Meta Description: Learn all about the core and cavity design injection mold and the role of cavity in injection molding to create a complete mold , its types and functions, as well as how it is produced. Understand the use of cavity and core elements to complex and high quality plastic parts accurately and effectively.

Introduction to Injection Molding Core and Cavity Systems

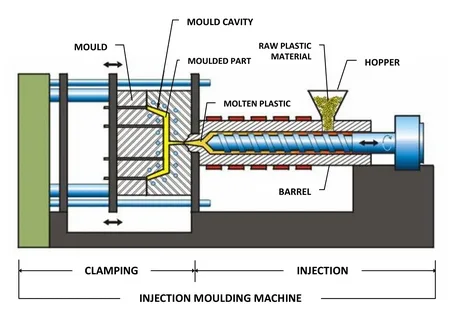

The core and cavity systems in injection molding are where it all begins, this is the core of precision plastic manufacturing and high quality formed parts begin with this system. In a beautiful symbiosis, these key elements make molten material into specified shapes, decides the accuracy of dimensions as well as the quality of surface finish. The manufacturers have to attain a high level of consistency in the production cycles and thus the intricate nature of their relationship is crucial in the evolution process.

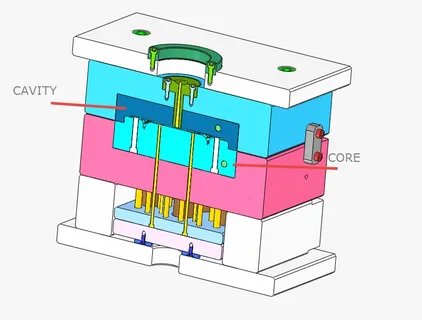

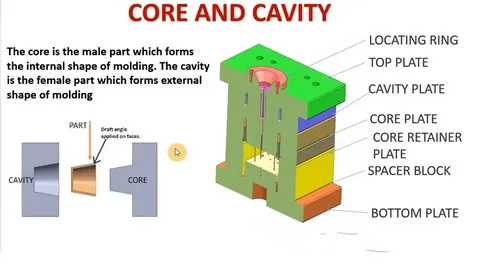

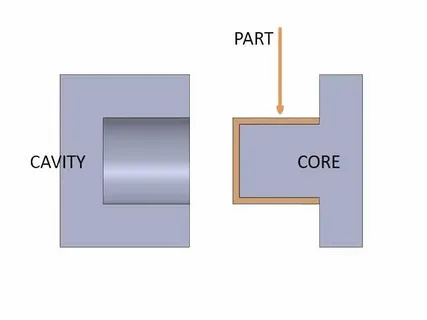

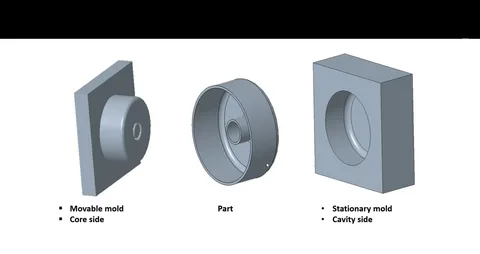

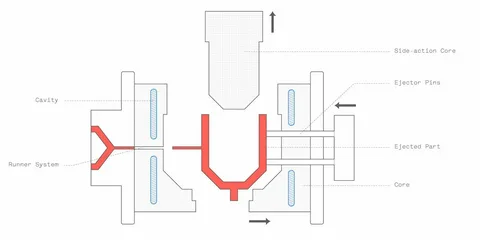

Core and cavity mechanism follows one of the basic principles that cavity makes the outer surfaces with newly enhanced features and the core form internal shapes. The nature of such a symbiotic production relationship allows the making of complex parts containing detailed features, hollow cavities and specific dimensional tolerances that could not be attained by alternative manufacturing processes.

Understanding the Core Component in Injection Molding

The core is the movable component of the injection mold and it develops internal features, holes, recesses, and intricate geometries inside the injection molded component, often aided by ejector pins. The core has to be built to withstand high mechanical stresses without the loss of precision through the entire molding cycle as opposed to the stationary cavity.

Central design involving attention in choice of material of usage, location of cooling channels, and ejection systems, as well as the design of the cavity plate, are of importance. The core should withstand deformation to high injections pressures and allow effective convection to reduce cycle times, emphasizing the need for proper design . Professional advances have usually glorified advanced core designs to include advanced cooling systems and special-coating arrangements to guarantee improved standards and cutting edge endures.

