The modern machining of metals using CNC machines has transformed the production industry offering a solution to manufacturing high precision metal parts that are out of this world in terms of accuracy, repeatability, and efficiency. CNC machining can be utilized in a variety of applications, anything as easy as the aerospace parts up to medical supplies.

What is CNC Metal Machining?

CNC or computer numerical control machining is a common manufacturing process taking shape out of a stock of metal materials or plastic using the help of automated high-speed cutting tools. It is a highly advanced method of manufacturing that cuts material in a piecework to define exact pieces based on digital descriptions.

Understanding CNC Machining Technology

Computer Numerical Control Systems

CNC systems are run on mathematical coordinates and computing capacities which gives them amazing precision. The technology employs use of Cartesian coordinates in further dimensions, which are automated by computer control of varieties of cutting tools in drilling boring, removing material milling and other metal shaping activities.

Digital Manufacturing Integration

Contemporary milling machines blend well with CAD (computer-aided design) models which enables engineers and designers to replicate computer models to real parts with excellent accuracy.

Types of CNC Metal Machining Services

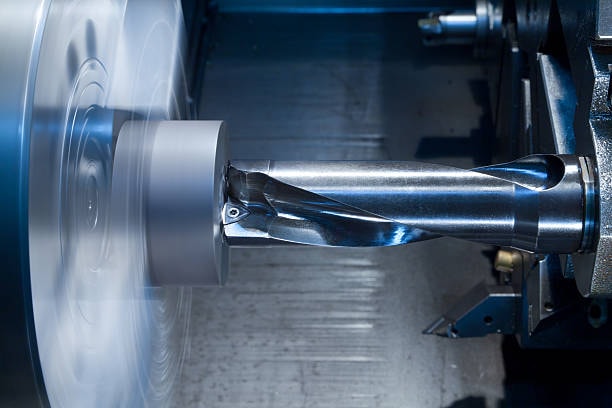

CNC Milling Services

CNC milling processes the cutting tools which rotate at the stationary workpieces to remove them. It is achieved using this process to make custom parts, cnc metal parts with complex geometries, slots, holes, and contoured surfaces at an extraordinary level of accuracy.

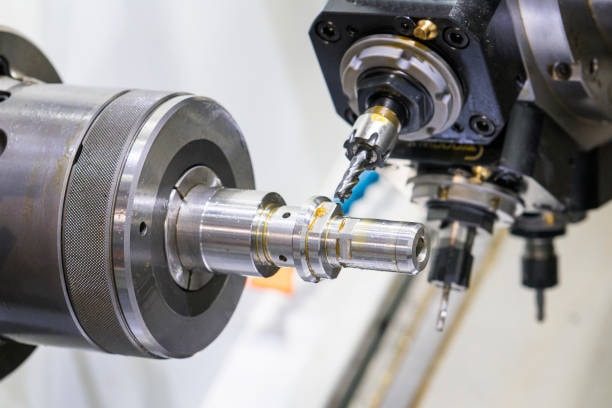

CNC Turning Operations

In CNC turning the workpiece is rotated with the material being shaped by cutting tools, and is mostly used in the production of cylindrical parts, shafts, and parts of rotational symmetry that may require chemical resistance .

CNC Routing Applications

The CNC routing process employs rapid rotating tools to cut materials; it is suitable to produce the various patterns, profiles, complex 2D and 3D shapes in metal stock.

Multi-Axis Machining Capabilities

High-tech CNC machineries are 3-axis, 4-axis, 5-axis to enable production of more complex and intricate shapes with minimum set up adjustments.

CNC Metal Machining Materials

Aluminum Alloys for CNC Machining

Aluminum is also one of the most common materials used in a CNC machine since it has the excellent machinability, its corrosion resistance and strength-to-weight ratio. Ordinary aluminum alloys are:

- Aluminum 6061: Structural general-purpose Aluminum 6061 Aluminum 6061

- Aluminum 5052: Marine and building usage

- Aerospace and high strength Aluminum 2024

- Aluminum 7075 Ultra-high strength aerospace parts

Stainless Steel Machining

The stainless steel due to its high levels of resistance to corrosion and mechanical properties would be most suitable in any production parts for medical application, food processing and also marine application. Well known grades are 303, 316/316L, and 17-4 PH stainless steel.

Carbon Steel and Tool Steel

Carbon steels contain a great strength with high durability to be used in structural applications and tool steels contain great hardness to be used in cutting tools and dies.

