When it comes to manufacturing precision parts the choice of machining equipment must match the needs of the project. CNC lathes and CNC mills, which are essential machine tools, belong to the class of the most basic equipment in the modern manufacturing industry and have their unique features and opportunities. Learning how to differentiate amongst these machines is vital among manufacturers, engineers as well as companies all bent on streamlining their manufacturing operations and getting better outputs.

CNC lathes and CNC mills employ computer numerically controlled technologies in modelling accurate parts out of raw materials in a subtractive manufacturing process. Nevertheless, they have different operational processes, fields of practice, and the primary difference lies in best use scenarios. It is an elaborate guide on how to determine whether to use CNC lathe or CNC mill whenever undertaking manufacturing projects.

What is CNC Machining and How Does It Work?

CNC machining describes a new way of manufacturing and revolutionized the traditional process of metal working. The CNC is an abbreviation of Computer Numerical Control and this implies that the lathe and mills utilise computer-based hardware to precisely cut and manufacture accurate shapes. The technology allows manufacturers to create sophisticated components of a high accuracy and repeatability level, utilizing a stationary cutting tool .

The most basic concept of CNC machining is that of subtractive production where material is carefully removed out of a solid workpiece to form the required shape. The process is an extreme contrast to additive manufacturing processes such as 3D printing, which constructs parts using layering. The CNC machines contain programming commands that enable them to control their cutting tools and feed rates, spindle speeds and tool paths with tight tolerances impossible to the human eye.

CNC systems have a lot of features, and it is presently being used in industries where accuracy is of prime importance, such as aerospace and medical devices as well as automotive and electronics manufacturers since modern CNC systems can achieve very tight tolerances down to + or – 0.0001 inches.

