The contemporary production requires accuracy, effectiveness, and flexibility. With industries advancing to more intricate geometries and increased tolerances, 3-axis and 5-axis CNC machining becomes especially relevant and one may argue that the distinction between the two is essential for manufacturing intricate parts . The most significant distinction between 3-axis, 4-axis and 5-axis machining is the extent of the motion, in which both the work piece and the cutting tool can move, around each other. This very difference has an influence on such things as production costs, the complexity of parts and manufacturing schedules.

This is of particular importance to both experienced manufacturers considering taking equipment upgrades and first-time owners of CNC machining equipment as only when the strengths and weaknesses of computer numerical control technologies are understood can decisions be made intelligently. In this definitive guide we are going to be going into a lot of technical terms, including how the machine bed impacts your choice concrete applications as well as the aspects of strategy that ought to drive your decision between 3-axis CNC systems versus the 5 axis.

Understanding 3-Axis CNC Machining Fundamentals

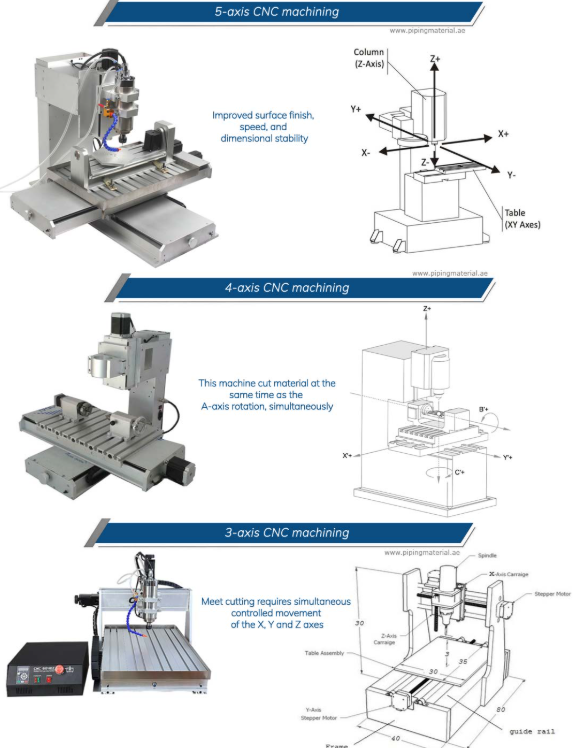

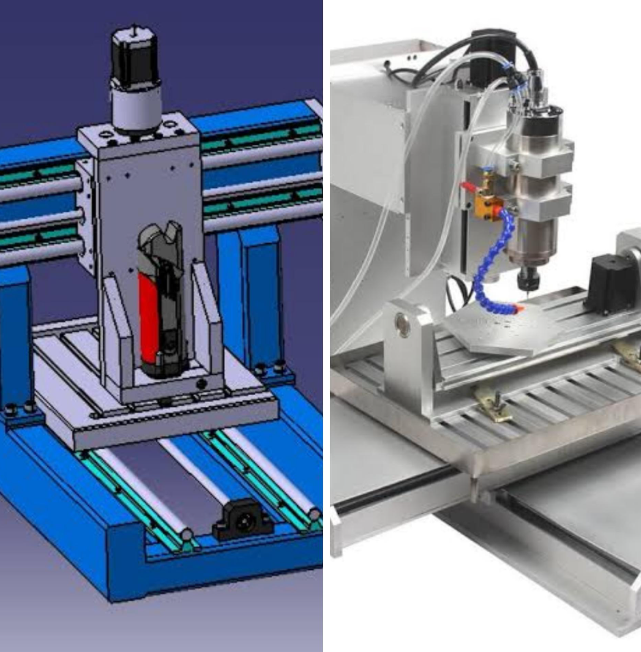

The modern subtractive manufacturing is based on the three-axis CNC machining. In the 3-axis machining, the tool is able to move in three different directions independently or concurrently with respect to material. It has the capability of moving along the X, Y, and Z linear axis. This linear movement system allows the cutting tool to get accessed to the workpiece through the above position, as the moving part of the system moves in three perpendicular positions allowing accurate cuts to be made and workpieces designed.

X-axis is normally used to control the side-to-side movements, Y-axis to control front-to-back movements and Z-axis is used to control up-and-down positions. Depending on this configuration, it is possible to create features such as slots, holes, pockets, and contours on the top surface and the sides of workpieces. Nevertheless, the rotation of the workpiece is usually made static in the course of machining process, with the restrictions imposed on certain features and some intricate shapes that may involve many directions.

3-axis systems are best suited in the production of parts with relatively easy geometries and thus it is best suited where economy in using the system and ease of configuration are an important aspect. The technology has also proved to be very durable in all sectors including automotive parts and consumer electronics where high quality, the ability to remove material efficiently, and predictable cost of production is vital.

