Get in-depth CNC machining cost benchmarks, entry-level desktop CNCs ($150) to high production industrial CNCs ($500K+), including special tooling considerations . Gain knowledge on pricing factors, hidden costs, and cost- cutting measures of your manufacturing requirements.

A CNC (Computer Numerical Control) machining world is a world of awesome manufacturing precision and flexibility, yet the costs are not always intuitive to anyone due to the many factors involved . If you are a small company owner thinking about buying your first CNC machine or an already self-established manufacturer that wants to broaden your manufacturing capabilities, this extensive guide will lead you to the intricate world of CNC machining prices by considering all the factors involved .

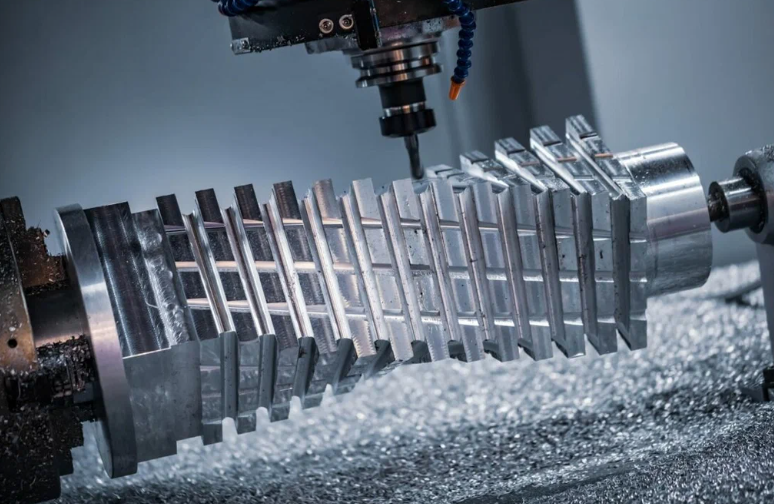

Understanding CNC Machining Technology cnc milling machines

CNC machining is an innovative solution to manufacturing by employing computer controlled machine tools to make very accurate cnc machined parts and components through a detailed cnc machining process . These are programmatic machines, which cut, drill, mill and shape materials in brilliant precision. With the growing decades, technology has undergone significant changes enabling it to be accessible to small and large businesses and through this advancement and the variety of applications possible to industrial complexes, the accuracy has not been impaired.

Types of CNC Machines and Their Applications

The machine market of CNC provides the market with a number of technologies that are applicable in the manufacture process. CNC laser cutters possess very powerful laser beams which can amazingly cut materials like metals, wood and plastics, making them ideal for custom parts . Waterjet cutters use high-velocity droplets of water together with abrasive materials in order to make cuts in hard to cut materials such as carbon fiber and ceramics. CNC routers use spinning cutting tools to cut forms in composites, acrylics and wood and milling machines are ideal in making intricate three-dimensional shapes.

Entry-Level CNC Machine Costs or cost of cnc

Desktop CNC routers are available in the market between 150 and 500 dollars and they suit CNC total beginners. They are small machines that are ideal with hobbyists and small projects involving raw material, and they are easy to use with simplicity compared to industry machinery. They are fairly capable though primitive, which constitutes a perfect inroad into the world of CNC, and basic cutting and engraving works on most materials can easily be done with them, making them a cost effective option .

Hobby-Level CNC Equipment Pricing

With a step up of the entry-level, hobby-level CNC machinery is priced between $1,000 and 5,000. This type covers more durable CNC routers, CO2 lasers and small plasma tables. The accuracy of these machines is higher and they have increased working space as well as other features when compared to desktop models. They are perfect with serious hobbyists, small shop owners and start-ups that hope to open small raw manufacturing businesses, especially when considering larger production volumes .

Professional CNC Machine Investment

CNC machines are professional equipment, and a machine that will cost around 50,000 to 100,000 dollars is just a sizable investment, which also incurs ongoing maintenance costs . They have entry level 3-axis mills and professional CNC routers that can perform production tasks. There is the higher cost which indicates the better build quality, greater precision, more developed systems of controls and the possibility to work with a wider palette of raw material regularly.