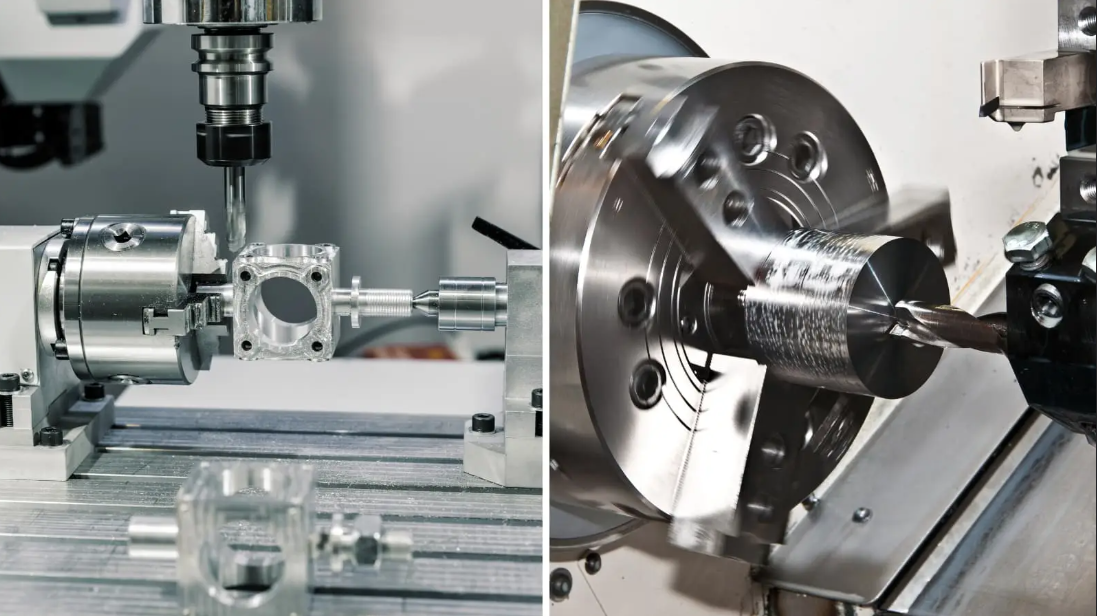

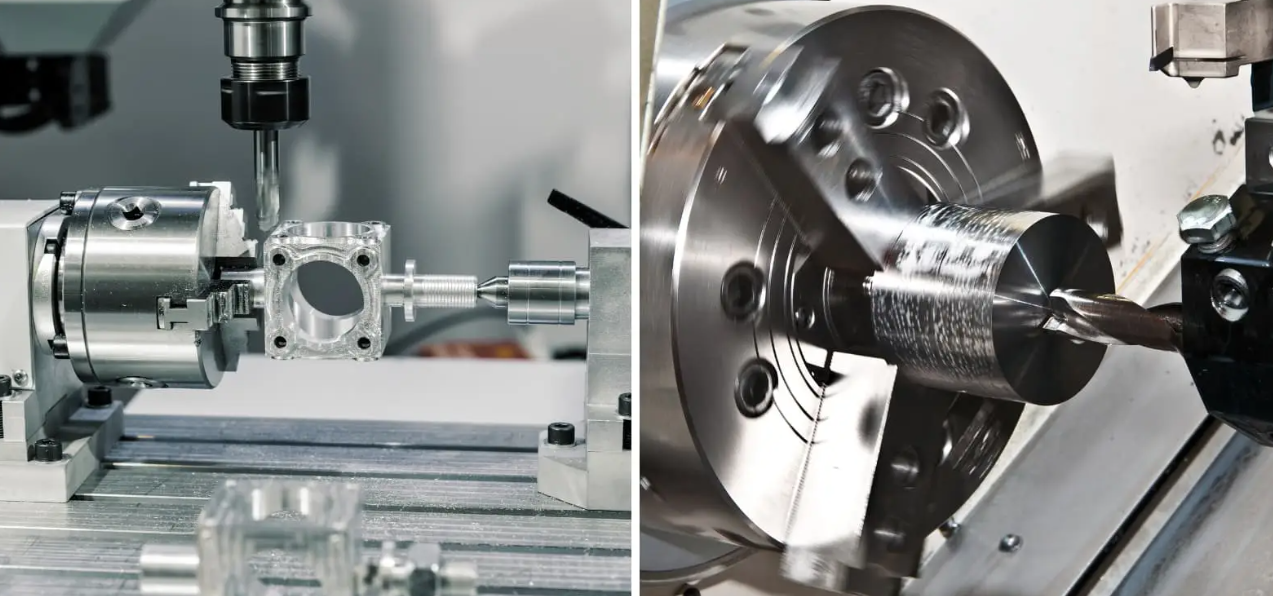

Understanding CNC Lathe Operations and Capabilities

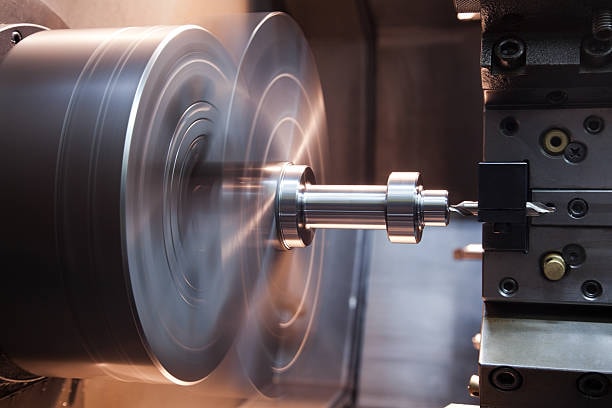

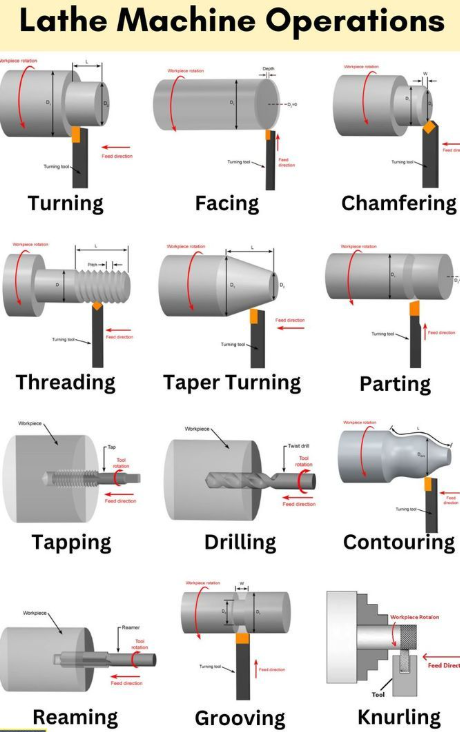

The concept of a CNC lathe is rather simple and at the same time very strong: the material is cut under the action of stationary tools as the piece rotates. It is this rotational movement that enables lathes to do an exceptional job of producing cylindrical, conical and symmetrical components, even when the stationary workpiece is in motion, with blistering speed and accuracy.

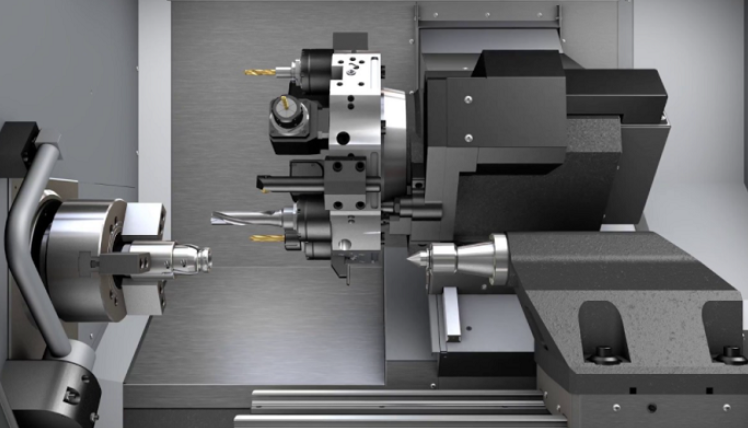

A CNC lathe spins the piece or bar stock about the tools which cut into shape. Cutting tools come to the spinning workpiece at different angles enabling the operators to cut external and internal features like threads, grooves, tapers, and complicated contours.

The use of CNC lathes is especially advantageous when the manufacturing schedule requires large volumes as the setup process is by no means complex and the cycle times are much shorter than that of milling. The machines have a much potential to go prolonged without many touch ups by the operator when appropriately programmed and calibrated, which makes them most suitable in producing automotive parts, plumbing outfits, and mechanical hardware.

