Finishing sheet metal components is one of the most important processes in the manufacturing process, since it takes rough metal parts and verifies them into sensible, reliable and eye-pleasing objects. This overall treatment improves not only the cosmetic aspect of metal components, but also greatly increases their performance attributes; such as chemical resistance, corrosion resistance, wear resistance, etc, and also with respect to their overall life cycle.

The competition in the current manufacturing sector necessitates the knowledge of the available alternatives in the sheet metal finishing process by businesses that aim at maximizing the quality of their products at a cost-effective manner. Whether used in automobiles or in architecture, the correct finish application can come between a good functioning product versus an excellent product used in its application, especially for nonferrous metals .

Understanding Sheet Metal Finishing Fundamentals

Sheet metal finishost-processing, the sheet metal part may be subjected to finishing procedures using sheet metal finishes. Such processes are applicable in many ways such as protecting the sheet metal surface, improving aesthetics and even providing functionality.

Different types of finishes are chosen based on factors such as the underlying material, the purpose to which the product is to be put, the surrounding conditions of the environment, limitations of cost and the required outlook. All of these finishing methods, including brushed finish, have their own special benefits and they can apply better to some applications than to others.

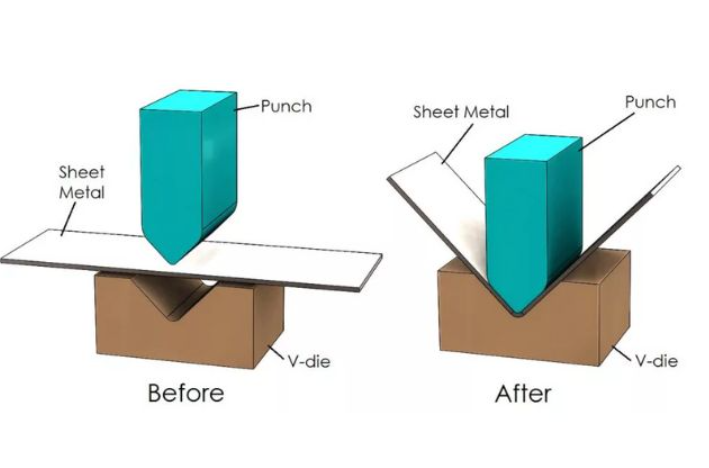

Contemporary sheet metal finishing processes may be generally classified into subtractive (in which abrasive materials are used to remove material on surface) and additive (in which material is added to surface). These are the basic differences, including waterjet cutting, which a manufacturer can understand in order to make sound decisions regarding the most appropriate finishing method that fits his or her needs.

Raw Finish: The Natural Metal Surface

Raw finish Raw finish is where no extra finish process is added to the final sheet metal item; sometimes referred to as mill finish or natural finish. This design is usually selected in cases whereby the base material already has the requisite characteristics to fit in its target environment and use.

Raw finishing is favorable at stainless steel components, as they are renowned corrosion resistant in their nature and also robust. This last is a very popular choice of finishing specifically in those applications in which the natural properties of the metal are adequate to satisfy performance demands without further treatment.

The pharmaceutical manufacturing industry, the chemical processing business as well as the food processing industry are examples of industries that mostly use raw finishes on the stainless steel type of equipment because the nature of these industries is to be resistant to contamination and the ability to be cleaned with ease. Raw finishes are cost-effective, which suggests their application in cases such as industrial equipment that pose little priority on aesthetics improvement.

