Meta Description: Learn about the key differences and main distinctions between cnc routers and milling machines, particularly in terms of high accuracy . Understand the accuracy, compatibility of the material and speed at which they can be cut, costs and make the appropriate choice in accordance to your manufacturing project.

Accuracy and efficiency, along with precision machining, is the key in the modern world of manufacturing. CNC routers and milling machines are two of the most multi-purpose computer numerical control (CNC) machines used. The two also operate through the advanced CAD and CAM software, providing accurate cuts but it is upon knowing the difference that one can decide on the right equipment that should serve your needs in the manufacture you are planning to develop.

Understanding CNC Technology Fundamentals

Computer numerical control machines are radically diverse in terms of manufacturing and they work under the provision of advanced software that directs cutting tools with immense accuracy. The machines operate on a subtractive form of manufacturing whereby some material is removed to achieve desired shapes, as opposed to the layering system by the 3D printing technology. Combination of computer-aided design (CAD) and computer-aided manufacturing (CAM) programs offers the same advantages to manufacturers, as long as consistent, high-quality output is required in a variety of applications.

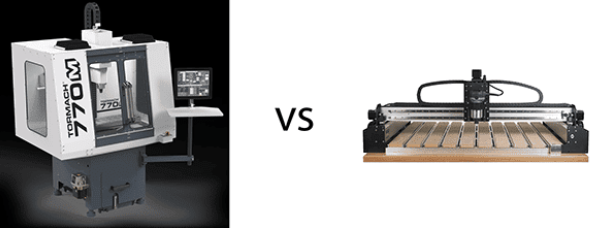

What Is a CNC Milling Machine?

CNC mill machines are rugged precision engineered machineries best suited in heavy duty manufacturing. The machines are very versatile and are ideal to work on tougher materials like aluminum, brass, steel, titanium, and fiberglass. The design of milling machine focuses on precision and can be used to produce high precision components with tolerances of one thousandth of an inch hence it is used to produce intricate and detailed parts.

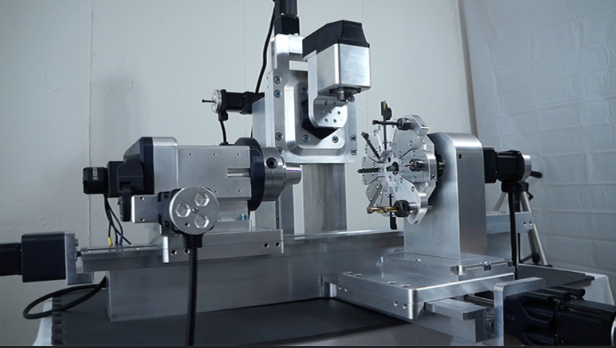

The working arrangement of CNC mills implies that the workpiece is moved and the cutting tools are relatively positioned. Spindle is operated along the Z axis whereas the table is used to move along the X-Y. More than five are used to drive the machine on advanced ones and thus offers more control as well as allows complex geometry which would otherwise have not been possible to machine using conventional machining tools.

What Is a CNC Router?

CNC routers are dedicated machines tuned to machining less hard materials and effectively cut softer materials like wood, foam, plastic, and composites. The machines are also defined by their rotational speed of cutting ability whereby router spindles record a lot higher amount of revolutions per minute (RPM) than the milling machines. This higher rate of rotation however compromises the torque and thus are not recommended when it comes to heavy duty cutting operations.

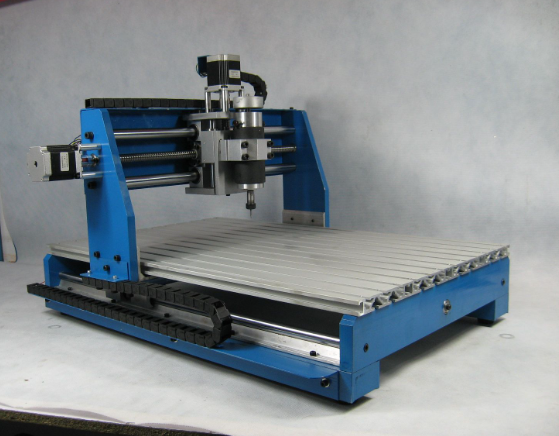

The common machine that is used in CNC routing has a spindle head which moves along the Z, Y, and X axis with the work piece on the table. Most typical models work on three axes but more complex projects might need added flexibility and thus include four to six axes.

Precision and Accuracy Comparison

The CNC milling machines are simply superior to the routers when it comes to precision manufacturing. The high precision level of milling machines renders it the most essential tool in activities where it is required to produce components through precise cutting in tight tolerances: components within the medical devices and aerospace parts. This is achieved through the well built nature and the accurate spindle control hence mills can be used without affecting the consistency despite the heavy cutting operations.

Although not quite as precise as mills, CNC routers are accurate enough to be useful in a wide range of applications in which close precision is not vital. They are also designed more (at least potentially) to filter on speed and efficiency, as opposed to obtaining minimal tolerances, and thus they fit projects where it is acceptable to have some variations.

