This is an in-depth description of injection molds manufacturing process, including design principles, materials, and the use of a reciprocating screw for producing injection molded parts, quality control of injection molds as well as cost savings. Professional perspectives to manufacturers and engineers.

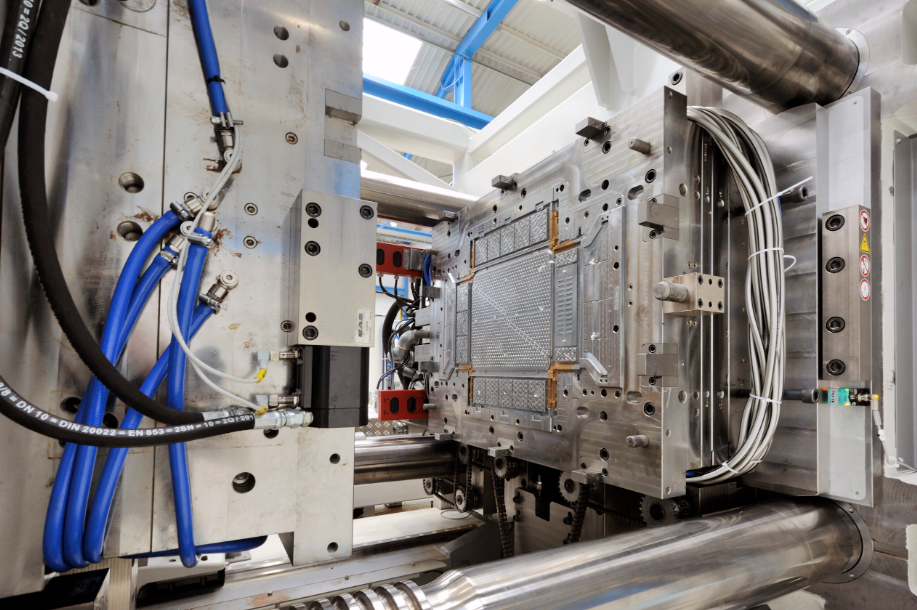

The injection molds manufacture is one of the most vital parts of contemporary plastic production, which allows for mass production of plastic parts in large amounts, with extraordinary precision and affordability. This all inclusive production has transformed a wide spectrum of industries including car industries, medical equipment devices, consumer electronics as well as packaging. The subtlety involved in the production of injection moulds requires an examination by engineers, designers and manufacturers who wish to maximize on their manufacturing opportunity and realize a high level of product performance.

Injection molding industry keeps changing with implementation of technological advancement, new materials, and ever-more complex design needs excess material. The latest injection molds production requires well-versed knowledge of injection molding design, science materials, accurate engineering, and the operation of the injection unit in the end-up manufacturing process to provide the developing requirements of the current competitive market.

Understanding Injection Molds Manufacturing Fundamentals

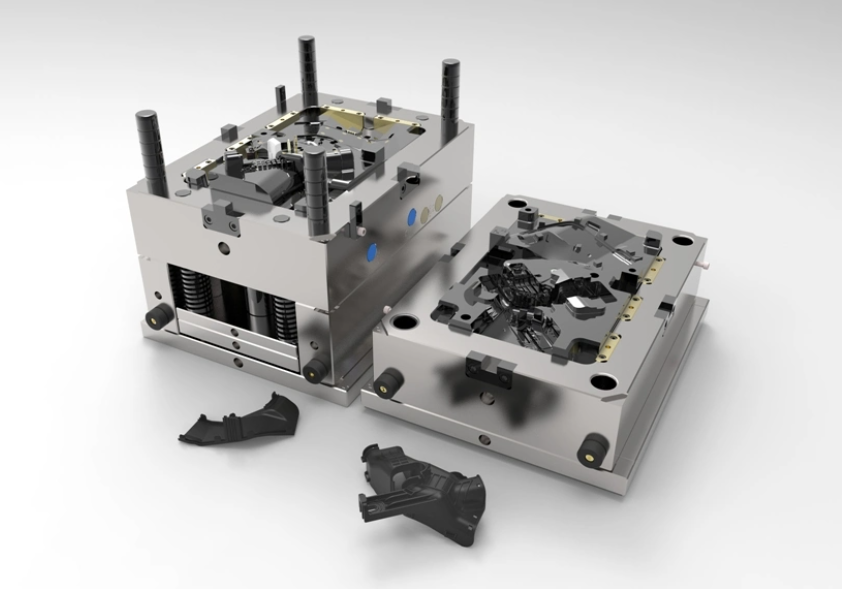

To proceed with injection molds manufacturing, it is essential to realize basic rules which this complicated process is to be based on. In its essence, injection molding implies designing accurate metal toolings that help form molten plastic into thin walls and final parts. The manufacturing operation has to be carried out taking a close look at the properties of materials, geometry of parts, and requirements of manufacturing to produce the best solutions.