Exotic Metal Machining

Exotic metals commonly used with advanced applications include:

- Aerospace/Medical implant titanium alloys

- High-temperature Inconel Inconel Inconel Inconel High temperature

- Chemical processing equipment of Hastelloy

Copper and Brass Alloys

Alloys of copper give good rates of electrical conductivity and resistance to corrosion, and brass is machinable to give fine decorative/functional parts.

Precision and Tolerances in CNC Machining

Standard Machining Tolerances

The tolerances to be maintained on metals shall be +/- 0.005 ” (+/- 0.127 mm) in line with ISO 2768 unless specified. These tolerances are used to provide similar quality throughout productions.

Tight Tolerance Capabilities

CNC machining can work extremely close tolerances as tight as +/- 0.001″ in producing precision machined parts , which is done via highly advanced machine tools, a quality management system environmental and measurement systems.

Geometric Dimensioning and Tolerancing (GD&T)

CNC machining nowadays has adopted the use of GD&T principles to ascertain fit, form and functionality of machined parts in the context of assembly.

CNC Machining Processes and Techniques

Subtractive Manufacturing Principles

The CNC machining uses principles of subtractive manufacturing with use of solid stock materials to be machined away in pursuit of final component geometry. This method retains the original mechanical properties in the material.

Tool Selection and Optimization

Use of a correctly selected tool plays a large role in the efficiency, surface finish and accuracy of the machining job. These are such things as material compatibility, cutting speeds, and geometrical requirements.

Workholding and Fixturing

An efficient workholding dictates that the part is steady when being machined to achieve the desired shape and it is also accessible to cutting tools and gauging equipment.

Programming and Setup

Toolpaths are generated by skilled programmers and machinists by using CAD model and tailor cutting parameters to highlight cnc machining advantages make them efficient and quality.

Surface Finishes and Post-Processing

As-Machined Finishes

The standard as-machined finishes offer useful surfaces to be used in most applications and usually meet 125 Ra surface roughness and above.

Mechanical Finishing Options

Other mechanical forms of finishing are bead blasting to produce uniform matte finishing and result in turning whole parts into tumbling to remove dents and round edges.

Chemical Treatments

Passivation and stainless steel enhance the corrosion resistance and handling requirements are achieved with chemical treatment of surfaces providing conductive aluminum surfaces.

Coating Applications

Higher finishes are available: the anodizing of aluminum, the powder coating to be durable for precision machined components , and the plating to improve their electrical properties or indeed their beauty.

Quality Control and Inspection

Dimensional Inspection

Accuracy measuring instruments such as coordinate measurement machine (CMMs) are used to check against dimensional and geometrical tolerances during the manufacturing process.

Material Certification

Certification results in traceability and industry standards in which, especially aerospace and medical applications are important.

Statistical Process Control

Contemporary CNC shops adopt the methods of statistical process control so as to keep quality consistent and spot obstacles before they affect manufacturing.

Industries Served by CNC Metal Machining

Aerospace Applications

Aerospace industry can not be possible without CNC machining of the components involved in it that demand ultimate level of precision, low weight and certified materials.

Medical Device Manufacturing

CNC machining is used by medical device manufacturers to produce such plastic parts as surgical tools, implants and diagnostic equipment made of biocompatible materials that must meet high standards of quality.

Automotive Component Production

Example of automotive application consist of the use of automobiles on an engine-part or on a transmission-part, which demand a high volume production capacity at high quality levels.

Electronics and Telecommunications

Electronic applications require precision housings, heat sinks and RF components that provide close tolerances and special materials.

Defense and Military Applications

The defense contractors need CNC machining of weapons system, vehicles, and special equipment that comply with military specifications.

Rapid Prototyping with CNC Machining

Fast Turnaround Capabilities

Contemporary options in CNC machining services involve prototyping being done at a fast pace of about 24-48 hours within which simple components are fabricated.

Material Flexibility

The variety of materials used in prototype machining works in the favor of the engineering since they can easily carry out tests using the actual production materials.

Design Iteration Support

The high rate of design iteration that is offered by CNC machining also allows engineers to incorporate and make changes in designs quickly as a result of physical testing.

High-Volume Production Machining

Scalability Considerations

CNC has a good range of economical scale from single prototypes up to thousands of production piece, that is limited by the complexity of the particular part and its set up requirements.

Cost Optimization Strategies

Processes with high volumes have streamlined setups and optimized tooling and automatic material handling processes to drive down the unit cost.

Automation Integration

High end CNC plants incorporate robotic stock management and robotic examination systems to optimize productivity and repeatability.