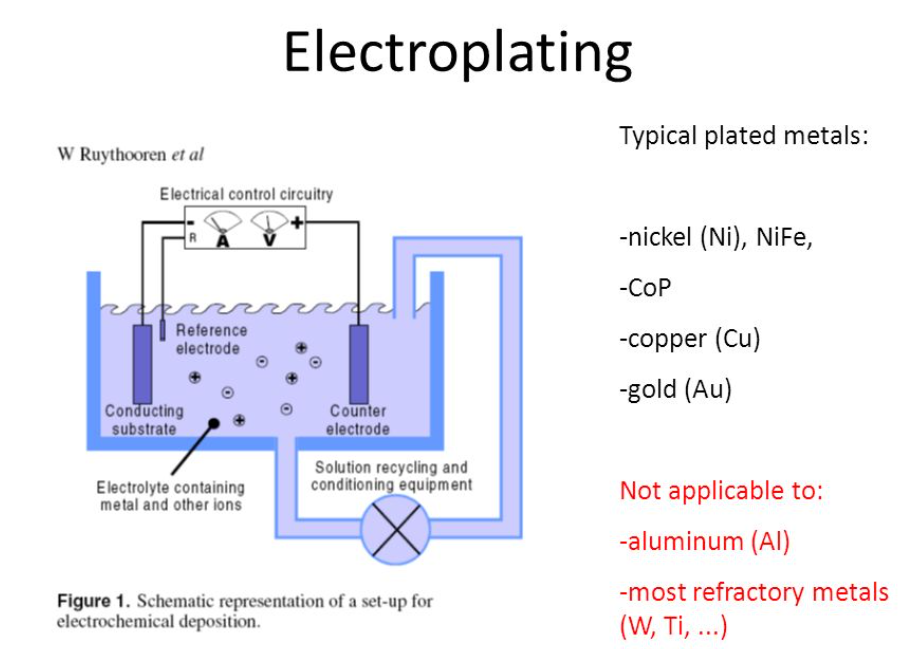

Electroplating: Precision Metal Coating

Electrodeposition (also called electroplating) consists of one of the most valuable and commonly applied techniques of finishing of the manufacturing part. It is in the form of placing a thin coating of a different metal on the surface of the sheet metal called substrate, by using electrochemical method.

The electroplating process provides the ability of extremely controlling coating thickness, uniformity, coating properties. Standard plating materials are chrome, nickel, zinc, gold and silver. Every plating material, including anodic oxide, contributes certain features to the end product like increased protection against corrosion, improves corrosion resistance better conductivity, and better looks.

Electroplating is used widely throughout many industries, such as decorative chrome over the automotive parts, protection against rust by zinc on construction hardware, etc. This process in specific is appreciated due to the possibility of uniform coverage on complex geometry as well as the ability to work with high-volume production needs, which can be enhanced by using sacrificial anode technology .

Bead Blasting: Achieving Uniform Surface Texture

Bead blasting is a delicate controlled abrasive finishing in which small beads of glass or ceramic media is forced at high velocity to surface abrade and texture sheet metals. The process is not very aggressive as the other more conventional sandblasting process but it manages to eliminate the surface flaws and tooling marks efficiently to achieve a smooth finish .

The bead blasting process offers a smooth appearance that gives the material a even matte look preferred on applications that need to have a even surface texture. The method is very useful in the removal of oxidation, paint and other surface contaminants using non woven abrasive materials, although someone may use it to prepare the surface to be applied with other coats.

Bead blasting is commonly used in industries to get desired textures on the surfaces such as automotive industries (car manufacturing, furniture manufacturing, and architectural use). This process is particularly useful in generating surfaces, especially on stainless steel, where a maximum bonding strength of paint or coatings is desired since the surface roughened a little bit offers an exceptional mechanical bonding capacity.

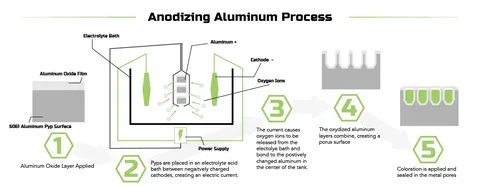

Aluminum Anodizing: Electrochemical Surface Enhancement

Anodizing involves the addition of a coating, thicker and oxide layer, to aluminum so that it cannot be attacked by weather or rust. This is an electrochemical technique that turns the surface of the aluminum into a tough layer of aluminum oxide which greatly boost the corrosion properties and wear properties.