Good injection molds design engineering, precision machining, and quality control systems integration is what makes the production of successful injection molds. Contemporary plants are equipped with computer-aided designs (CAD) computer numerical control (CNC) machining and more sophisticated measurement tools so that the tooling surfaces of injecting moulds meet the narrow tolerances of the quality tools.

Essential Design Principles for Injection Mold Manufacturing

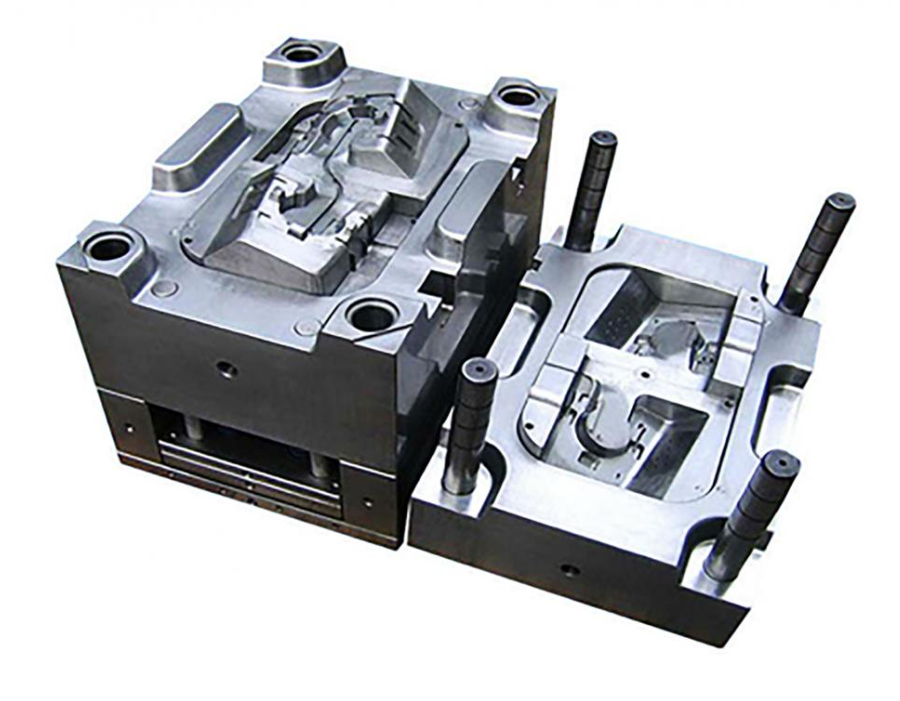

The pillar of a successful injection molds production is its design principles. Correct design in the early phases would highly influence the efficiency of production, quality of parts and the total cost of production. Important changes involve achieving uniform wall thickness, wall thickness homogeneity, draft angles, gate locations and optimisation of the cooling system.

Injection molds manufacturing is significantly dependent on the thickness of the walls, particularly when a thin layer exceeding normal is present, since changes in this parameter may result in sink marks, warpage, and uneven filling. By trying to keep the mold cavity wall even all thorough the part design we can make sure that there is even cooling throughout, making defect less to manufacturing.

Material Selection in Injection Molds Manufacturing

Selection of the plastic material is an important step in the production of injection molds which directly influences the tool life, part quality and cost of production. Typical materials used in molds for producing items such as bottle caps are ready grades of tool steel, aluminum alloys and performance/durability enhancing specialized gel coats.

High-volume production molds would still prefer a good steel material, owing to the high tolerance of wear and good thermal properties and the resistance to repeated cycle of thermal-influenced dimensions change. Aluminum molds have the benefit of prototype and low volume manufacturing requiring quicker machining durations in addition to low set-up expense, especially when the injection speed set is optimized .

