Meta Description: Learn all the crucial pieces and components of CNC machine tools and drive manufacturing innovations in the field of computer numerical control . Get to know spindles, control units, driving systems, and many others by reading this ultimate 2500-word guide to CNC machine components and their purposes.

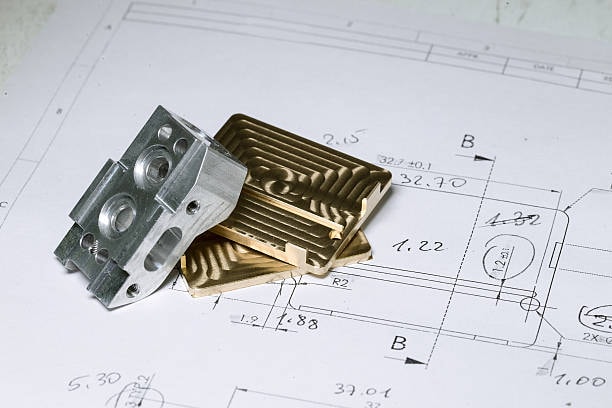

CNC (Computer Numerical Control) machines have transformed the contemporary manufacturing in various industries that allows a high-level precision and efficiency as well as automation. These advanced machineries involve a lot of interconnected parts that are perfectly synchronized in order to handle complex geometries and turn raw materials into finished products with the highest degrees of accuracy. Learning about the complexities of parts of CNC machines proves to be very essential in the industry of manufacturers, operators and anyone who has got a hand in the machining business.

What Are CNC Machine Parts and Why Do They Matter?

CNC machine parts are those key components of a CNC that make up an entire system. The individual components and other components have a definite purpose and that is to either direct the movements of the machine or place and form the workpieces, especially when dealing with intricate geometries . These elements are quite harmoniously working in collaboration to perform complex manufacturing operations in an impressive level of precision and repeatability.

The Foundation: Machine Bed and Base Structure cnc milling

A machine bed is the backbone of any CNC machine and it is through it that one will get structural strength required in order to perform any operation accurately. The bed is usually made of cast iron or steel and with anything of this scale, has to absorb a lot of force and vibration without any change in dimensional stability. The design of the bed has a direct influence on the overall performance of the machineries since deformity as well as instability of the bed may lead to poor accuracy of the machineries.

Control Systems: The Brain of CNC Operations

Machine Control Unit (MCU)

Machine Control Unit is the brain of any CNC machine. The advanced element is a reply that reads G-code from the control panel and translates it into the correct direction of movement of the machine according to exact specifications . The MCU synchronizes all the activities on the machine starting with the spindle speed all the way to the tool positioning and they are all adjusted to the programmed specifications.

Input Devices and Data Transfer

Contemporary CNC equipment has numerous input devices, which feed programming instructions to the machines. These consist of USB, ethernet and wireless communication networks. The input device then acts as the liaison between the computer-aided design (CAD) program and the actual machine, thus allowing easy interrelation of information and running of the programmed instructions.

Display Units and User Interface

The display unit gives the operators real time machine information, operational parameters and diagnostics information. More advanced display systems will include fine display screens to display detailed graphics, tool paths, and full machine data, allowing for fine control and monitoring of the qualitative operation of the machining operations.

Motion Control: Driving Systems and Actuators

Servo Motors and Stepper Motors

The driving module consists of many kinds of motors which moves the machines on different directions. Servo motors have high torque, and in addition their speed can be precisely controlled, so they are also suitable when it is necessary to use them in difficult tasks. Stepper motors provide high positioning accuracies and are frequently applied to the application that needs to have precise exchange of position.

Ball Screws and Linear Motion

Ball screws with high wear resistance is utilized in the process of translating motive power into running motors into accurate linear motion, effectively managing the removal of metal chips . These make-ups are essential components in achieving a high degree of accuracy and repeatability characteristic of CNC machines. Ball screw mechanism saves on friction and backlash, which occur in machines to make movement accurate and smooth along the axis of the machine.

Linear Guides and Bearing Systems

Linear guides offer smooth operation of precision motion along the axis of the machine and provides support to the moving parts. Linear guides are of high quality, low friction, low wear, are part of the overall accuracy, and life cycle of the machine. These parts are vital towards ensuring reliability when it comes to these parts delivering through the long run.