Industrial CNC System Costs

CNC systems used in the industrial sector are sold above average market price with a range of between 100000-500000 dollars. Those include industrial fiber lasers, production-quality milling machines and high-definition plasma tables, all of which can significantly impact labor costs . These machines are very fast, accurate and reliable required in mass production processes. It is a huge cost, yet the productivity may be worth the budget.

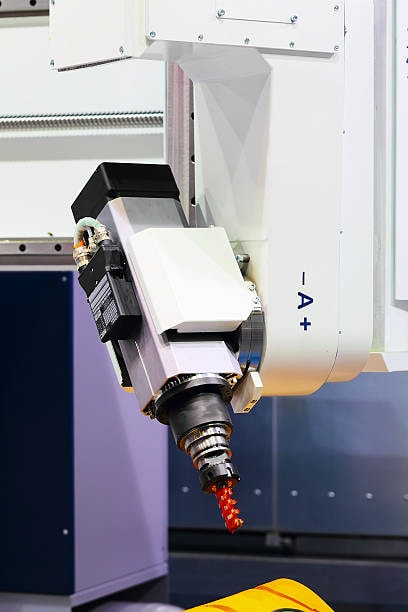

Advanced Multi-Axis Machine Pricing

These most advanced models of CNC machines, especially the 5-axes milling machine are easily over half a million US dollars. The high-tech machines offer unmatched ability to undertake complex part production, aerospace parts and medical equipment. The reason it is high in cost is due to the complexity of engineering, powers of precision and specialized parts required to accomplish multi-axis capabilities.

Machine Size Impact on Pricing

Size also plays a critical role in the sale of CNC machines where higher prices are charged on a larger machine since they consume more material, involve more complicated designs, and have more advanced structure. The price of a small desktop laser cutter is extremely low compared to that of a 12kW industrial laser device. Depending on what you would like to use it, its size requirement can vary, thus it is always imperative to give a lot of thought when it comes to the size of the parts in your budget planning.

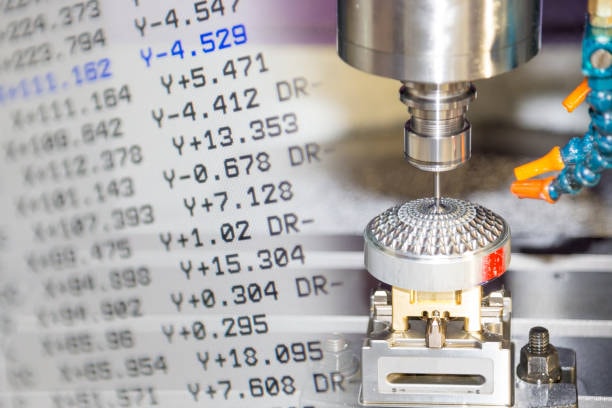

Precision and Accuracy Cost Factors

The cost of CNC machines is drastically affected by the need of precision. Hobby machines may reach tolerances of +0.010 “- 0.010 inches which can perform a variety of applications. But to attain tight tolerances of measurements of +0.0003 inches and less will entail much more costly systems. Every increment of precision can translate into thousands to hundreds of thousands of dollars to the machine price; among the main factors, a major factor is the need to align precision needs to genuine needs.

Speed and Productivity Considerations

Cost and future productivity are influenced by the speed of machine. High speed CNC machines use more powerful motors, unique pieces as well as strong control systems making them more expensive to buy. The more profitable use of faster machines however tends to have a higher payback in productivity, sometimes even exceeding the higher upfront cost with a higher throughput and a shorter unit turn manufacturing process, leading to reduced machining time more machining time .

Material Compatibility and Versatility

The CNC machines that can process various materials are expensive compared to the specialized systems. Metals, plastic, composites and wood have a variety of machines that involve the use of different cutting tools, power systems and safety. Although versatile machines are flexible, they might not perform best in any one area, such as surface finishing and often a significant portion of the performance depends on how well they meet specific requirements.

Brand Reputation and Quality Premiums

Well known producers with reputable products usually have higher prices of their CNC machines. Some brands such as Haas, Mazak, and DMG Mori are more reliable, have better support and resale that makes them worth more when purchasing several factors. Alternative brands that are not major may present cheaper prices but may be deficient in their supporting networks, documentation, or the sustainability over a long period of time.