Anodizing process may be categorized into three following bases; type I (chromic acid anodizing), Type II (sulfuric acid anodizing) and type III (hard anodizing). All the types have varying features concerning the thickness of the coating, stiffness of the material and look, and thus, the manufacturer can pick the best that suits his or her needs.

Anodized aluminum products find wide usage in architectural products, electronic housing, automotive components and goods. Not only does the process result in high protection, but also due to the ease of lining dyes the process can produce many colors making it favorable to decorative uses as well as practical.

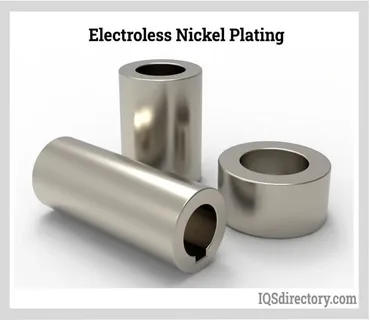

Electroless Plating: Chemical Metal Deposition

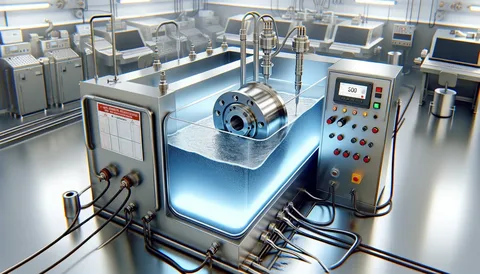

Electroless plating (also called auto- cathodic plating) is a special alternative to conventional electroplating to produce metal coatings using non-electric chemical reactions. The process places the metal ions in a chemical bath and through the reduction, it produces a thin uniform coating and the use of electrical contact is not necessary.

The main advantages of the production of electroless plating are that it provides uniform thickness, it is used to process complex shapes, it does not form any sludge and it is highly corrosion resistant. The technique is specially useful in coating non-conductor and applying a thin layer of uniform coating on complex parts where there are deep recesses or openings to enhance durability .

Electroless plating finds applications in a wide range of industries from automobile such as in brake parts, aerospace in precision parts and manufacturing tools and dies, electronic in circuit boards to name a few. The process is particularly appreciated in processes that require sides to be coated uniformly in order to ensure performance.

Powder Coating: Durable Dry Finishing

Powder coating is among the most viable and environmentally friendly finishing methods available for sheet metal parts. This is done through application of a dry powder (resin, pigments and additives) in an electronic manner to aluminum parts, after which it is thermally cured to make a cross-linked polymer finish.

The advantages of the powder coating process are many such as, good durability, eco friendly (none of the available VOCs), and can accomplish thick coats within one job. The finish offers high chip resistance, scratch and fade resistance as well as a uniform finish with variety of color and texture to choose among.

Powder coating is very much used in industrial, appliance, automotive and architectual items because of better performance attributes. It is also especially fit to the high-volume production, and is quite cost-efficient when carried out on a large scale

Phosphate Coating: Corrosion-Resistant Base Layer

Phosphate coating (or phosphatizing) is a crystalline coating of steel surface using chemical treatment with phosphate. It gives superb adhesive qualities of any further paints or coating and inherent corrosion resistance.

The phosphate coating procedure is that of usually zinc phosphate, iron phosphate and manganese phosphate being used to form a conversion coating that chemically reacts with the steel base. The finish that results is gray to black which serves as an outstanding substrate on which organic coatings can be applied with a limited level of corrosion protection even by itself.

The highest volume of applications of phosphate coating is in the manufacturing of automotive where body panels and structural parts are coated which need the best adhesion of the paint used. This process is also applied in the manufacture of appliances, all over the general industry and applications where high coating adhesion is needed.