Configuration of 3-axis machining would be not very complex usually considering simple workholding fixtures and tool paths to be programmed. Its ease of use translates to less time to set up systems, reducing the need for multiple setups minor program complexity, less skill on operators and this might be an appealing manifestation in most manufacturing set ups.

Exploring 5-Axis CNC Machining Capabilities

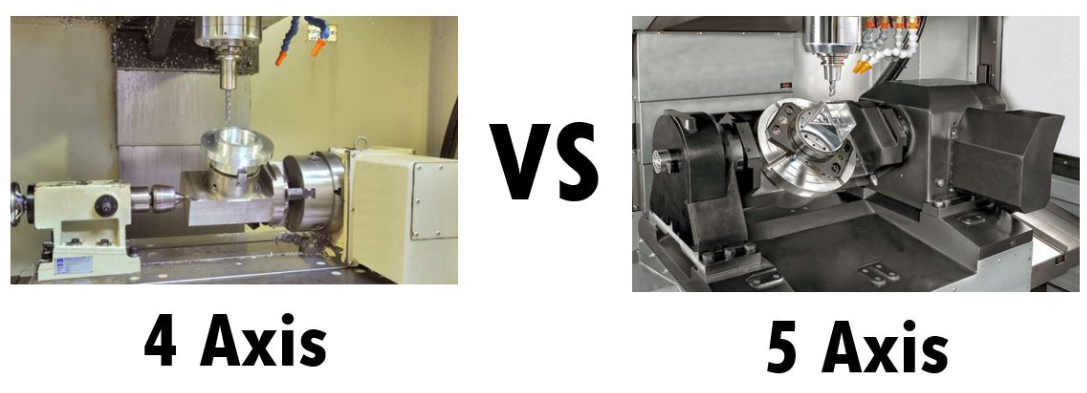

The revolution that comes with five-axis CNC machining is incorporating two rotational axes together with the three linear moving directions. Unlike the traditional 3-axis CNC movement based on the motions along Z, Y, and X axis, the 5-axis CNC machine also has two axes of rotation that is usually named A-axis and B-axis (or A-axis and C-axis, depending on the form).

These added rotating axes can allow the work piece or a cutting tool to twirl around the straight axes to give them access to complex shapes never before possible. The A-axis normally rotates on the X- axis, whereas the B-axis rotates on the Y-axis (or C-axis on the Z-axis). The five-sided machining ability in a single setting is via the multi-directional nature and the additional axis that the machine has, which can really decrease the amount of fixtures and repositioning settings needed.

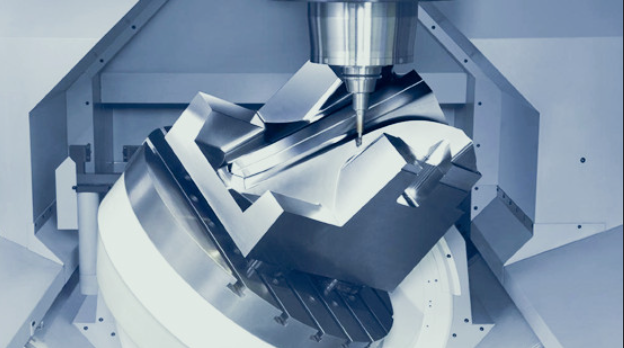

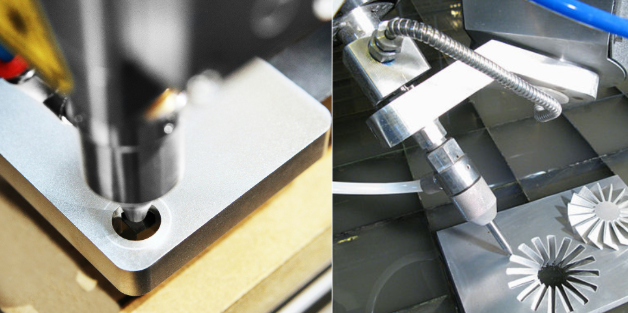

All the five axes move together to form what is called continuous 5-axis machining whereby the cutting tool is always at optimal cutting angles during the whole of the machining process. This facilitates creation of curvature that is more complex, internal geometries, and allows for greater accuracy in the production of parts with undercut which would otherwise not be possible or very difficult to produce with 3-axis systems.

CNC machine with 5 axes have the ability to cut on 2 more axis than CNC machines with 3 axis. The fact that these routers can cut 5 sides of a piece of material at one go increases the capabilities and flexibility of the operator. This increased ability introduces possibilities of producing parts of equipment aerospace, medical equipment, prototype cars and artistic works that require complex three dimensional shapes, but it does require a significant investment .