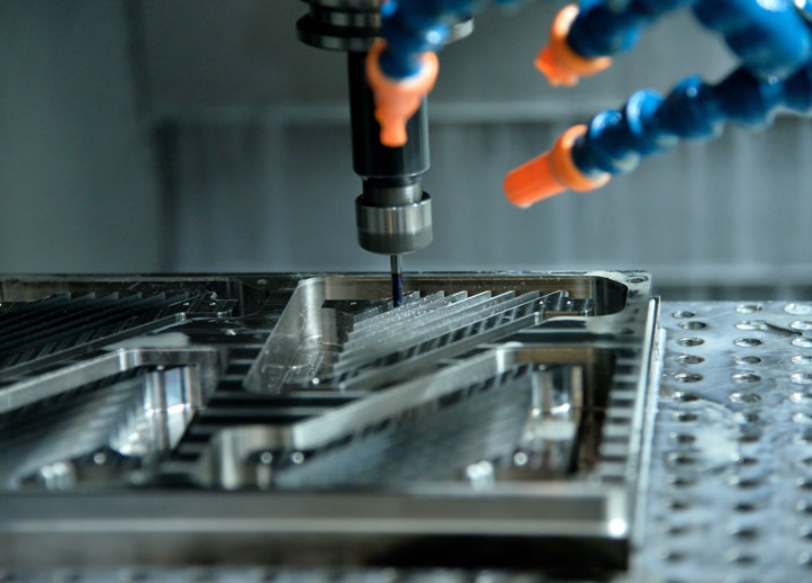

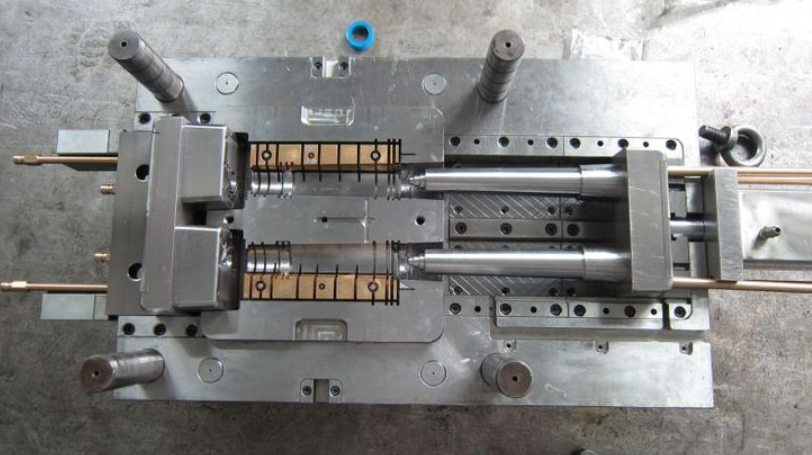

Advanced Machining Techniques in Mold Manufacturing

The present injection molds manufacturing is basically dependent on high level machining options, including electrical discharge machining, in order to provide high performance tools for the injection molding machine with precision and surface quality. Multi-axis CNC machining center can deliver the highly complex geometry with superior precision, which is crucial for the effective functioning of the injection ram .

EDM is also very crucial in the production of injection molds, more so when it comes to the formation of fine details, sharp edges as well as deep holes, which are hard to attain through the traditional machining processes. The wire EDM and ram EDM methods offer complementary advantages on the various processes of manufacture of molds, contributing to the cosmetic appearance of the finished product .

