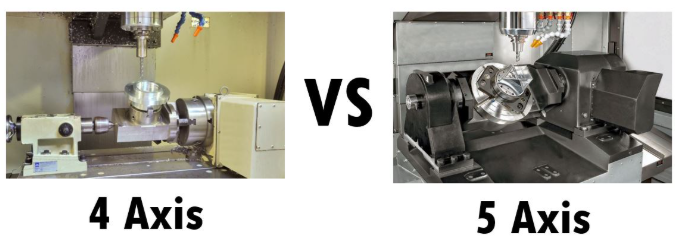

Learn more about the major distinctions between the 4 axis and 5 axis CNC machines and the various machining processes involved . Our precision manufacturing comparison guide will show you which machining technology is most suitable to your manufacturing business.

The current competitive environment in manufacturing industry dictates that the CNC machining technology you adopt will lead to success or a failure in your production processes and the quality of your machining parts. Since a 4-axis and a 5-axis machine have different capacities and technologies, and rotational axes operate independently s the CNC technology has developed to incorporate touchscreen control, robots, and multi-axis machine, it is essential to comprehend the distinctions between these machines, as well as the cam software used, to have optimal output and productivity once one is a manufacturer. In the decision between 4-axis CNC and 5-axis CNC capabilities, whether you are contemplating moving manufacturing in-house or refreshing production capabilities, this guide will give you appropriate critical thinking overview in the present circumstance.

Understanding the Fundamentals of Multi-Axis CNC Machining

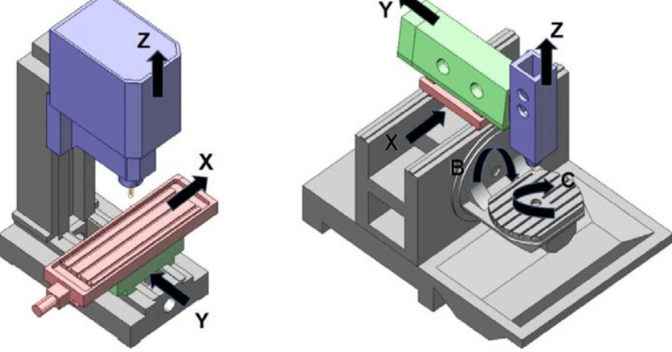

The multi-axis CNC machining is a huge improvement to the 3-axis machines used in the past whose cutting tools can only move along their three linear axes: X (side to side), Y (back to front), and Z (up and down). Although the 3-axis systems are best at producing flat surfaces and simple geometries, they also involve cutting tool movement that requires multiple setups parts with complex geometries and features on various faces or at various orientations.

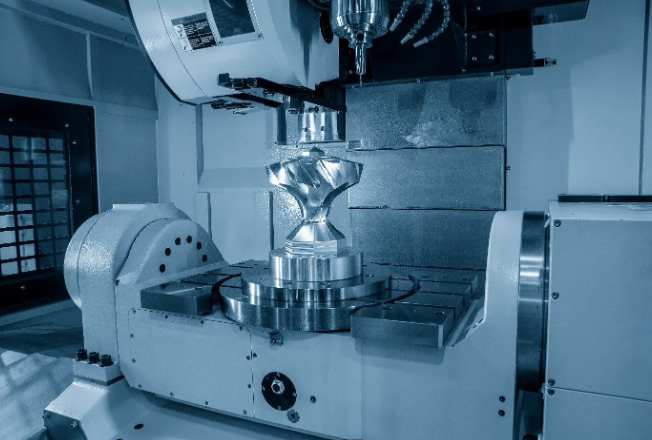

The limitations are overcome by developing to 4-axis and 5-axis systems which provide some rotation. These extra axes, including a axis rotation, will enable the part or the cutting tool to rotate and access many sides without moving the part. This new technology has transformed precision manufacturing, especially in the spheres of aerospace, automotive, in medical gadgets, and mold-making.

Multi-axis machining is filled with general advantages irrespective of whether you select 4-axis, or 5-axis systems, as the more complex the motion, the greater the benefit . These are shorter set up times, better surface finishes leading to superior surface finish , better accuracy because of capability to machine a smaller set up and ability to produce complex shapes which otherwise would have been impossible or incredibly time-consuming with conventional techniques. Before getting into details of the 4-axis versus 5-axis systems, it is necessary to understand these fundamentals.

4-Axis CNC Machining: Capabilities and Applications

The 4-axis implementation adds one more axis (rotation) (usually referred to as the A-axis) to the 3-axis of XYZ. This rotational axis enables this workpiece to rotate about an X-axis and the two rotational axes further ensure that four sides of a part may be reached with only one set up. The ability is a huge addition compared to 3-axis systems, which would take numerous setups to achieve the same.