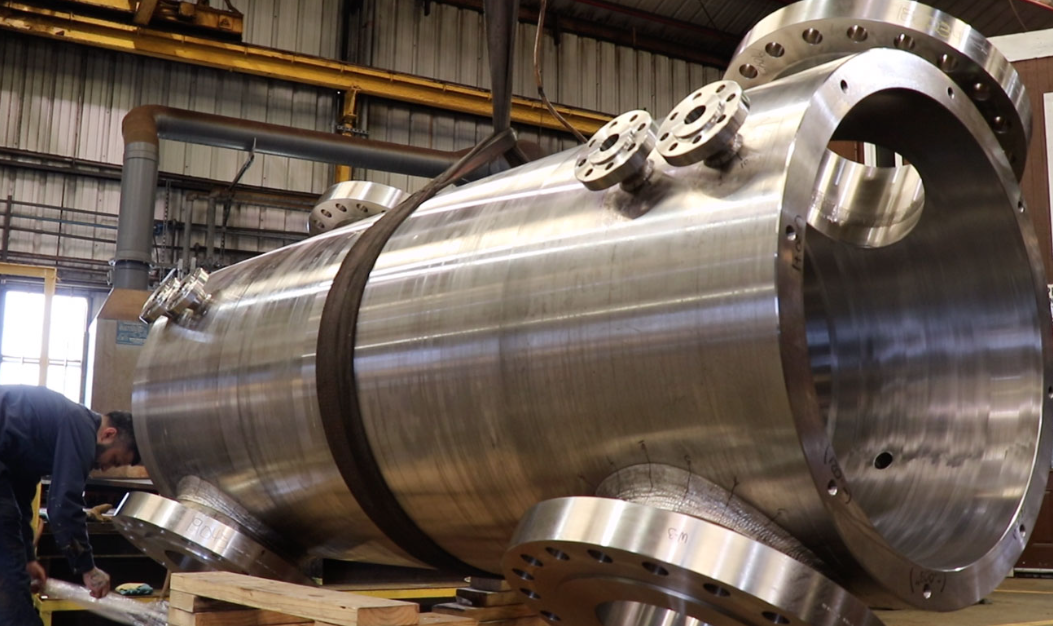

Electropolishing: Precision Surface Refinement

Electropolishing is an electro-chemical method of surface preparation that removes less desired material selectively from a metal surface leaving the surface finish extremely smooth, bright, and clean. This represents simply the opposite of electroplating whereby electrical current is utilized in dissolving the physical abnormalities and impurities on the surface.

Electropolishing process has myriad advantages such as corrosion resistance improvement, decrease in surface roughness, removes the surface contaminants, and having better cleanability. It is a very useful technique in any form of use where sanitness or high quality surface is required.

Electropolishing is used regularly in medical device manufacture, food processing equipment, pharmaceutical manufacture, and semiconductor fabrication to meet the very high levels of surface quality demanded in such important applications. The process finds particular importance where corrosion resistance and cleanliness is most important, especially when applied to mild steel parts .

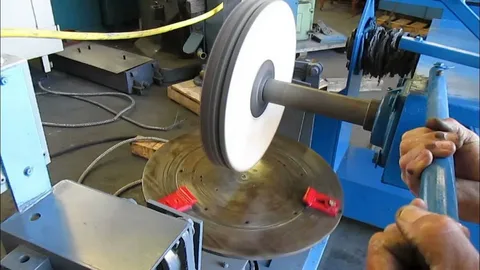

Buff Polishing: Mechanical Surface Enhancement

Buff polishing involves the use of rotating cloth wheels that are loaded with car polishes in order to provide smooth and reflected surface finishes of sheet metal parts. Mirror-brighted as well as satin finishes can be generated through this mechanical finishing process (surface).

The buff polishing process is very versatile and open to modifications to attain certain specified needs in surfaces. Various types of polishing compounds and wheel material can be selected to configure the final surface look and quality. It is especially suitable in providing decorative finishes and it removes small variations in the surface.

Buff polishing is also common in food service equipment, architectural hardware, decoration components and high-end consumer goods to produce a high-quality surface. It is particularly appreciated in processes that aim to produce an image that is very vital in accepting a product and positioning it in the market.