Key Technical Differences and Specifications

The electrical differences between 3-axis and 5-axis CNC system go way further than simply the number of axes. The discrepancy in these two types of CNC machines comes in the movement of their tool; one has three and the other has five. This factor, though it appears to be minimal, makes a whole difference in machining capacity and system complexity.

One of the more important technical distinctions is the control systems. Five-axis machines need complex CNC controllers that can arrange multiple axes movements properly as well as having the capability of following precise interpolations among all axes simultaneously. The complexity of it requires sophisticated collision detection, tool head management tool path optimization and feedback of real-time position in all axes at the same instant.

The precision that is required by the mechanism is considerably more in 5-axis systems. A special 5-axis machine tends to be substantially stiffer. This is due to the fact that it must achieve accuracy which needs to be achieved at a time when it is performing a myriad of tasks in numerous directions. This accuracy implies tighter tolerances even on a fairly complex part. The machine should support the dynamic loads that come on it in any direction without reducing the accuracy of the positions.

Tool holding systems and spindle are also highly varied. Five-axis machineries usually have more heavy duty spindle system which can support cutting at different orientations. Tool length compensation gets critical since the effective length of the cutting tool varies with those orientations and necessitates complex and elaborate measurement and compensation mechanisms.

5-axis systems exponentially enhance the issue of programming complexity. Although 3-axis programming considers linear tool paths and basic contouring, 5-axis programming will require more attention to the direction of the tool, possible collisions, and the best coordination of the axis during the whole process of machining.

Manufacturing Applications and Industry Uses

The scope of usage of 3-axis and 5-axis cnc cutting corresponds to the basic differences in their capabilities. The favorable selection of three-axis systems is in high-volume production settings where part geometries are not complicated and the cost performance is a major focus. General manufacturing, electronics enclosures, basic automobile components and basic tooling are among the industries that are dependent on 3-axis capabilities.

Typical areas of use with 3-axes are machining of flat panels, straightforward mold making, basic prototyping as well as the manufacture of components with largely 2.5D forms. The technology has a high level of reliability, predictable cycle times and reduced level of operational complexity which is beneficial with machining parts in these applications. Schools and small machine shops tend to order 3-axis systems because of their ability to perform various, relatively simple projects.

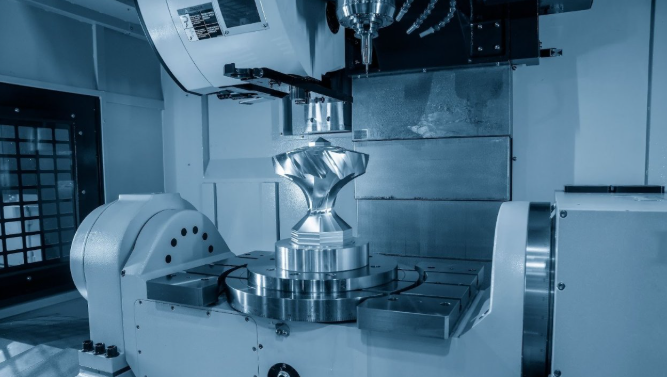

The area where five-axis machining fulfills its niche is in the production of high value complex components. Aerospace uses 5-axis systems to manufacture turbine blades, structures that are complexly curved and parts with angled features that need superior surface finish in various directions. Machining of surgical tools, orthopedic implants, and precision components of diagnostic equipment are used by the medical device industry by use of 5-axis.

The automotive racing and luxury automaker suppliers utilize the custom 5-axes usage on engine parts or airfoil sheet body, and specialty tooling. The technology is particularly strong in making prototypes when the complexity of design is beyond what conventional manufacturing can achieve, and so that design can be tested without having to engage in choice, assembly of machine-specific tooling.

A second important area of application of 5-axis technology is in the mold and die making. The 5-axis capability of complex injection molds with complicated cooling systems, undercuts, and curved part lines can bring substantial benefits, decreasing the manufacturing time and improving the surface finish of injection-molded parts, when compared to the traditional ones.

Cost Analysis and Investment Considerations

The economic consequences of deciding to adopt 3-axis CNC system or 5-axis CNC system do not end with the one-time expense. The 3-axis machines are usually cheap to purchase, but the overall cost of ownership comparison should take into account not only the productivity, part complexity capability, but also should discuss the long-term operational efficiency.

First time investment on 3-axis systems is mostly moderate to large according to size, precision necessity and robotic like aspects. These machines provide a good indication of the expected returns in investment because they are also predictable in terms of what they can produce and the reduced complexity in operations. The cost of maintenance is expected to be reduced because mechanical systems of shorter complexity and not many moving elements are the elements that are to go through precision calibration.