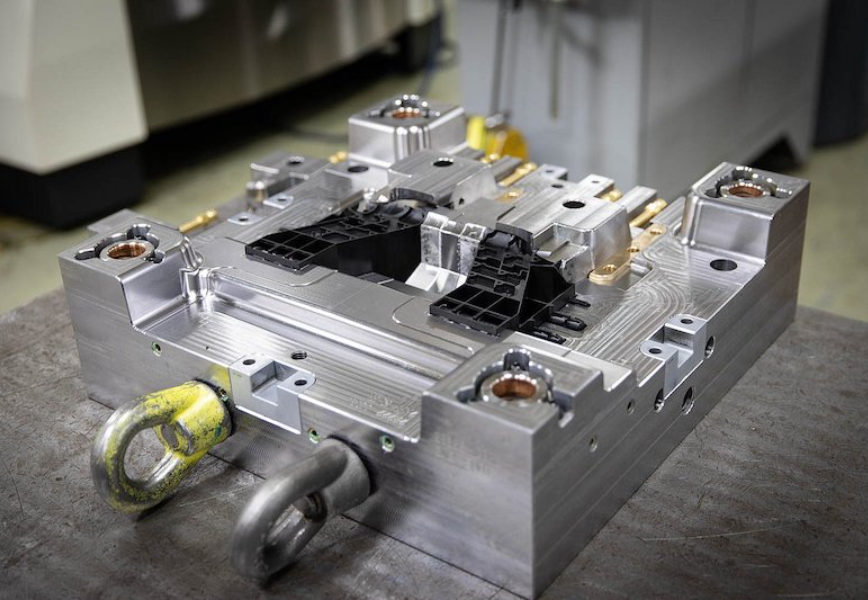

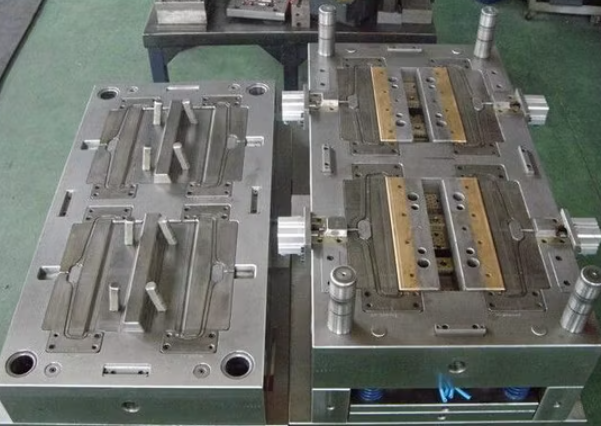

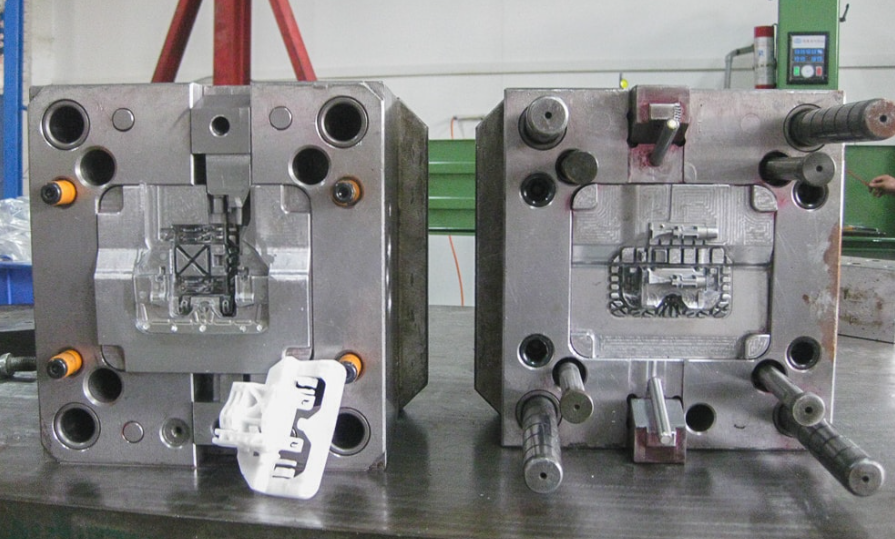

Tooling Fabrication Process Overview

A systematic procedure can be used to describe the fabrication of tooling that occurs in injection molds manufacturing, and this begins with the design analysis process that entails construction in detail and move to various stages of manufacturing, including 3d printing for rapid prototyp . The first measures involve the preparation of the material, crude machining, and heat treatment to create the main framework of the mold and the material that needs to be achieved.

Precision finishing processes will be the last processes of tooling manufacturing, especially in relation to the gate and runner system, with fine machining, polishing, and surface treatment procedure which will define the end-machine part and mold efficiency. Special machineries including the injection molding machine and highly trained technicians are needed in these operations in order to meet the specifications required.

Quality Control Systems in Mold Manufacturing

Successful injection molds manufacturing requires quality control systems that make sure that the completed tools are within the requirements on the specification and act reliably over their operating lifetime. In general, engineering quality plans contain incoming quality, in process quality, and post-quality inspection, which may require more injection pressure to ensure optimal results .

Mass produced, coordinated measuring machines (CMMs) offer accurate dimensional inspection with regard to complicated mold forms, whereas texture and polish inspection systems offer assurance that the requirements of the texture and polish are fulfilled. The quality systems have been designed to motivate costly delays in production as well as the guarantee to achieve a consistent part quality, especially around sharp corners .

Injection Molding Process Fundamentals

Injection molds manufacturing requires an knowledge of the injection molding process because the design of the injection mold should incorporate the physical and thermal demands of the molding process. It uses molten plastic resin being heated to a molten state, then injected into the mold cavity under pressure and then cooled and solidified.

Mold design issues like injection pressure, temperature, and cooling time are a couple of the process parameters that must be carefully impacted in order to produce a high quality part and meet the intended production. Running the systems allow easy and uniform filling and reduce wastes of materials through proper gate designs.

Thermoplastic Materials and Mold Compatibility

Injection molds manufacturing using thermoplastics and liquid silicone rubber have certain issues because each resin shrinks and has distinct thermal characteristics and possibly different chemicals involved in its chemical compatibility. Being aware of how different materials behave and their typical hardness ranges is important in designing molds to achieve part accuracy on a dimension.

The typical thermoplastics are ABS, polycarbonate, nylon and polypropylene all of which necessitate special consideration of mold due to their individual processing requirement. The choice of the material influences the requirements of the mold steel, cooling system, and finishing surface treatments, which are vital for the quality of molded parts .

