to this implementation.

Quality Control Integration Strategies

The analysis of tolerance stackup should be incorporated with other thorough quality control systems as a way of effective execution. Such integration is done by ensuring that there are protocols on measurements, inspection as well as correction actions that are in consonance with analytical expectations.

The SPC methods present useful feedback in supporting the assumptions to be vindicated in stack-up analysis and discover the variations in the processes available that may influence the quality of assembly. Constant tracking and modification put a lot of manufacturing processes in order with regards to analytical expectation.

The implementation of stack-up analysis is aided by documentation and traceability systems where historical data can be referred to in the process of improvement and quick detection of quality problems once they arise.

Advanced Software Tools and Technologies

Recent Computer-Aided design (CAD) products and Computer-Aided engineering (CAE) software suites have advanced tolerance analysis tools that facilitate simple implementation of stack-up analysis. These tools simplify the computation of complicated calculative problems, visualization chain of tolerance, and quick design refinement.

Advanced Monte Carlo simulation techniques can be utilized to take advantage of the elaborate probabilities distributions of the assembly tolerances and conduct a detailed statistical analysis. Such functionalities enable engineers to test the robustness of their design in addition to allocating tolerances to meet a particular quality and cost requirement.

Systems that are integrated with manufacturing execution systems (MES) and quality management systems (QMS) allow monitoring and adjusting the stack-up performance in real-time, which is beneficial to continuous improvement and providing consistent quality delivery.

Industry-Specific Applications

The fields vary due to customized methods of stack-up analysis on the basis of the needs of the particular industry performance, regulations and client needs. The automotive use cases focus on durability and safety whereas electronics are on miniaturization and precision.

Aerospace and defense: Aerospace, and defense, application involve the utmost reliability, and in many cases, a worst-case analysis procedure and validation tests may be needed. The manufacturing process of medical equipment should have been regulated with high requirement, and regulated in costs.

Statistical techniques are useful in consumer products where there is a trade off between quality need and the economics of manufacture so that competitive prices can be achieved with an acceptable level of performance.

Cost Optimization Through Tolerance Management

Good stack-up analysis leads to a lot of cost optimization, through the tolerance stack up calculations and identification of areas where the tolerances of individual components may be relaxed, without degrading the required performance of the assembled product. This streamlines manufacture and reduces the production complexity and consequent production costs safety factor.

The analysis is useful to single out important part tolerances and tolerance relationships that yield assembly performance and so, engineers can concentrate pitch tightening where results matter most. It is quite important that tolerances not critical can sometimes be loosened critical features, which makes manufacturing easier and cheaper performance limits.

Value engineering techniques involves use of stack-up to assess trade-offs between component cost and assembly throughput, so that sound decisions can be made to optimize product-wide economics production processes.

Common Pitfalls and Error Prevention

One learnt that inexperienced engineers tend to make fatal mistakes in the stack activity analysis which may result into manufacturing and quality issues. The unnecessary tight tolerances invaribly add costs to the designs without according any benefits at all as they can over constrain designs.

Not putting manufacturing process capabilities into account may lead to unrealistic tolerances whose requirements cannot be met during the manufacturing process on a consistent basis mechanical engineering. When this intent and its manufacturing reality do not match, problems with quality and additional costs arise.

Poor analysis of completeness of tolerance chains can fail to take into consideration important dimensional interrelationships and adding tolerances which will cause unforeseen assembly issues when manufacturing. These oversights can be avoided by systematic analysis procedures.

Best Practices for Implementation Success

To implement a successful stack-up analysis it is crucial that the best practices set forth that have been sufficiently demonstrated by multiple industries and applications. Well documented assumptions and methods of analysis lead to consistent application and ease the design review.

The design, manufacturing and quality teams perform cross-functional collaboration in order to have all the perspectives included when developing analysis. Through this cooperation, the accuracy of analysis is enhanced and the implementation process is made successful.

By cross-checking the results of the analysis with the actual production data on a regular basis, one may improve analytical procedures and assumptions constantly mechanical tolerance stackup. This is the feedback loop to the stack-up analysis to keep it in line with the real world performance positive direction.

Digital Transformation and Industry 4.0

Digital manufacturing is turning the stack-up analysis into an area redefining the field of advanced data analysis, machine learning, and artificial intelligence. These technologies allow optimizing analysis in real time and predict quality management assembly measurement.

Internet of Things (IoT) sensors will allow constant monitoring of the manufacturing process and allow real-time modification of the specified stack-up parameters according to the current performance assembly standard deviation. The ability favors adaptive manufacturing approaches allowing optimization of quality and efficiency at the same time.

Artificial intelligence algorithms can fulfill the role of detecting patterns in stack-up performance data that human analysts fail to recognize which allows going proactive in terms of managing quality and ensuring that analytical methods are continuously improved allowable tolerance range.

Future Trends and Developments

Next, the advance is expected in stack-up analysis incorporation with novel manufacturing processes such as additive manufacturing, clever materials, and self-automated assembly systems worst case tolerance stack. Newer methodologies and analytical approaches will be necessary when it comes to these developments.

AI and machine learning will become more effective to optimize stack-up analysis since knowledge in this field will make adjustments to changing manufacturing conditions and normal distribution of customer needs in real-time.

Connection with digital twins will allow stack-up design verification to be conducted virtually without material production, thus developing the product faster and more successfully producing quality the first time.

Regulatory Compliance and Standards

Stack-up analysis should also be in line with any industry requirement and regulations, which may differ tremendously depending on the industry and geographical location. These requirements are critical factors of successful implementation in the global markets.

Tolerance theses that are induced in the international standard, e.g., ISO 14405, ASME Y14.5, make their specification and analysis consistent across industries, including tight individual component tolerances statistical tolerance analysis methods. Observing these standards is essential in creating global trade and it minimizes technical barriers nominal dimensions.

All of the requirements that govern the use of stack-up analysis should be met, such as documentation, validation of results, and traceability of the companies which operate in the regulated industry tolerance stack up analysis.

Conclusion

Stack-up analysis is a core field in engineering, and it closes design intent versus the reality of making a product. It is properly implemented to guarantee quality, lower expenses, and guarantee profitable global manufacturing activities. With the complexity of manufacturing expanding and being internationally dispersed, the emphasis of sound stack-up analysis is taking precedence.