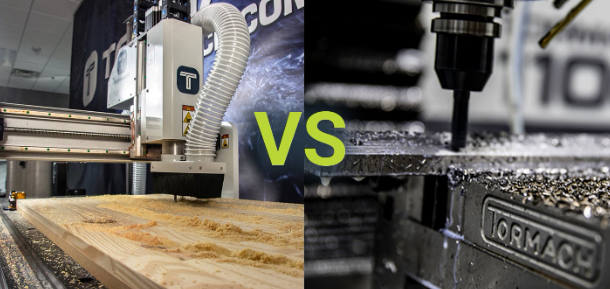

Material Compatibility Analysis

The kind of material to be used is likely to dictate the best type of CNC machine to be used in specific project. CNC measuring machines are good in cutting hard materials because of their structural strength and the high torque that they possess. Such metals as steel, titanium, aluminum and others demand these properties of strength and stability which could be very effectively offered by milling machines.

CNC routers are better suited to work with softer materials where high speed features can be exploited. Composite materials, wood, foam, plastic materials, and thin materials are some of the best fits to processing via router. The routers high RPM, low torque properties make them ideal in obtaining clean cuts in such materials without burning/ melting them.

Cutting Speed and Efficiency Factors

The speed of manufacturing is usually subject to the requirement of quality. CNC routers have far higher cutting speed when compared to cnc machinery and milling machines hence making them suitable when time is an essence and when the end product requires large quantity production of at least simple parts. The high material removal rate may have the capacity to reduce material waste and cut cost of productions drastically to appropriate applications.

CNC mills are less fast and yet they concentrate on precision and quality of the surface finish. When the project needs a vast number of precision parts that are similar, the slow production time of milling processes is usually compensated by the quality that is guaranteed to be very consistent. Speed and precision are two opposite questions that turn into a milestone in the manufacturing planning.

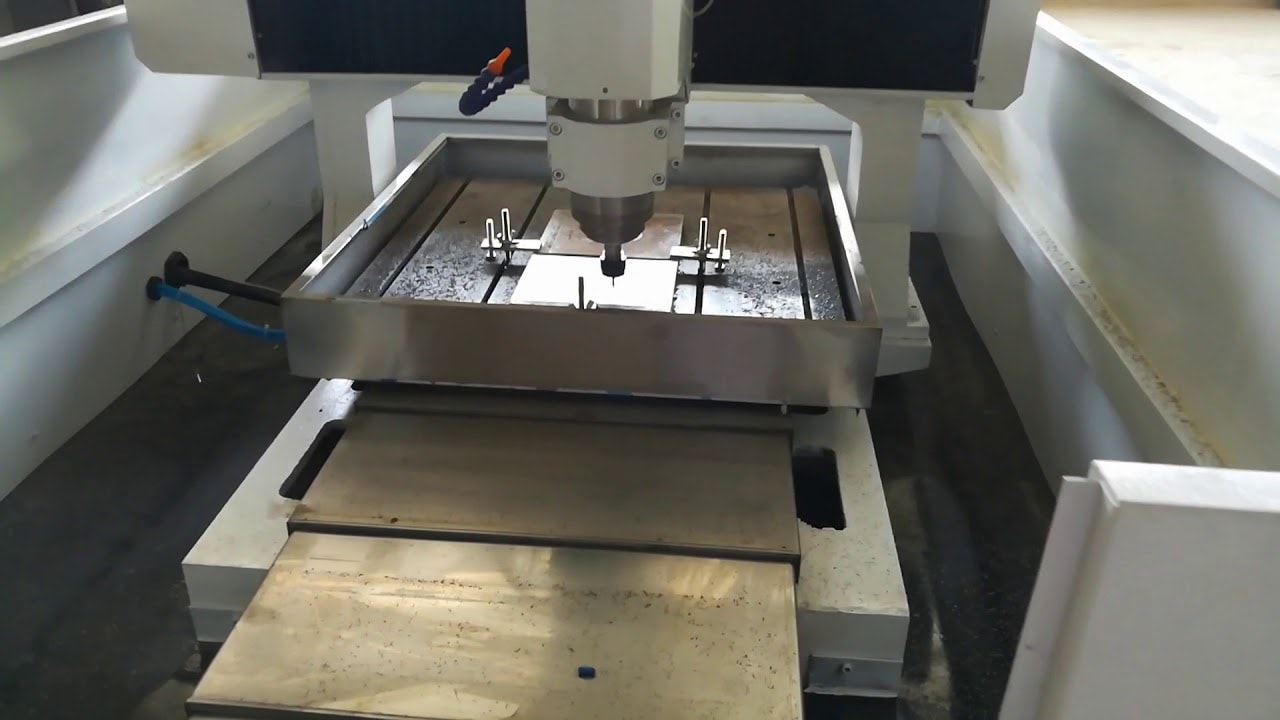

Workspace and Cutting Area Considerations

The physical workspace needs of the two types of machines are so different. The CNC milling machines generally have a higher depth on the Z-axis so that they can cut deeper and deeper workpieces. This is necessary when needing to machine blocks of material or in an attempt to produce parts where there are large depth variations.