Software and Control System Costs

The technologies of CNC machines have advanced that needs a sophisticated software and control system, which increases the total cost. They may require thousands of dollars per year license fees on professional CAM software as well as substantial value and cost in the form of advanced control systems such Fanuc or Mitsubishi. Take into consideration costs of total system, which include software compatibility and usability, maintenance, and support, as well as any additional costs that might arise more axes .

Tooling and Accessory Expenses

Apart from the machine itself, CNC operations also need different tools and accessories. Cutting tools, work holding tools, measuring instruments and maintenance materials are recurring costs intricate parts. Full tooling package of a professional CNC mill may go beyond 10-50 000 dollars depending on applications and material being machined deep cavities.

Installation and Setup Costs

Any professional CNC machine installation requires electrical work, the preparation of foundation and commissioning of the system. Costs of installation are highly dependent upon complexity of the machine and the needs of the facility in question and can cost several thousands to tens of thousands of dollars. Performance and safety on machine depend on proper installation.

Training and Operator Costs

There are operational costs of CNC machines which need skilled workers. There are training programs, certification training, and competitive pay that CNC operators attract, which increases cost of operations thin walls. Examine the availability of capable operators in the region which you propose to operate in, especially in relation to manual processes, and consider training expenses in your overall calculation of cost part material.

Maintenance and Service Expenses

CNC machine performance and long life CNC machine requires regular maintenance. This kind of maintenance usually varies between 5 and 15 percent of the cost of the machine. this consists of: preventive maintenance, replacement parts, and emergency repair. Such costs can be forecasted and managed through the establishment of maintenance contracts with the competent service providers most manufacturers.

Hidden Costs in CNC Ownership

There are numerous non-obvious expenses in the overall costs of CNC owning. Power consumption, facility adjustments, insurance, and safety abidance may increase costs of utility, especially for many machines operating simultaneously. Have in mind these factors in calculating the actual costs, returns on investment, and operational budgets.

Used CNC Machine Market

Used CNC machines market provides the potential of great cost reduction especially to machines which were $10,000 and above during original purchase. The savings may be thousands or hundreds of thousands of dollars with prices of new machines hourly rate

. Nevertheless, purchases ofptions of used machines demand thorough observation and analysis of maintenance records and the remaining amount of useful life.

Financing Options for CNC Equipment

Many other financing programs enable companies to purchase CNC equipment without any huge outlay. There are equipment financing loans, leases and rent to own programs with flexibility to accommodate varied financial lower cost. When considering financing options, taking into consideration interest rates, terms and implication of taxation is always advisable production time.

Outsourcing vs. In-House Production

To most companies, it is economically beneficial to have a third party carry out CNC machining than buying their own machines. By outsourcing, one is done with capital investment, maintenance and staffing and access to new age equipments and expertise may be availed. When deciding on this option, evaluate the volumes of production, complexity of parts and timing requirement to effectively reduce costs .

Cost-Saving Strategies

CNC machining costs may be avoided by a few measures. Redesigning of parts so they are readily manufactured, concentration of orders done, use of proper material, and proper maintenance of tools all help in cutting costs, as well as understanding the factors that affect CNC machining expense . Partnership with established suppliers and constant upgrading of processes, while adhering to design specifications, are other ways of curbing costs.

Return on Investment Analysis

The ROI calculations of the CNC machine should be taken very seriously by examining all expenses and advantages. Battle it out between purchase price, installation, training, maintenance and operational cost and compare it with the money that could be saved or new capacity and profit making potential manual labor. A majority of the successful CNC investments yield positive ROI within a period of 2-4 years based on the fact that the efficiency and a new business opportunity have been created.

Conclusion

The price of CNC machining is extremely different depending on the kind of machine, machining, and planned uses. The investment in terms of cost ranges between low end, industry-grade desktop systems at 150 dollars to large, complex industrial systems over half-a-million dollars, particularly in cnc milling machines, and the systems are needed to match the production needs and business necessities cnc machining projects. This success is attributed by taking into consideration the overall cost factors; the hidden costs as well as the operational costs cnc machining center.