Cooling System Design and Optimization

Design of cooling systems for thin walls is one of the important features of injection molds manufacturing that significantly influences the design of injection molding gates, cycle time, quality of parts and the entire manufacturing process. Optimal cooling processes will extract the heat evenly off the part molded, to reduce the warpage as well as speed up the cooling cycles.

Newer channel designs such as conformal cooling systems developed using additive manufacturing approaches provide a more efficient heat transfer, and higher temperature uniformity. Such advances in the cooling system design add to increased productivity and part quality.

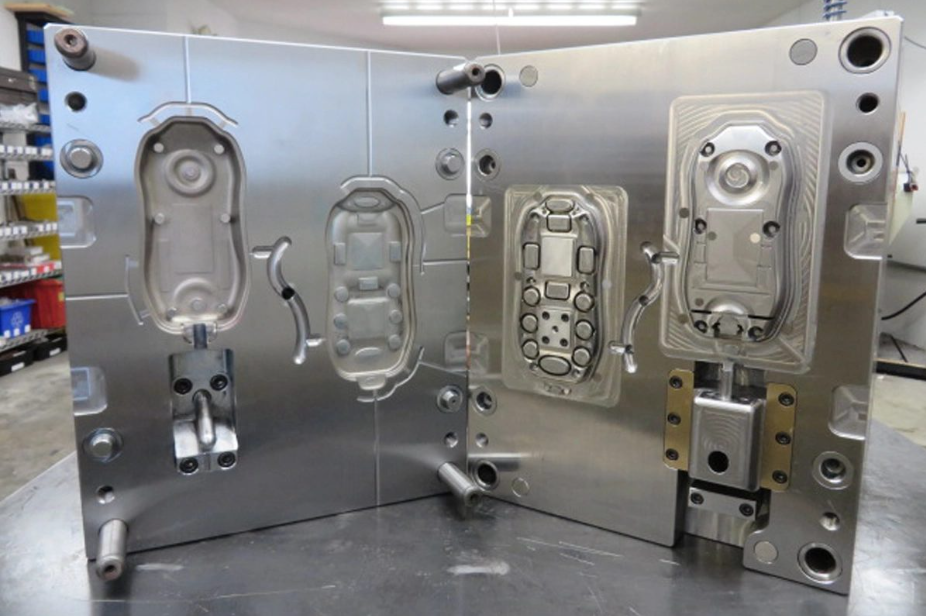

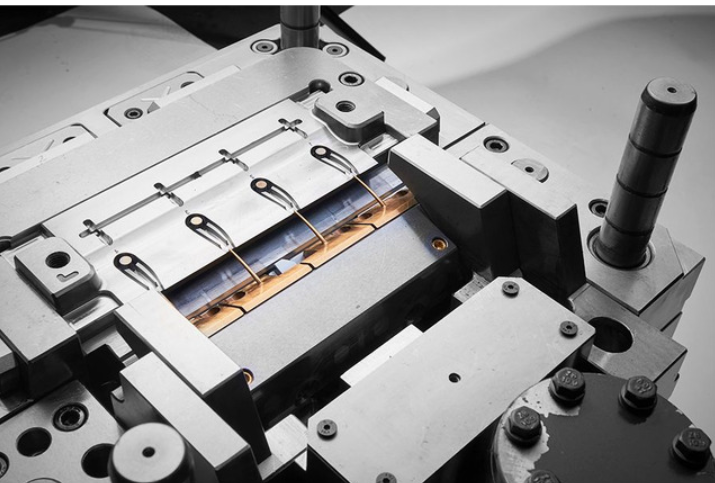

Gate Design and Runner System Engineering

Gate design and engineering of runner systems are the main aspects of injection molds manufacturing that affect the quality of the parts, material consumption, and efficiency. Well designed gates symmetrically fill so that few gate marks appear on machined parts.

The design of the run system should address the needs of material flow as well as waste reduction. Hot runner systems also remove waste of the material in conventional cold runner designs, eliminating empty space, plus they also offer better process control and shorter cycle times plastic injection molding.

Surface Finishing Techniques for Injection Molds

Effector conditions of injection molds manufacturing define the appearance and the working qualities of molded parts. There are a number of finishing techniques that can be used including high-polish surfaces used in optical applications or textured finishes which enhance grip or conceal cosmetic blemishes manufacturing plastic parts.

The polishing operations are usually carried out in several steps culminating in mirror surfaces by using finer and finer abrasives. Controlled, patterned textures (such as laser texturing and chemical etching) are used to add functionality and aesthetics properties within a controlled surface texture ejector pins.