CNC Mill Functionality and Manufacturing Applications

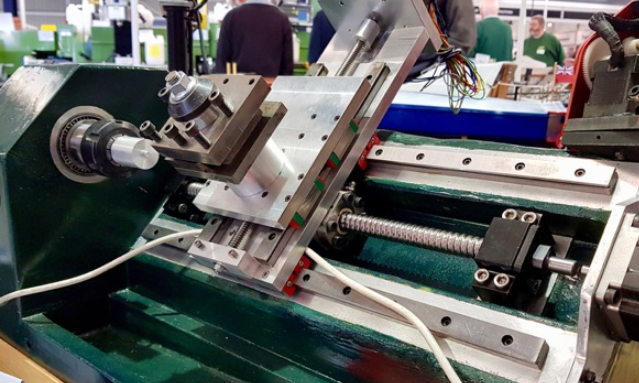

CNC mills are designed along an entirely different setup of operation in contrast to lathes. On a CNC mill, cutting tools perform peripheral milling by spinning around the bar stock while the workpiece does not move or moves along a variety axes. This set up allows mills to make intricate three dimensional geometries, flat surfaces, pockets, slots and complex three dimensional shapes.

The advantage of CNC mills is that they are multi-axis and nowadays new machines are available with 3, 4 or even 5-axis simultaneous functions. This flexibility enables the manufacturers to make parts in complex angular features, undercuts, and more complex shapes or compound curves that are quite impossible or challenging when producing them using the lathe cnc milling machine.

The CNC mills are the best in terms of prototype work production as well as low to medium size batches and also in special parts that need multiple activities in a solitary installation. Examples of industries using CNC milling include the aerospace industry, medical device manufacturing and precision tooling to produce critical parts that require very complex geometries cnc lathe rotates

.