Exploring the Cavity Component in Injection Molding

The outer dimensions, texture, and final look of the manufactured part are set by the cavity as the non moving part of the mold system. This element is entrusted with the task of making the external features and aesthetic qualities which determine the product acceptability in the market place. and it is therefore vital in designing and construction in the manufacturing process.

The buildings of the cavity require extraordinarily high standards of quality, surface finishing, dimensional firmness, and controlling heat levels. The cavity has to be able to hold consistent temperatures through the molding cycle and rectify consistent cooling without warpage and dimensional variation. Good cavity design will guarantee good material flow patterns and remove possible defects i.e. weld lines and sink marks.

The Fundamental Importance of Core and Cavity Design

Good core and cavity design, including the use of three plate molds, has a direct relation to the quality of the product, efficiency in manufacturing and the total cost evaluation of production. These elements define the tolerances that can be met, level of surface finish and the strength of molded components. Incompetent design may lead to high scrap rates, extended cycle and short tool life.

The value is not only related to shorter manufacturing matters and is inclusive of long-range sustainability and competition. Core/cavity system design allows good quality parts with the desired external shape to be produced in a consistent manner and minimise material wastage and energy usage during the production process . This is economical in terms of environmental effects and profitability to the manufacturing companies.

Material Selection for Core and Cavity Construction

The choice of material used to construct core and cavities involves considerations of numerous variables, such as hardness, thermal conductivity, resistances to corrosion, machinability, and the ability to achieve the desired shape. The commonly used tool steels include; hardened steel H13, P20 and 420 stainless steel there are also advantages associated with the usage of these tools based on the application requirement.

High-thermal-conductivity such as advanced materials like beryllium copper and aluminum alloys are used in applications that require rapid cooling. Even more, performance can be further improved by a number of surface treatments and coatings, which improve the wear resistance, reduce friction, and inhibit corrosion. The choice procedure should also consider factors such as cavity placement, both the view of cost to begin with and efficiency over period of operation.

Types of Cavity Systems in Injection Molding

The system used in injection molding of the cavities can be generalized into various types each depending on the production needs. The single-cavity molds are the most flexible ones and they are suitable for the development of distinct components, prototype and churning of low volumes. Multi-cavity designs are more complex and hence cost more to purchase as well as achieve high rates of production due to simultaneous formation of multiple parts concurrently.

Family molds refer to special type of cavity which is used to produce various but similar parts in an individual moulding cycle. The method minimizes material use and lowers handling expense although attention must be paid to gate design and pressure balancing to make sure the quality of the part is uniform in all the cavities produced by the injection molding machine .

Core System Classifications and Applications

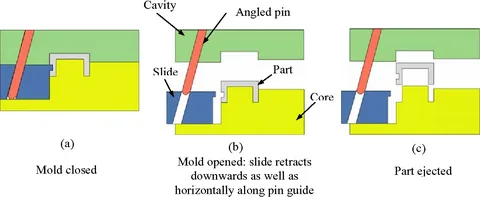

Core systems include a number of configurations that are used to deal with unique manufacturing issues. And fixed cores offer a very simple solution when simple internal features are desired, where full sliding cores and unscrewing cavities llow the formation of undercuts and non-desired complex shapes. Parts could also have internal threading or be hollow which is impossible to mold through a collapsible core.

Unscrewing cores form the most advanced type, having rotational capabilities which are used to form threaded features actual mold. Such systems in the mold assembly must have tight timing and synchronization with the overall molding cycle but can accomplish the final product without follow on secondary operations.

Design Principles for Optimal Core and Cavity Performance

Effective design of the core and cavity is a process that has had laid down guiding principles which are based on functionality, manufacturability and maintainability. Uniformity of the wall thickness can avoid any form of warpage due to the absence of differential cooling, and the correct draft angle will make it easy to eject the part without any form of damage, particularly when using wear resistant materials . The stress concentrations are also mitigated by Radius applications at corners and transitions that enhance material flow characteristics.