Tolerance Management in Mold Manufacturing

Another important issue of injection molds manufacturing is tolerance management, particularly for thick walls, and it needs to be thoroughly thought through, referring to the material physical properties, machining capabilities, as well as to assembly needs produce plastic parts. Small tolerances are always associated with good manufacturing facilities and experienced factory workers.

Standard injection molding tolerances apply a precision feature of with tolerance of +/-0.003 inches to standard features of +/-0.010 inches depending on size, material and functional requirements. Allocation of the appropriate tolerance when designing aid in ensuring the manufacturability and the economical injection molding cycle.

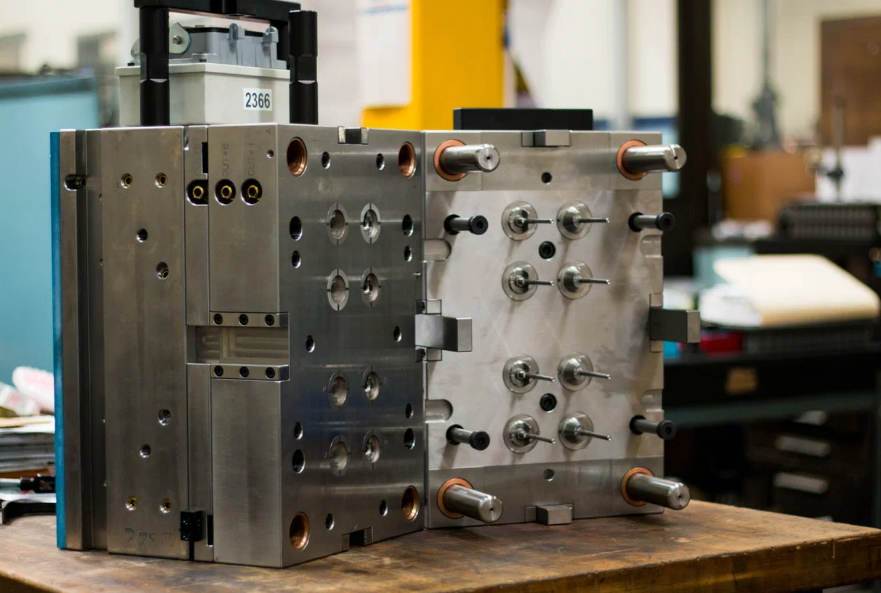

Assembly and Testing Procedures

The procedures of assembly and testing in injection molds manufacturing will guarantee that they work and perform to the special requirement before they are set up to complete the production process. Procedural assembly will maximize the prevention of errors and extensive testing of molds is carried out to certify their performance injection molding material.

Have a trial run by production materials and conditions of processing to give a feedback on the performance of the mold and corrections that might be needed. The trials also assist in the fine tuning of the processing conditions and to ensure that the parts coming out of the mold are of the required quality parting line.

Maintenance and Lifecycle Management

Lifecycle management and maintenance strategies are some of the most important in maximizing the investment in injection molds manufacturing business. Preventative maintenance programs assist in making the molds last longer and reducing any downtimes and cost of repairs that may be unexpected.

Frequent maintenance schedules, adequate cleaning methodology and an appropriate replacement of wear parts assist in prolonging mold performance. Maintenance records and maintenance performance indicators allow informed decisions on the maintenance of molds to be made using evidence.

Cost Optimization Strategies

Some of the cost optimization approaches in the injection molds manufacturing process entail the linkage between the influencing factors of initial tooling cost and long-term production requirements and production quality. There are several ways of minimizing the total production cost and upholding the quality standard.

Mold complexities and manufacturing cost can be reduced with the help of design optimization technology such as part consolidation and feature simplification. The material choice should take into account initial cost and long terms performance considerations to maximize the total costs of ownership.

Technology Trends in Mold Manufacturing

The direction on injection molds manufacturing technology has been going through changes as the manufacturing equipments, materials, as well as the design software advance. Conformal cooling channels and rapid prototyping applications also use additive manufacturing techniques more and more.

More efficient process of mold designing and production is facilitated by digital manufacturing technologies such as simulation programs and real time monitoring systems. The technologies lead to shortened development rates and enhanced first-time quality.

Automation in Injection Mold Production

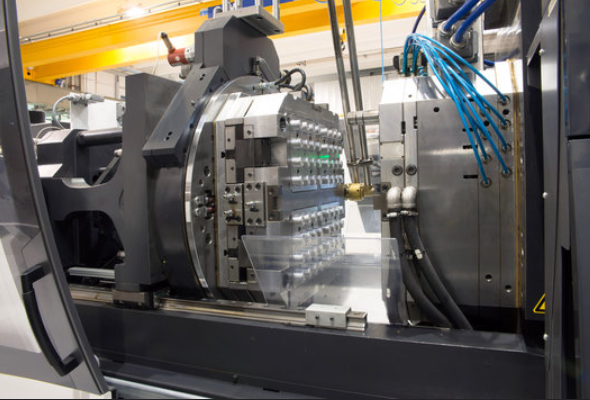

Automation in the production of the molding machine helps in promoting uniformity, low costs of labor, and overall efficiency of manufacturing, which can be optimized by adjusting patterns injection speeds . Automated machining systems have the feature of running with minimal supervision continuously and at high precision.

