Two grades of aluminum alloys always emerge as the most favored by the industry when they are chosen in terms of engineering use one is 6061-T6 and the other is 7075. Each of the two alloys both has different mechanical properties that make them well-suited to different uses, such as components of an aircraft up to casual goods. Being familiar with their own peculiarities, production peculiarities, costing is of great importance to take reasonable decisions in terms of material selection, particularly due to their good machinability .

What is 6061-T6 Aluminum?

6061-T6 aluminum is a part of 6XXX series of aluminum alloys, which has magnesium and silicon as the main elements in its alloying composition. The 6061 is one of the widespread, medium-strength alloys. The T6 designation means that this alloy has been solution heat treated and artificially aged, the mechanical property optimalized by this treatment scheme in all-purpose applications.

Understanding 7075 Aluminum Alloys

7075 aluminum belongs to the 7XXX family of alloys and is characterized by zinc as its major alloying material accompanied by magnesium and copper. 7075 is a member of the 7XXX and it is one of the strongest aluminum commercial alloys available, with a higher melting point than other alloys . Being such a high-strength alloy, it is commonly compared to steel by the measure of strength-to-weight that makes it priceless in applications with such requirements.

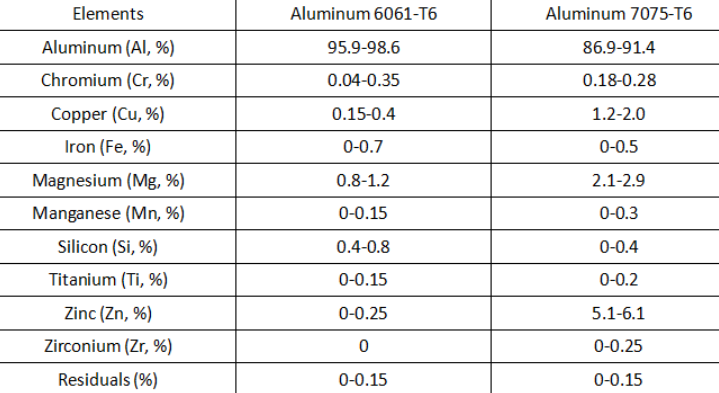

Chemical Composition Differences

Basic distinction among these alloys is their chemical content. 6061 will possess more silicon and 7075 will denote quite a more number of zinc. The 6061-T6 has around 0.8-1.2 per cent magnesium and 0.4-0.8 per cent silicon whereas 7075 has 5.1-6.1 per cent zinc, 2.1-2.9 per cent magnesium, and 1.2-2.0 per cent copper. Such compositional variations have direct effects on their physical properties, mechanical properties, and performance characteristics.

Strength Properties Comparison

Comparing the mechanical strength, 7075 aluminum works much better than 6061-T6. The tensile strength of 7075 T6 aluminum in the T6 state almost equals twice the strength of 6061 T6 aluminum. The alloy 7075-T6 tends to have a tensile strength of 570 MPa (83 000psi), whereas 6061-T6 has just over 310 MPa (45 000psi). This significantly puts 7075, which has a higher melting point, as the common material of choice in high-stress purposes.

Shear Strength Analysis

Another important performance requirement in which 7075 aluminum is superior is the shear strength. It is believed that 7075-T6 aluminum has a 1.5 greater shear strength when compared to the 6061-T6 aluminum. In particular, the Shear Strength of 7075 T6 aluminum is 331 MPa/ 48000 psi, 6061 T6 aluminum Shear Strength is 207 MPa/31000 psi. With this excellent shear strength and good thermal conductivity , 7075 is suitable in applications where there are forces like cutting or torsional stress.

Machinability Characteristics

There is a great difference in Machinability of these two alloys. 6061-T6 aluminium has excellent machinability with good surface finishes and little tool life concerned. It has balanced composition and can be cut efficiently, drilled and milled. Conversely, 7075 aluminum, achieves greater hardness and is more work-hardening prone, and therefore must be considered more carefully with regard to cutting parameters depending on the desired outcome of the part to machined.

Weldability Properties

Among the major benefits of 6061-T6 aluminum there is excellent weldability. 6061 aluminum is formable and weldable with the addition of magnesium which acts as its major alloying elements, ensuring good formability . The alloy is readily welded using different methods such as TIG, MIG and resistance welding, thanks to its protective oxide layer . On the other hand, 7075 aluminum being a much harder metal with increased concentration of zinc is more unfriendly to form and weld.

Formability and Workability

These alloys exhibit very different formability attributes since they have contrasting composition and strength features. Aluminum 6061 T6 is an all purpose alloy. It is not as strong as aluminum 7075 T651 though it is more plastic. This increased ductility provides greater formability and bendability pure aluminum, and 6061 T6 can be formed and bent without cracking, suitable to material used with complicated forms and functional parts, leading to a higher presence of aluminum oxide aluminum metal melting point.