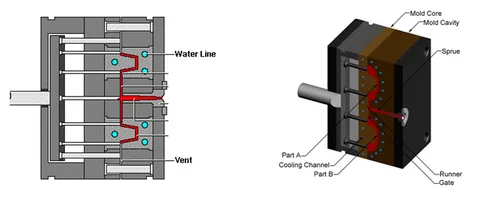

The design of venting will make sure that the cavity is filled completely, but at the same time, it will avoid the occurrence of air trapping in the mold half which may lead to such problems as surface imperfection or a partially filled situation. Gate placement and gate size must be a compromise between good filling and appearance needs, especially on visible surfaces where the minimal vestige of the gates is desired, and a plate mold requires careful consideration .

Cooling System Integration in Core and Cavity Design

Design of effective cooling system is one of the most significant factors of the core and cavity engineering. The use of cooling channels means, these areas should be strategically located in such a way that they are able to achieve effective control of temperatures without undermining the structural integrity of the mold parts that are being used. Complex geometries can also be further managed by implementing conformal cooling channels that are designed during such manufacture processes.

Efficiency of the cooling system has a direct bearing on the cycle time, part quality and general productivity. Poor cooling will lead to longer cycle times and quality problems and excessive cooling during the injection process may lead to pre-solidification of materials and filling problems. Thermal modeling software is an advanced technique that assists in the development of cooling effort to achieve optimal design.

Surface Finish Considerations for Core and Cavity

Quality of surface finish of core components and cavity components yields directly to the appearance and the functionality of the final part. Fine selection of machining process, polishing techniques and surface treatments to achieve desired surface texture is important. Mirror surfaces are extremely time consuming in hand polishing as well as dealing with specific techniques and textured can be chemically etched or laser textured.

Smoothness of the surface finish between the mold cavity will provide consistency with the appearance of the part with no visual flaws. Periodical overhaul and repairing of the surface finishes keep the quality of the parts constant till the life of the tool use and the gradual corrosion that might occur subsequently lowering the acceptance of the products.

Manufacturing Processes for Core and Cavity Production

Various high accuracy manufacturing processes used (core and cavity manufacturing) include CNC milling, electrical discharge machining (EDM) and and wire EDM. Both processes have their peculiar benefits relating to the complexity of the geometry, the hardness of materials and surface finishes. Most applications easily suit CNC machining that gives a lot of accuracy and surface finish, and the EDM can be used to create complex shapes out of hardened materials.

Compact manufacturing technologies have also seen the popularity of advanced techniques, including additive manufacturing, being applied to conformal cooling channels and otherwise complex internal geometries which would be either impracticable or time-consuming to machine traditionally, especially when using advanced materials . The innovative technologies allow new design techniques resulting in better performance and decreased amount of machining time and cost core and cavity placement.

Quality Control and Inspection Methods

Strict quality control procedures are having core and cavity parts that are characterized within the requirements and tolerances molten plastic. Dimensional accuracy is checked by coordinate measuring machines (CMM) and the quality of finish is checked by surface roughness testers. Hardness tests confirm that the heat treatment is effective, whereas the non-destructive test betrays any internal defects, which might interfere with performance surface quality.

Complex geometry of these surfaces can be effectively verified by such methods of inspection as laser scanning and photogrammetry. These techniques give complete documentation of as-built conditions and enable comparison to design requirements thus making sure it is in accordance to the quality standards.

Maintenance and Service Life Optimization

Core and cavity service time is increased and part quality is consistent with proper maintenance. Periodic cleaning cleans up leftover and avoids contamination that might happen to surface finish. Moving components are lubricated and this helps to ensure smooth movement as well as eliminates premature wear of critical interfaces molded plastic.

The schedules of preventative maintenance by shot count or scheduled maintenance by calendar interval aims at recognizing the possible problems before they can interfere with production. Close monitoring of the wear pattern, dimensional variations and surface condition allows reactive maintenance to ensure minimum of down time and quality of output.

Common Defects and Troubleshooting Solutions

Knowledge on the defects that commonly relate to the core and cavity design helps to understand the problem quickly, and it can be easily resolved. When Flash defects are found, it is an indication that the amount of the clamping pressure was inadequate or that the parting line surfaces were worn off; on the other hand the sink marks will tell you that the cooling was not adequate or that the wall basis was not properly designed mold structure .