Design for Manufacturability (DFM)

Machining-Friendly Design Principles

The good DFM design will take into account the availability of tools, material removal rates and fixturing needs in the design process so as to optimize manufacturing.

Feature Guidelines

The design guidelines prescribe proper corner radii, wall thickness and the size of holes so as to carry out efficient machining process.

Cost Reduction Strategies

There are undoubtedly smart design decisions, which can greatly improve the cost of machining by reducing the amount of setup changes, decreasing the cycle time and optimize the use of material.

Choosing the Right CNC Machining Partner

Capability Assessment

In considering a possible machining partner, it is important to consider material and machining equipment capabilities, quality systems and technical expertise concerning your requirements.

Certification Requirements

Regulations can be met through industry-specific standards (e.g. AS9100 is an aerospace-specific standard, whereas ISO 13485 is a medical device standard).

Geographic Considerations

There are also conditions due to location of the partner that can influence shipping costs, lead time of delivery and also the effectiveness of communication between businesses.

International Logistics and CNC Machining

Global Supply Chain Integration

The global approach to modern manufacturing frequently implies cooperation with the suppliers in other countries, so the complex marketing of logistics is necessary to guarantee the date of supply and economical sources of its manufacturing.

Customs and Compliance

Exports of machined parts also require different customs regulations and classifications of duty and documentation standards that should be followed.

Cost Factors in CNC Metal Machining

Material Costs

Cost of raw materials, particularly for each type of metal alloy, differs greatly depending on the type of alloy, market conditions and needed certification, and is a huge percentage of the total cost of a project.

Setup and Programming Costs

Programming time, choosing of tools and workholding arrangement are the initial costs required to run a set-up, hence lot size is a significant aspect regarding economy.

Machining Time Variables

The cycle time is affected by the material removal rates and whether the surfaces are required to be finish and the complexity of the geometries, which in turn directly affect the per-unit costs.

Secondary Operations

Other processes like heat treatment, finishing and inspection increase the costs of the total projects but might be required in case of given applications.

Technology Trends in CNC Machining

Advanced Tool Materials

Cutting tool technology, including electrical discharge machining, is also progressing in new coatings, substrates and geometries to enhance productivity and quality of parts cnc machining cost.

Smart Manufacturing Integration

Industry 4.0 concepts incorporate sensors, data analysis, and machine learning in order to optimize machining operation, and anticipate maintenance requirements.

Automation Advances

Automated material handling and robotic integration minimize the labor cost of material handling and increase consistency and throughput injection molding.

Environmental Considerations

Sustainable Machining Practices

Environmental accountability involves management of coolants, recycling of chips and energy-saver machining plans metal cutting.

Material Waste Reduction

The most efficient programming and nesting policies assure waste material but also a high level of efficiency in production custom machined parts.

Coolant and Lubricant Management

Effective management of coolant creates compliance to the environment as well as taking into consideration performance and lifespan of machining and tools metal workpiece.

Troubleshooting Common CNC Machining Issues

Tolerance Problems

The tolerances may be affected by the thermal effects, wear of the tools or compliance of the machine, which must be investigated in a methodical way and made right sheet metal parts.

Surface Finish Concerns

Desirable surface finishes can be poor due to the poor cutting parameter, tool wear, or vibration problem that need to be optimized in the process.

Tool Life Optimization

Tool life can be maximized by balancing between cutting parameters, coolant use and material characteristics to obtain the best outcome cnc parts.

Future of CNC Metal Machining

Emerging Technologies

Developments in technologies such as additive-subtractive hybrid machines and new material processing allow CNC machining operation to be extended traditional machining.

Market Growth Projections

The worldwide CNC machining industry is now expanding because of the need of the aerospace, auto, and medical devices to have precision parts.

Skills Development Needs

The development of the industry demands that workforce development in terms of programming, setup, and quality control are still needed as the demand over the years has grown subtractive manufacturing process.

Conclusion

CNC metal machining is at the center of modern manufacturing and the technology has produced precision, repeatability and material flexibility that is essential in the modern application milling operations. Whether it is aerospace parts that must be machined with an unusual precision or medical equipment whose materials must be super-biocompatible, CNC machining keeps developing to suit the needs of the industry.

To achieve success in the implementation of CNC machining projects, one should pay much attention to the choice of materials used, the organization of processes, and collaboration with relevant service providers. Due to the fast pace of technology development and the involvement of more intricate global supply chains, deployment of professional logistics services is necessary in case of manufacturers running across international markets.

CNC metal machining will have a great future ahead as, due to technological growth, integration of automation in work, and increasing application scope, industrial revolution and growth is bound to happen.