Corrosion Resistance Performance

Both alloys are reasonably resistant to corrosion, but by different mechanisms. 6061-T6 aluminum has good resistance to atmospheric corrosion and reasonably good in a marine environment when properly treated btu in hr ft. 7075 aluminum is generally resistant to though in some environments may be more prone to stress corrosion cracking due to the high strength nature of the alloy as well as the zinc content low melting point.

Cost Analysis and Economic Factors

In the process of selecting materials, economic factors are very essential. In comparing 7075 aluminum to 6061 aluminum, the 7075 alloy is more expensive relatively. The increased price of 7075 is associated with the more complicated composition of the alloying elements, especially, zinc, and more rigid requirements of the production, which can affect energy efficiency, often requiring more energy during the production of cast alloy. In cost sensitive applications, where modest strength is acceptable, 6061-T6 offers a more cost effective alternative aircraft fittings.

Weight Considerations

Both the alloys present similar properties on density with the density of 6061-T6 aluminum to be approximately 2.70 g/cm 3 (2.7 g cm) and 7075 aluminum at 2.81 g/cm 3. This minor variation implies that 7075 is a little bit heavier though the difference is imperceptible in most of the practical usages production process. Both the alloys have good strength to weight ratio and favorable thermal properties over steel substitutes at high temperatures.

Aerospace Applications

Alloys have various uses in the aerospace industry, and both of them are heavily used. 7075 aluminum is most typically used in aircraft frames and/or plastic mold tooling and/on high-end bicycle components etc. It is very strong, so it can be used in important structural parts, wing spars and fuselage frames where weight savings and high strength are common protective layer.

Automotive Industry Uses

The 6061-T6 aluminum is also used extensively in the automotive industry in chassis parts, body panels and heat exchangers. The common application of aluminum 6061 T6 is in the automobile and marine industries. It is strong enough in its moderation, is highly formable, and also affordable enough to make it applicable in mass automobile manufacturing appliance fittings.

Marine Environment Applications

The corrosion resistance of both alloys is utilized in marine applications. High weldability is the advantage of 6061-T6 aluminum, which is used on the hulls, masts and marine hardware, where it can be anticipated that repairs may be made in the field. It has become a standard material in the marine industry by virtue of its resistance to salt water as well as its easy manufacturability.

Manufacturing Process Considerations

These two alloys have different manufacturing processes owing to different properties. The high workability of 6061-T6 makes it suitable to perform complex extrusion, deep drawing and intricate machined parts. The T6 temper gives the greatest strength that is still workable. 7075 aluminum often mandates more special process control, and may require intermediate annealing of a complex forming operation desired properties.

Heat Treatment Requirements

The two alloys enjoy a good heat treatment but they have varying needs. T6 tempering of the two consists of solution heat treatment and artificial aging. The aluminum 7075, however, demands a more accurate control of temperature and timing owing to its multi-elements formula. Final mechanical properties are greatly influenced by the heat treatment procedure and hence it should be well-regulated pure form.

Quality Control Standards

Both alloys are typically inspected to aerospace and automotive standards of quality, particularly those that are heat treated for enhanced performance . 7075 aluminum may more frequently come with stricter guidelines depending on the application, which in extreme cases may be a life critical application hydraulic pistons. The both alloys require non-destructive testing, verification of the chemical composition, and validation of the mechanical properties, but in the case of 7075, the quality assurance procedures usually need to be calibrated to an even higher level of precision heat treatable.

Surface Treatment Options

Both alloys accept most surface treatments such as anodizing, powder coating, and chemical conversion coatings. 6061-T6 aluminum will usually anodize to be uniform in color since it is relatively well balanced fatigue strength. 7075 aluminum is more difficult sometimes to anodize evenly because the copper in its composition can cause some differences in color.

Environmental Impact

Environmentally, both the alloys are easily recyclable with their properties being sustained after being re-cycled several times. The energy to produce primary is different by slightly where 6061-T6 is slightly energy intensive in comparison to the other composition because it has a simpler composition other metals. The two alloys are part of the sustainability program as they can be properly recycled at end-of-life, which includes processes for aluminum melting .

Future Industry Trends

Development in the industry signifies that the usage of aluminum alloys in various industries is set to increase. Combined with more advanced manufacturing techniques, which involve additive manufacturing and novel forming processes, both 6061-T6 and 7075 are now increasing in applications. Explorations are being made into further refinements of such alloys concerning upcoming tasks in electric vehicles, renewable energy technology, and high-flying aerospace platforms.

Conclusion

The knowledge of peculiarities of 6061-T6 and 7075 aluminum alloys allows the engineers and manufacturers to make correct decisions when choosing the material. Although there may be certain high strength applications which may require maximum performance aluminum 7075 offers, 6061-T6 aluminum offers basically a balance of properties, workability and cost effectiveness to a wider variety of applications. Check your individual needs in terms of strength, formability, weldability and budget so that you could pick the most appropriate alloy to match your project requirements.