The five-axis systems are sold at high prices because their mechanical systems are complicated, they involve advanced control technology as well as precision requirements. This can pay off however, with lower set up times, no need to replace numerous fixturings, and the ability to manufacture mechanical components that are impossible using a 3-axis platform. Single-setup machining is capable of radically shortening overall production time on complex part.

Compared to 3 5 92 uncertainty axis machines that require only simple workpiece fixturing, 5 92 uncertainty axis machines have several much more complicated setup requirements due to simultaneous axis control and to the collision detection requirements. This complexity has the effect of demanding increased levels of skill in programming and in operation, which may entail higher labor costs, but which may also yield products of greater value.

Skill development and training are major continual expenses of 5-axis systems. To acquire program knowledge, knowledge on running the machine, and to troubleshoot consumes a lot of time and money. Nevertheless, companies that implement 5-axis technology successfully discover that they have a possibility to undertake projects offering greater values and to charge premium prices to their services.

Advantages and Limitations Comparison

Three-axis CNC machining has great benefits in most of manufacturing applications. Ease of programming, use and servicing gives a manufacturer new to CNC technology an easy segment of entry. Recruitment and the cost of training are cut because of the large supply of 3-axis-trained staff. Established end mills and cutting tools costs are not very high and can be easily purchased via many suppliers.

Another important benefit of 3-axis systems is reliability. There is less to go wrong and less control machinery, which usually equates to greater uptime and more predictable maintenance intervals. The programming of parts may involve a shorter duration linear axes, especially when creating threaded holes and the verification methods are mostly easier, thereby leading to a reduced project turnaround time three linear axes

.

Nevertheless, when the part becomes more complex it is revealed that 3-axis cannot be used. The parts that have features on their common plane will have many set-ups, which add to the handling time, and in between the set-ups, there can be accuracy problems also rotation axes. The complex shapes are sometimes not feasible and so the shape of the design cannot be changed freely thus new methods of fabrication or part redesign are needed.

The problem with five-axis is geometric capability and manufacturing efficiency of complex parts. Single setup machining: There is no mistake of set-up and handling time of multi-sided parts is minimized. Excellent surface finish options, including the ability to create sharp edges, are achieved due to the best tool setting during the cutting process. Using shorter and stiffer cutting tools in hard-to-reach places make cutting work more accurate and extending the life of the tool both the workpiece.

5-axis system programming sophistication can be considered as limitation as well as a strength. Whereas more detailed software makes possible amazing geometric power, it requires increased expertise and takes more program time to accomplish continuous machining. The curves of initial learning are steep, and the software expenses of advanced CAM systems are huge.

Making the Right Choice for Your Business

The choice of 3-axis or 5-axis CNC technology is a difficult task that should be made by the taking into consideration of the present requirements, development strategies and positioning in the market. Degree of axes is the movement of a cutting tool. As such, the cutting tool movement is the most advanced with the 5 equivalent axis CNC machining, allowing for intricate planar milled profiles . This relative ability to do so must match with your applications and competition strategy.

Consider the normal parts complexity and geometrical needs. 3-axis-systems can be cost-effective when you produce relatively simple parts; the geometries are uncomplicated and can be shaped in various linear directions . But when your capacity requires Chinese machine tools to meet the needs of your market if you are large enough to contemplate expansion to higher-complexity applications then 5-axis may be required as a competitive But when your capacity requires Chinese machine tools to meet the needs of your market if you are large enough to contemplate expansion to higher-complexity applications then performance may be required as a competitive necessity cnc milling machines.

Assess your own capacity in the workforce and training willingness. As compared to three-axis machines, three-axis systems do not demand as specialized a knowledge and are thus best utilized by organizations that either have little CNC experience or value simplicity of operations. The five-axis systems require substantial training expenditure, yet have the capacity to occupy the more profitable market segments.

The cost of ownership which includes equipment, training cost, software, tooling and maintenance cost, then, should be covered in financial analysis. You also need to consider the possible effects of increased functions to the revenue as well as the competitive prospects that advanced technology may result in your market.

The presence of positioning in the market is important when it comes to choosing technology. Both 3-axis systems and 5-axis systems can fit your strategy if you are an organization that only needs to compete on price and 5-axis systems could be the appropriate strategy to fulfill when an organization is interested in producing high value, complex products.

Conclusion

3-axis CNC as well as 5-axis technologies play critical functions in contemporary production. The key to success is to choose the piece of technology that can best accommodate you according to your current needs and development plans and where you would like to position yourself in the market. What may be most important is that once you have determined whether you want to focus on being cost-effective with 3-axis systems or delve into higher capabilities with 5-axis technology you need to align your decision with your manufacturing needs and business goals.