Key Operational Differences Between CNC Lathes and Mills

The major contrast between a CNC Milling Process and CNC Lathe Process is the part and machines rotations. This basic difference in the z axis fluences as far as design considerations of parts, complexity of programming, as well as efficiency of production rotating cutting tool.

The workpiece in a lathe is rotated to high RPMs and cutting tools are relatively stationary which gives the cutting tools good chip clearance and causes chips to flow out of the cutting area. This arrangement smoothly extends to cylindrical and rotational workpieces whereby the removal of material takes place in a continuous flowing action machine shops.

Milling is a subset of operation that uses rotary cutters, which plunge, traverse or climb across workpieces held stationary. The shearing motion is more periodical with every cut coming into contact with the material and relensing the material repeatedly. This repetitive cutting process provides more geometric freedom but might need more advanced programming and set up protocols.

There is also a big variation in the programming complexity of the two machines. The more common are two-axis programming (X,Z axes) in Lathe, and three axis or more people programming in milling (more complex in the program, but more versatile) modern machine shops.

Part Geometry and Design Considerations

A CNC-lathe suits well to conical or cylindrical parts; a CNC-mill is suitable to more sophisticated shapes. These limitations and benefits in geometry are vital in assisting in the determination of which machining technique to use on your particular parts injection molding.

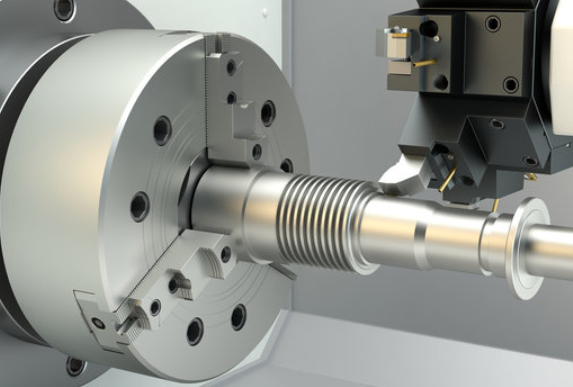

CNC lathes are good at making parts that have a rotational symmetry, such as shafts, bushings, flanges, and threaded fasteners, turned components. The inherent rotation capacity of workpiece is considered useful to work into smooth surfaces finishes on cylindrical surfaces and also in the operations where the consistent wall thickness is required around a central axis.

CNC mill will be able to achieve flat surfaces at any occasion, create deeper holes, and also create pocket, planes, grooves, or edges. This is what makes mills the mainstay in the production of the parts that need flat surfaces, square features, very tricky pockets, keyways and angular geometries unattainable by rotational machining x axis.

During part design engineers should also take into consideration the available machine capabilities early on in the design so that they are making design decisions which will yield to the machine capabilities. The design of the parts to be produced on the lathe should utilize as many cylindrical design areas as possible, ensuring proper use of the tool holder, and have as little flat surface or non-rotatable areas to avoid having second operations y axis.

Material Compatibility and Machining Considerations

CNC lathes and mills are capable of working with a diverse array of materials ranging anywhere between different metals, plastics, and composites. Nevertheless, the wrong machine selection when machining tough metals may greatly affect material consumption and surface finish quality, including overall efficiency of the process in accordance with the peculiarities of the material.

There are materials, which work-harden in a cutting process, e.g., stainless steels and some nickel alloys, where continuous cutting by a lathe can be advantageous. This constant chip formation and cutting force makes it easy to have consistent temperatures and work-hardening is minimised because of a constant cutting action rather than a start-stop action like milling.

On the other hand, some materials that are likely to chatter or vibrate in a cutting process might respond advantageously to milling processes where cutting parameters could be controlled more accurately and cautiously using variable feeds, speeds, and tool engagement plans. The more inflexible workholdings of milling machines are beneficial as well in the machining of thin-walled or fragile parts that would be likely to deflect under the rotational energy of a lathe machining procedure.