The cause of short shots can be insufficient venting, insufficient gate design or improper injection pressure exterior surface. Effective systematic methods of troubleshooting that take into account the connection between characteristics of defects and possible reasons allow solving the problem soon and limiting the consequences of busting production mold parts.

Advanced Core and Cavity Technologies

New technologies allow further development of core and cavity designs as well. Additive manufacturing allows building intricate internal coolant and structure that enhances thermolelectric management and decreasing cycle time. Wear, pressure, and temperature conditions are monitored in real-time in mold components comprising smart sensors.

High-end surface treatments such as diamond-like carbon and special alloy lays are worn resistant and anti-friction fundamental components. The technologies are able to raise the life of tools and enhance the quality of parts and the production efficiency which are major engagements in injection molding competence.

Cost Considerations in Core and Cavity Design

Design of core and cavity needs to fulfill cost effective core and cavity needs, including whether to implement a two plate mold, to compromise on immediate investment with operational productivity hollow portions. Higher cost may be attributed to premium materials and intensive manufacturing processes that in most cases result in high-performance and low maintenance periods that outweighs the initial cost in terms of lowered maintenance expenses and replacement expenses.

Optimization of the design being economical of the material and preserving the structure can also greatly save expenses at the expense of not losing the performance. CAE software allow proper analysis of design options so as to determine the most economical solutions to given applications.

Multi-Cavity Mold Design Strategies

Multi-cavity design of mold poses special difficulties in producing high-quality parts replication in all the cavities. The balanced running systems guarantee uniform distribution of material and pressure, whereas the individual cavity temperature control guarantees the uniformity of cooling conditions. The gate design and the size should consider the possibility of the pressure and material property change during the filling process.

Software with a high level of simulation assist in fine tuning the design of multi-cavity in anticipating flow patterns, pressure profiles, cooling effects. This is an analysis that allows the refinements in the design that increases the consistency of the outer shape and minimizes the possibilities of cavity to cavity variations that may lead to poor parts.

Insert Molding with Core and Cavity Systems

Special core and cavity forms of insert molding are necessary to bind pre-formed parts in fixed position and covered by the plastic material inserted into the mold. There are precise positioning mechanisms that place that place the injection in the correct positions so that they are not displaced during the injection. The changes to the core and the cavity adopt the geometry of insert, but ensure reasonable sealing and ejection behavior, which is often enhanced through mold polishing .

In the insert molding, particularly, thermal management may be a determining factor because various materials and coefficient of thermal expansion should be taken into account. Insert molding will fail unless design strategies are developed to minimize producing thermally intensive volumes in the mold, as well as still provide an adequate material flow around inserts.

Environmental and Sustainability Considerations

Design concept for the modern core and cavity is paying more and more attention to environmental impact and sustainability. An eco-emphasis on the selection of materials focuses on recycling and environmental friendly processes, and the optimization of the design of the material aims at minimizing the usage of material and energy in production, especially when the mold consists of two halves . The long life of tools due to better design and material lowers the replacement rate and costs on the environment.

The overall energy consumption of the part produced is minimized by use of energy-efficient cooling and minimized cycle times. Such considerations are consistent with the expanding environmental awareness and compliance-based services combined with frequent economic advantages derived by reducing the operation costs.

Future Trends in Core and Cavity Technology

Digitalization, automation and advanced materials expand technological opportunities ahead in the development of core and cavity technology. The concepts of industry 4.0 facilitated through built-in data analytics and sensors allow performing real-time maintenance and optimization of Mold operations. Applications of artificial intelligence can also optimize the design parameters and foretell possible problems, such as ejection pin marks that will not interfere with production.

New materials such as advanced materials, nanocomposites and smart materials have supplementary potential to drive performances and functionalities. These trends will extend into the further development of what can be done in the field of injection molding and enhancing the aspects of efficiency and sustainability.

Conclusion

Injection molding core and cavity assemblies are the backbone of the precision plastic production, their direct impact on the part quality, efficacy of the production and manufacturing costs. To consistently apply these and remain competitive in the modern competitive market, efficient grasp of their designing principles, choice of material, manufacturing, and maintenance issues is inevitable.

A proper implementation would involve multiple aspects that should be put into consideration such as material characteristics, thermal control,ability to manufacture and sustainability after the implementation. Manufacturers could optimise their core and cavity systems to achieve the best performance and profitability through the use of established principles of design strategy as well as the use of technologies.