Robotic machines are also being applied in handling materials, inspection of parts and finishing. Such automated systems create better consistency in the quality of the products and smaller manufacturing lead times.

Environmental Considerations in Mold Manufacturing

Efforts are on a rise to have environmental considerations in injection molds manufacturing as successive firms are looking forward to minimizing their environmental impact. Sustainable manufacturing would involve recycling of materials, energy efficient manufacturing and reduction of wastes.

Green manufacture programs aim at reducing adverse effects on the environment without jeopardizing the quality and cost targets. Such efforts tend to bring along with them efficiencies and cost savings associated with operating in addition to being environmental friendly.

Industry Standards and Regulations

Different rules and regulations including industry standards apply in the process of injection molds manufacturing, especially regarding hot tip gates, to ensure safety, quality and interoperability. Manufacturers in such regulated facilities as medical devices and automobiles must adhere to the applicable standards.

Quality management systems and manufacturing procedures can be defined according to ISO standards, ASTMs specifications and requirements concerning industry. Awareness and application of these standards would go a long way to make sure that the products are acceptable and also comply with the required regulation.

Safety Protocols in Mold Manufacturing

Injection molds manufacturing takes adequate safety measures that safeguard both the workers and the machineries and at the same time maintains quality production. The comprehensive safety programs are directed towards the risks in machine operation, material handling, and chemical exposure.

Adequate training programs will make personnel aware of the safety requirements and accustomed to the laid down procedures. Safety audit and incident analysis are usually done in a regular period to know the areas of improvement and to prevent accidents.

Advanced Materials for Injection Molds

High performance injection mould materials provide superior performance parameters as opposed to normal tool steels. Such materials can give better wear resistance, thermal conductivity or corrosion resistance in special applications.

Mold performance may also be optimized by special coatings and surface treatments to reduce friction or release behavior, or to give the coating chemical resistance. The selection of material must take into consideration both the performance and the cost factor.

Precision Measurement and Inspection

To ensure that injection molds have passed specification requirements, precision measuring and inspection systems are a required element. High-tech measurement technologies allow specific characterization of a complex geometry and surface features.

Recent injection molds have optical measurement system, tactile probes, and laser scanning technologies that offer a full inspection capability. With these systems, there is a better quality assurance and fewer errors during manufacturing.

Rapid Prototyping Applications

The implementation of rapid prototyping offers efficient manufacturing of injection molds allowing a shorter period of designing validation and development. Part design and processing parameter tests can be done using prototype molds to determine the most optimum processing parameters prior to investing in production tools.

The 3D printing technologies are becoming more frequent in the design of prototype inserts and testing of new designs of cooling channels. Such softwares are useful in streamlining mould designs lowering development expense as well as increasing time-to-market.