Abrasive Blasting: Comprehensive Surface Preparation

Abrasive blasting involves a wide series of methods that involve a high velocity media blasting abrasives to clean, texture, and polish sheet metal. Sandblasting, shot blasting and media blasting all come under this category and are all highly optimised to suit an application and a surface treatment.

The abrasive blasting process accomplishes two things as it cleansse the surfaces and leave them at the best finish in relation to follow-on coating. It is exceptionally effective in stripping rust, paint and scale and other surface impurities as it prepares the surface to adhere to the coating.

Abrasive blasting finds very wide use in construction, marine, automotive as well as heavy equipment industry in the application of surface preparation and restoration. The method is especially useful when applied to a large project since it is more important in the high efficiency of surface preparation to the success of the projects in general and the coating performances.

Surface Finish Quality Classifications

Order your sheet metal finished as one of grades A, B, or C the grades represent best, better and good in respect to finishing quality: Class A is of the best and finest finish, and is always the most expensive finishing: Class B gives a slightly less fine surface, and is a cheaper finishing to Class A: Class C is a coarser finish than either and always the cheapest: These classifications are commonly used by the manufacturer to state grades of finishing required by the customer; but they should not be confused with the names of the various classes of galvanized sheet, 2

Class A finishes are the best grade, and as a rule, they undergo an extra processing, and quality checks are needed. Such finishes are required in exposed parts, luxury uses, and in instances whereby the surface quality is directly involved in the performance of products or customer values.

Class B and C finishes offer increasingly cost effective alternatives without compromising performance. Being aware of these classifications means manufacturers in sheet metal fabrication can balance the expenses with sufficient surface quality according to defined applications and the requirements of customers.

Selecting the Right Finishing Process

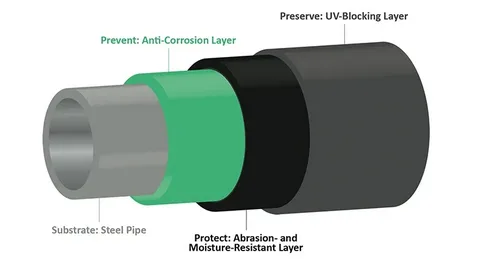

Selecting a sheet metal finishing process needs to be selected with a lot of consideration in many factors such as compatibility of the materials, environmental considerations, aesthetic needs, performance requirements, and cost factor. Every finishing mode has its own benefits and restrictions that have to be proportioned with certain applications demands.

Environmental conditions are also critical in selection of finishes because exposure to moisture, chemicals, extreme temperatures, and UV Radiation have a tremendous effect on the performance and duration of the finishes. Appreciation of the service detail helps the manufacturers to use the finishes that will deliver optimum performance within the intended lifespan of the product.

Not only will it be considered as to how much it might cost to finish it, but as to the long-term costs involved in the event of any maintenance being required, what may be the cost of replacement, and what effect will it have on the performance of the product. Initial costs may be found to be higher with use of finishes of better quality, which gives better value over all in terms of cost analysis.

Modern Finishing Technologies and Innovations

Finishing technologies are progressing towards an improved efficiency and performance with newer materials, processes and quality control technologies involved. Advancement in nanotechnology, the smart coating and automation application systems are making its application in sheet metal finishing more possible.

Quality control systems have digitalized, and real-time observations of finishing processes are made, guaranteeing quality control, eliminating waste, and avoiding the reworking efficiency. Such technological breakthroughs are especially useful in reducing surface roughness when dealing with large scale production where efficiency and consistency are paramount determinants of success.

As environmental regulations are becoming more stringent and customers are beginning to insist on environment friendly products, then sustainable finishing is of great concern. Processes and new formulations are under development in order to minimize their environmental effect without compromising the performance properties.

Quality Control and Testing Methods

An extensive testing and inspection practice is important when it comes to effective quality control of sheet metal finishing as this should guarantee uniform outcome and client satisfaction. Testing can be carried out in form of adhesion testing, corrosion resistance testing, thickness testing and appearance testing.

Uniform methods of testing like ASTM and ISO norms give honest standards of assessing the nature of finishes, and their performance. The standards allow manufactures to specify finish details in a way that helps achieve performance requirements on finished products.