CNC routers can typically hold significantly larger X-Y travel distance, and can work with very large work pieces that could not be accommodated by a milling machine table. The increased cutting space is what makes the use of routers in architectural panels, large signs and furniture parts where the size is an initial feature.

Industrial Applications and Use Cases

Various industries should use each type of machine depending on the requirements. Industries that are run by CNC milling machines are aerospace, owning to preciseness and strength of materials where precision and material strength are central to the application, while router machines are often used in less demanding settings . Mills are also essential in those applications where precision is critical because of the possibility to work with exotic metals and carry tight tolerances.

CNC routers have their specialty in woodworking, sign making, architectural millworking, and development of prototypes. Routers are useful in decorative and functional applications of high value where speed of work and flexibility are stressed as well as the ability to process large sheets of material and produce intricate 2D and 3D forms rapidly.

Cost Analysis and Investment Considerations

The initial equipment prices in the CNC routers and milling machines are quite different. In most cases CNC routers are cheaper to enter in, and so are suitable to smaller shops and hobbyists cnc mills operate. But the life cycle cost of owning the machine should include cost of tooling, maintenance and cost of running it over the life time of the machine.

CNC milling machines are more of a long-term investment on average and they are commonly much more appropriate in terms of long-term value in precision manufacturing processes rotary cutting tools. Possibility to effectively work with costly materials and create high-value parts can be a reason to cover this price increase by the better profit value and decrease in wastes end mills.

Maintenance and Operational Requirements

Both types of machines must be maintained regularly to provide a maximum in their performance, yet their requirements are not similar. Due to solid construction and heavy-duty usage, CNC milling machines usually need more significant maintenance operations but can go between maintenance applications. The accuracy parts also require paying much attention to the issue of lubrication and alignment soft metals.

CNC routers are generally faster requiring more regular spindle bearing maintenance and cutting tool maintenance manual machines. Nevertheless, they are often easier to maintain compared to traditional cnc mills other cnc machines , which means routine servicing may be quicker and less demanding to the staff..

Software Integration and Programming

Contemporary CNC units, the routing or the milling, are also endowed with excellent software integration features cnc mill works

. Both of the types of the machines can be smoothly combined with the help of the CAD and CAM software in order to foster the design-to-production process. This can be applied in rapid prototyping, design refinement and easy design processing in batches differences between cnc routers.

Other functions of the software are the real time monitoring, the data analysis and the error detection with a very low possibility of human error occurring in the making of the product injection molding. Programmers are able to program autonomous running of the programs by having the same results even after the production runs rotating spindle.

Safety Considerations and Operator Requirements

Both CNC routers and milling machine have measures that need to be undertaken regarding safety, but the risks involved may be different. Those operating them should be equipped with suitable personal protective equipment especially safety protective gear and hearing gear robust construction. These machines should only be run by well trained personnel conversant with operating procedures and warning signs of malfunction tool paths.

These two types of machines may have hazardous behaviors like burning of materials, over vibration, or travel of the workpieces in case they are not set up properly or maintained intricate shapes. Extraordinary training sessions and the high standards of observation of safety measures play an important role in not only safeguarding operators but also providing uninterrupted production of the desired standards extreme precision.

Quality Control and Consistency Benefits

Among the greatest benefits of CNC technology, the possibility to obtain repeatable results that could not be obtained in other manners should be highlighted. Routers are also used as well as milling machines that offer improved quality control in repetitive and predictable operations that limit the differences in parts.

This uniformity is meant to reflect in lesser defects, wastes, better output and satisfaction of customers material hardness. CNC operations can be predicted meaning that manufacturers are able to deliver quality products within the short delivery periods.

Future Trends and Technology Advances

The CNC sector is advancing with the changing technology. Both routers and milling machines are being transformed by integrating artificial intelligence, better sensor technology and more automation capacity. There is a further promise of these developments to be more precise, efficient, and easier to run.

They have hybrid machines that integrate the functionality of a router and a mill, which they have recently introduced; it provides more flexibility to the manufacturers who require flexibility in their production processes. Also, new technology advances in the spindles and the control system are extending the limits to what can be done in CNC machining.

Choosing the Right Machine for Your Needs

When it comes to choosing between a CNC router and a milling machine, one should pay close attention to his or her needs. Among the aspects that determine the best alternative are the types of materials used, the accuracy level, the quantity to be produced, the available working space and the budget. There are numerous manufacturing operations that have both types of machines in order to take advantage of their strengths.

CNC milling machines are usually the most preferable to use in processes where a lot of precision is needed when using hard materials. Where high speed, large areas of cutting and softer materials are a main factor, this is where cnc routers work best and can tend to give the desired answer.

Conclusion

Your final decision between using CNC routers and milling machines would come down to the given requirements you have in manufacturing, your material requirements and precision requirements. CNC milling operations using machine models are best suited in precision extracts involving hard materials, whereas CNC router models are faster and more efficient in the operations involving softer materials and large workpieces. The knowledge of these fundamental differences will help the manufacturer to make adequate decisions that streamline their production capacities and returns on their investments.