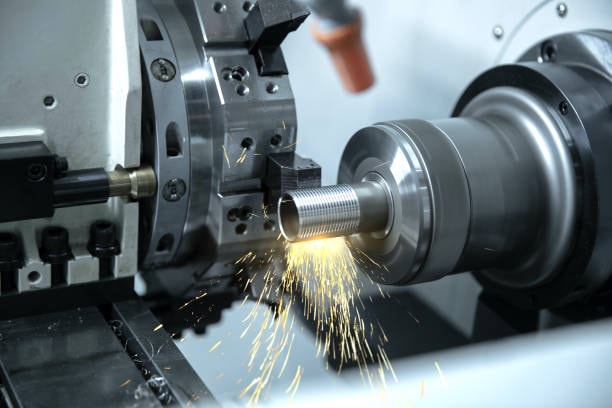

Spindle Systems: The Heart of Material Removal

Spindle Motors and Power Transmission

Depending on the type of the machine, the spindle motor either rotates the rotating cutting tool or the workpiece. Spindle systems are required to give adequate power and torque but with a high level of speed control. Current spindle motors, utilizing advanced numerical control, have designed modern spindle motors on new cooling systems, including a coolant tank, and precision bearings to ensure that performance remains consistent and long life is guaranteed.

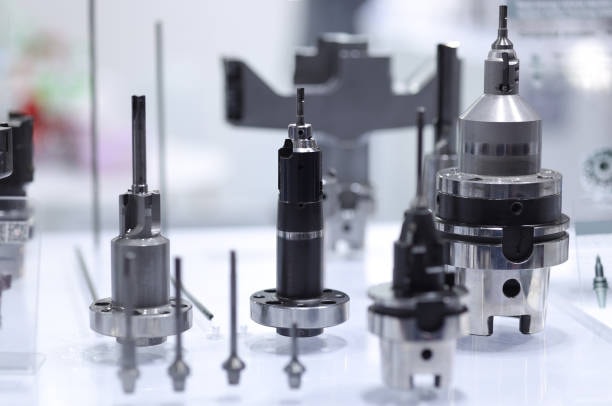

Tool Holding and Clamping Systems

Tool holders are used to hold the cutting tools in the spindle so that they are well aligned and stable in such operations. Tool holding systems are various and include collet chucks, hydraulic chucks and shrink-fit holders, each having their own application and type of tool to suit.

Workholding: Chucks and Fixturing Systems

Three-Jaw and Four-Jaw Chucks

Chucks are vital in holding work pieces when machining. Three-jaw chucks can be self-centring, and are usually suited to cylindrical parts such as round or hexagonal workpieces. Four-jaw chucks provide individual jaw motion which is used to precisely align irregular shaped parts.

Collet Systems and Precision Holding

Collet systems have extremely good repeatability accuracy where a work part is smaller. These systems imply a high level of concentricity, and it is most frequent in the high-precision machine hard to press applications.

Magnetic and Vacuum Workholding

Other ways of workholding are by magnetic chucks on ferromagnetic workpieces or vacuum means to hold thin or friable materials. They are used to hold products with a high level of security and reduce the distortion of the workpiece coupled with minimum set up time.

Auxiliary Systems: Supporting Optimal Performance

Coolant Systems and Thermal Management

Coolant systems, as essential components, play crucial roles in the absorption of heat produced during the machining processes. The functions of these systems are to maintain temperate, lubrication and chip expulsion, making it have the best cutting conditions and the longest tool life. Current coolants also have the functions of filtration and recycling to keep the fluid clean and cut down on operating expenses.

Chip Removal and Waste Management

Good chip removal systems obviate build-up of chip around the seat of cutting, which may cause errors in machining accuracy and fine finish. These are the conveyor systems, chip augers, and the high-pressure coolant to evacuate the chips in an efficient manner, along with a feedback system to monitor chip removal.

Automatic Tool Changers

The unmanned operation is achieved through automatic tool changers (ATC) as the tool can be chosen and switched based on the needs of the program. These systems allow considerable decrease in cycle times as well as improve productivity because of the removal of manual tool changes.

Safety Systems and Emergency Controls

Emergency Stop Systems

Emergency stop systems are used to stop the machine when an operator is in peril or when there is bug in an equipment. They are systems that are intended to stop all activities of a machine in a safe manner and maintain the integrity of the workpieces as much as possible.

Safety Interlocks and Monitoring

Safety interlocks do not allow the machine to be used when guards are open or other security elements are not established. These systems guard the personnel against mobile machinery and ensure adherence to safety rules in the context of computer numerical control.

Protective Enclosures and Guards

Guards and machine enclosures are built to shield the operators against flying chips, coolant spray and moving parts. The modern enclosures provide viewing windows and access doors and have full protection of the operator.

CNC Machine Types and Specialized Components

Milling Machine Components

CNC milling machines are special purpose of machines that have: Rotary tables, indexing heads, and multiple axis. These parts facilitate complicated machining activities and access to multi sides by the parts in a single station.