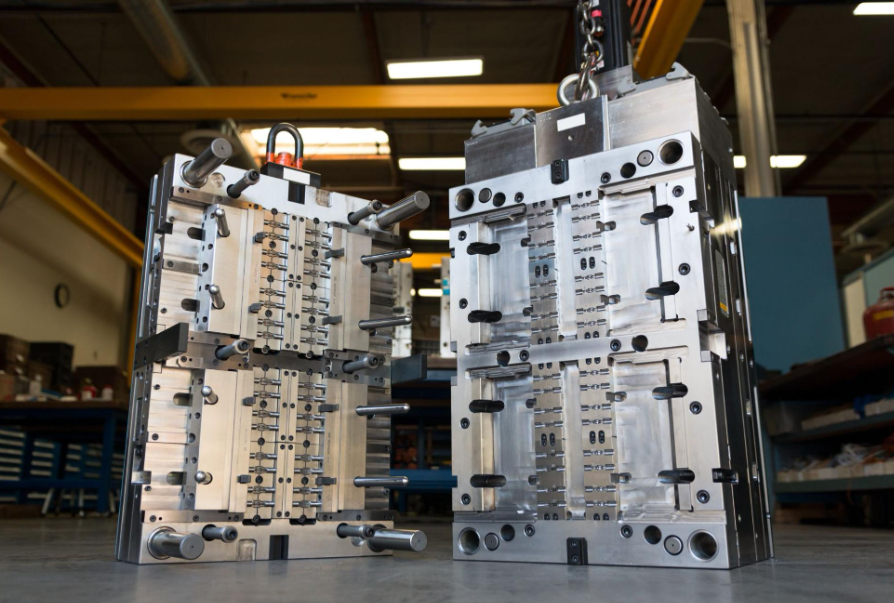

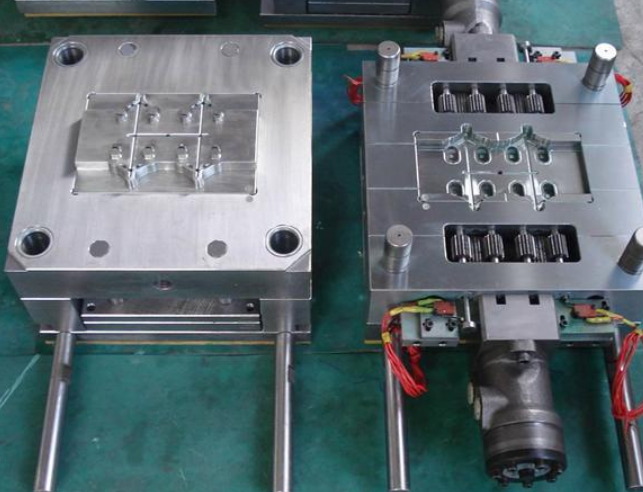

Multi-Cavity Mold Design

Design of a multi-cavity mold allows a set of parts to be produced at the same time which increases manufacturing efficiencies and lowers part-per-unit costs. Nonetheless, multi-cavity molds are very sensitive in terms of filling balance and tackling the temperature of the mold.

Gates and Gate sizing and runner balancing, including manually trimmed gates, become as critical aspect because of multi-cavity mould design so that all part is of same quality. The manufacturing process is enhanced through the use of sophisticated simulation software in streamlining these designs prior to actual manufacturing.

Hot Runner Technology

The Hot runner technology gets rid of wastage of material that is inherent in the conventional cold runner technology and it offers better control in the process and reduction in cycle time. Hot runner systems keep the molten plastic under check at the distribution system.

The precise cleaning control of plastic temperature and processable characteristics using temperature control systems and refined heating elements are possible. These systems assist in better part quality, as well as, low material costs.

Simulation and Modeling Tools

SMTs (simulation and modeling tools) devices are becoming widespread in the production of injection molds, as they allow a virtual testing and optimization before the physical manufacturing has started. Flow analysis software is able to forecast the pattern of filling, press requirement and defects that can arise.

Warpage character prediction and cooling system design optimization are possible using thermal analysis capabilities. These simulators help in better first-time quality and lowered cost of developing.

Future Outlook for Injection Molds Manufacturing

Future of injection molds manufacturing is that there will be further development of manufacturing technologies, materials, and design capabilities. Technologies of industry 4.0 will allow increasing the degree of networks and the optimization of production in real-time.

Additive manufacturing technologies will most likely have an increased value in molding production especially on complex cooling channels and rapid prototyping. Machine learning and artificial intelligence could also improve predicated maintenance and process optimization.

Troubleshooting Common Manufacturing Issues

Analysis of the symptoms and possible root causes referring to common manufacturing problems in injection molds is undertaken in a systematic fashion. When dimensional variations, defects on the surface of things and early wear occur, they are common problems.

Best troubleshooting strategies are used by matching process knowledge to methodological data gathering and processing. The approaches of root cause analysis can be used to define the background problems and avoid the emergence of the manufacturing issues.

Integration with Production Systems

The fact that it integrates with production systems means that it can make a smooth switch between the manufacturing of molds to production operations. Effective integration demands attention to be given to handling equipment, process parameters and requirements of quality.

Training and documentation helps to make production people aware of the specifications and requirements of molds. Integration will also lead to effective startup of production and performance.

Return on Investment Analysis

The analysis of the return on investment can rationalize investment in injection molds manufacturing since the anticipated benefits and expenses can be measured. Initial tooling costs, volumes of production, life cycle cost and quality enhancements must be analyzed.

On the basis of financial modeling techniques, one can compare various manufacturing strategies and also optimize investment decisions. The long term cost factors usually suggest increased investments in quality tooling.

Conclusion

Injection molds manufacturing is one of the highly integrated engineering skill and innovation, advanced manufacturing and quality regimes. The capabilities to understand material, processes and design and the dedication to better performance and innovativeness is essential in ensuring success in the field. New technologies, new materials and new approaches to the industry put pressure on the manufactures to keep up with new tendencies, without losing focus on primary goals-quality and cost of production.