The coolant capabilities normally found on a milling machine could be useful in coming up on heat sensitive materials (such as some plastics, and aluminum alloys) and have a better control of temperature when extended cutting operations need to be performed.

Cost Analysis and Production Efficiency Factors

The use of CNC lathe as an alternate to CNC mill goes beyond the capital cost upfront of the machine and cost of operation. The volume of production, complexity of set ups, cycle times and labour costs also add to the cost of a part and general efficiency of manufacture.

CNC lathes tend to be less expensive per-part and have a faster, easier program and shorter set up time per-part, when making high quantities of suitable parts. Lathes are especially economical in parts that lend themselves to doing all the work using the same set up and do not require re-positioning of such a set up.

Milling jobs can be more expensive per part when cycle times are longer and more complicated programming is necessary, however they are much more versatile, and parts that could easily take several set-ups on a lathe can be manufactured quite quickly. When a prototype or only small quantities are being produced the flexibility of milling can be considered as more important than increased cycle times.

Cost analysis also takes the labor factors seriously. With experience, lathe operators are often able to handle multiple machines at a time because turning is a predictable process, although milling may need more exclusive attention and especially when more complex multi-axis machining is to be done.

Quality Control and Precision Capabilities

Although CNC lathes and mills are equally capable of extreme precision and surface quality control provided that they are taken care of and handled skilfully. Nevertheless, the type of each machine will have its natural strengths depending on the quality requirement and measurement factors.

With regard to efficient practice, CNC lathe and milling machine are characterized by the ability to work in a close tolerance, usually stated in plus or minus 0.0001 inches (0.0025 mm) or even small. Accuracy is determined by issues such as machine maintenance, the quality of tooling and work holding equipment and environmental issues.

Naturally, CNC lathes have a specialization of holding constant diameter, concentric and cylindricity since they undergo rotational machining. The cutting action- which goes on continuously is generally attributed to higher quality surface finishes on cylindrical surfaces than with milling. Also the thread cutting on the lathes usually prove more precise and effective than their thread milling counterparts.

The milling machines are convenient in holding flatness, perpendicularity, and other complicated geometric correlacies among features. Capability of referencing multiple surfaces and features in the same setup can have the overall result of higher part accuracies in a complicated geometry.

Industry Applications and Specialized Uses

CNC lathes or mills have different preferences among different industries depending on the perquisites of some industries, part shapes, and quality. Gaining access to such industry preferences can assist with the choice of the machines and investment planning.

Automotive sector depends a lot on CNC lathes to make engine parts, transmission components, and other drive train parts where the cylindrical parts are needed in large volumes. Such shafts as crankshafts, camshafts, and others utilize the effectiveness and accuracy of turning processes.

Lathes are usually needed to make landing gear parts, engine parts and structural parts of any particular machine whereas the mills are needed on multi-axis parts, brackets and other parts with complex geometries with the help of mills.

Surgical instruments, implants and components of vascular tubes and diagnostic instruments in medical device manufacturing commonly utilize CNC milling to obtain the complex shapes and high quality surface facilities demanded. Lathes, however, are crucial as medical machineries in manufacturing components of catheter, surgical screws and other medical instruments cylindrical in shape.

Both machines are widely used by the electronics industry with connectors pins, threaded standoffs and cylindrical parts being produced by lathes and printed circuit board heat sinks, enclosures, and frequently complex electronic housings where tight dimensional control is necessary, being made by mills.

Conclusion

Deciding between CNC lathe and CNC mill work is a complicated decision that needs to be well thought out based upon the geometry of the part, the number of parts being produced, the materials being machined as well as the quality. The CNC lathe is very effective and efficient in producing cylindrical and cone shapes and therefore, it is the best type of lathe to produce parts in high quantity in rotation. They can frequently be programmed and set up more simply, leading to a relatively low cost-per-part of appropriate applications.

CNC mills provide higher abilities to cope with complex geometry, flat surfaces, and intricate features that are not possible to be carried out by rotational machining. Mills can have longer cycle times and more complex programs but are used where flexibility is required to develop prototypes, more complex parts and dedicated applications that need the multi-axis capability.