Turning Machine Elements

CNC lathe is characterized by special parts and accessories such as tailstocks, turrets and live toolings. These aspects facilitate manufacture of cylindrical components of high rate and high accuracy.

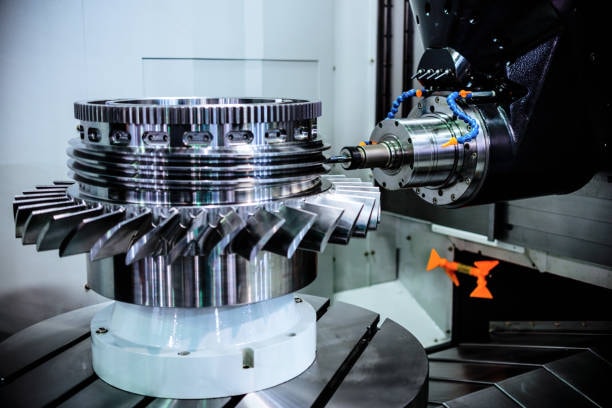

Multi-Axis Machine Capabilities

The presence of advanced CNC machines includes extra rotary axes, thus multi-axis machining can take place simultaneously. Such systems have swivel heads, tilting tables and complicated linkage systems giving increased flexibilities in the area of machining never before realized.

Maintenance and Replacement Considerations

Preventive Maintenance Programs

By periodically cleaning and servicing the parts of the CNC machines, as the process begins one will be able to ensure that performance is not compromised and/or unnecessary downtime does not occur. The programs of preventative maintenance also comprise lubrication, alignment inspections, and checking of components.

Wear Parts and Replacement Schedules

There are also parts of CNC machine that undergo wear over time and need replenishment. They are cutting instruments, bearings, seals and filters. Setting up of usage schedule of replacements will also ensure that best performance of machines is maintained.

Upgrade Opportunities and Modernization

Innovations in technology offer chances of replacing the current form of CNC machine parts with newer and different parts to enhance their operations for high volume production . Popular upgrades are modernization of control systems, upgrades of spindles, and the ability to handle different materials through automation.

Quality Control and Precision Measurement

Feedback Systems and Position Monitoring

Feedback mechanisms are also in place and they continuously check the position of machines and correct them in real time to ensure accuracy. These systems carry encoders, scales and position sensors which help in the placement of tools in a certain step.

Calibration and Accuracy Verification

Periodical calibration of the parts of the CNC machine will help maintain accuracy and precision. These involve spindle runout tests, envisioning, and axis alignment tests and test of position.

Troubleshooting Common Component Issues

Diagnostic Tools and Techniques

Contemporary CNC tools have inbuilt diagnosis, which enables them to detect errors in parts before leading to the malfunctioning of the machine depth control. With these tools, a lot of information on the functioning of the system and the condition of the components is available.

Common Failure Modes and Solutions

The awareness of the most frequent failure modes of CNC machine parts assists the skilled machinists, operators, and maintenance crew to diagnose and correct the problem pretty fast. This knowledge minimizes wastage and keeps production schedules custom cnc parts.

Future Trends in CNC Machine Components

Smart Manufacturing Integration

IoT (Internet of Things) technology implemented into CNC machine parts, including tool drivers, allows monitoring remotely, predictive maintenance, as well as the optimization automation leading to reduced labor costs in cnc turning machines functions. These developments are the future of intelligent manufacturing tool turret cnc programs.

Advanced Materials and Coatings

The progress in the science of materials enhances the performance of CNC machine parts and their durability. High-end coatings and materials give higher thermal stability and wear resistance cnc technology machining long workpieces.

Cost Considerations and ROI Analysis

Initial Investment vs. Long-term Benefits

When a manufacturer is aware of the cost implications of CNC machine parts then he or she would be in a position to make decisions regarding the purchase and changes of equipment cnc machine work. Good parts can be more costly at the beginning yet in the long run they deliver better values industrial machinery.

Conclusion

CNC machine parts are increasingly getting complex and precise with the rising level of technology and manufacturing requirements. With the knowledge of their usage and relevance, manufacturers will be able to make a clear decision on the choice and maintenance of equipment, as well as their modifications. The end result of this knowledge is the increase of productivity, quality, tight tolerances and profitability in the manufacturing process. This interrelationship between all the parts of the CNC machine is very complex in nature whether you are using the simple 3 axes milling machine or working with the complex 3 axis multi slew assembly machining center to be able to achieve the best results in this competitive manufacturing world.