High-tech inspection technologies such as the automated surface inspection systems and non-destructive testing methods are enhancing quality control possibilities, in addition to decreasing time and inspection costs. These are more useful when manufacturing many pieces since it would be impractical to inspect things manually.

Cost Considerations and Economic Factors

The process of sheet metal finishing is very expensive and quite expensive on the basis of process used, complexity of parts being done, quantity of parts being printed, and the quality requirement. When manufacturers are aware of how various types of finishing options are priced up, particularly in addressing surface imperfections they will have an informed choice of determining how their finishing needs are balanced with their budget capabilities metal plating.

The economic aspect of finishing also heavily depends on volume considerations when more processes can produce a better per-unit cost at higher volumes of production. Energy requirements to set-up, efficiency of material usage, and the time required during processing all have a financial role to play in the overall cost make up of finishing operations.

It is as often the case in life-cycle cost analysis where it is found that even more expensive finishes offer greater value in the long run. The critical applications should consider such factors as maintenance, frequency of replacement, performance degradation when selecting a critical application finishing option.

Environmental and Sustainability Aspects

The issues related to the environment in sheet metal finishing include generation of waste, consumption of energy, chemicals involved and the recyclability at the end of its life. The modern finishing processes are becoming more and more environmentally friendly over maintaining or enhancing the performance parameters sheet metal materials0.

Regulatory requirements are also in a state of continuous change as there are more regulations being placed on volatile organic compounds, hazardous air pollutants, and waste disposal conditions. To be consistently compliant with regulatory requirements and prevent possible penalties associated with them, manufacturers should be on the same page with the latest regulatory requirements electrical conductivity.

Some sustainable finishing practices are: optimisation of the process to cut waste, more environmentally friendlier chemistry, and closed-loop systems to effect minimal environmental burden. These habits would be beneficial to the environment and the economy most of the time due to a better performance and the saving of costs in waste disposal both the appearance.

Industry Applications and Case Studies

The requirements of various industries regarding sheet metal finishing are different depending on the conditions under which the industry operates, its performance demands, and different regulations required surface debris. Automotive uses put emphasis on the resistivity of corrosion and physical appearance, whereas medical device usages put emphasis on cleanliness and biocompatibility zinc plating.

The requirement of aerospace applications requires finishes, which can handle the extremes of temperatures, corrosive conditions and very strict weight requirements molten zinc. Such demanding uses can be a source of driving innovation in finishing technology and materials surface grinders.

Processing of foods and pharmaceuticals involves finishes, which are very sanitary in their dimensions as well as making the process simple to clean and maintain. The applications may be outlined as specialized finishing practices, specific to sanitary environment.

Future Trends in Sheet Metal Finishing

The possible future trends in the sphere of sheet metal finishing involve designing intelligent coatings with the self-healing effect, antimicrobial surfaces, and coatings that modifications in the environmental setting visually appealing. These new materials bring potential of enhancing the product performance and functionality glass beads.

The use of automation and robotics in finishing operations is being adopted to achieve consistency in the operations; to cut down on the labor expenses and to enhance the safety of workers. Such technologies prove to be extra useful in dangerous finishing processes or mass production needs.

Certain types of additive manufacturing techniques are in investigation aimed at the application of specialized coatings and surface treatments that would not be possible or very cumbersome by the traditional manufacturing methods. Those technologies can allow new opportunities in surface property customization and advanced coating architectures.

Conclusion

With changing technology, environmental issues and market needs, the area of sheet metal finishing is moving. To achieve success in the realization of effective finishing strategies a deep analysis of available processes, their usability and factors, which impact their choice and application, should be conducted.

Manufacturing is growing more competitive and sophisticated, and sheet metal finishing is an even more important part of product differentiation and optimisation of performance. Those businesses who take their time to study user specific finishing tactics and apply them practically will have a higher chance of satisfying the needs of their customers and prospering in their area of operation.