The 4-axis system can be performed in two different ways which include indexing (also referred to as 3+1) and simultaneous machining. In 4-axis milling (3 + 1), indexing is done to bring the workpiece to a position such that the 3-axis milling plans can then be exploited. This is best suited to those parts that have features on more than one face and that could be reached by adjusting the workpiece to certain orientations. Parallel 4 axis machining instead will enable the cutting tool to traverse the 3 linear axes as well as the workpiece to rotate continuously so that complex curved surfaces and helical detail can be cut.

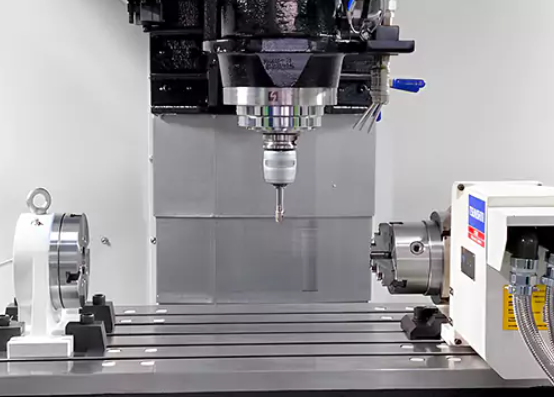

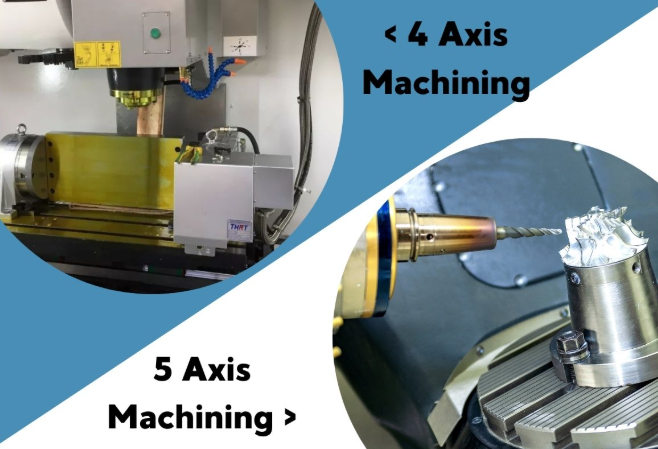

The 4-axis machining is very much in use in situations where there is a need to work with the cylindrical parts, complex brackets, components with holes in two or more faces. When the cut-outs and holes are placed on the side of a part or even made on a cylinder, 4th axis machining is the one that will be applicable. Automobile, aerospace, and general manufacturing industries are commonly applying 4-axis systems in manufacturing engine parts, transmission components, and structural brackets, in which excellent precision and efficiency play vital roles.

5-Axis CNC Machining: Advanced Manufacturing Capabilities

5-axis CNC machining is the highest point in the present technology of machining and provides utmost flexibility with amazing precision in manufacturing the complicated parts. There are variations of 5th axis machines just like 4 th axis machines. Either they have a rotation in the A-axis and C-axis or the rotation in the B-axis and C-axis which is applied by the machines usually. The dual-rotation feature enables both the workpiece and the spindle to rotate, letting us reach any surface of a part virtually without removing the tool to switch positions, thus ensuring the quality of the final machined part .

There are two main categories of 5 axis machining, simultaneous 5 -axis and 3+2 indexed machining. In case of simultaneous milling, the cutting tool is in YZC (or XZC) at the same moment as the other two axes (A and C or B and C). The process enables a very intricate sort through 3D shapes and curves, including complex arcs, to be created. Concurrent 5 axis machining is especially effective in making sculptured surfaces, intricate aerospace parts, medical implants in which a smooth surface finish is essential.

Though it does not use all five axes at the same time, 3+2 indexed machining has still a lot of advantages to offer over counterparts. The workpiece is placed at definite angles when the rotational axes are used in this mode and this enables the use of 3-axes machining strategies on normally inaccessible surfaces. Such a method can be cheaper and simpler to code than complete simultaneous 5-axis cutting but would still offer most of the advantages multi-axis technology has, especially when working on parts that require machining on multiple sides .

Key Differences Between 4-Axis and 5-Axis CNC Systems

The basic distinction between the 4- and the 5-axis CNC can be seen in the rotational axes numbers. An example of a 5-axis system is the 4-axis technique with a pair of axes as they allow the axes rotation along 2 axes at the same time unlike in the 4-axis technique where only one axis (usually A-axis) can give a rotation with the remaining staying fixed. This further freedom of degrees greatly increases the number of geometries that can be machined, including angled features, and the complexity of parts that can be manufactured in one setup.

The most notable distinction of the two systems are probably the accessibility that the 4-axis machines enjoy more so than the 5-axis machines. The 4-axis machines are easier to access four faces of a part, and should be used on prismatic components and cylindrical parts. Nevertheless, they still might need a multi-setup of a part part because of features at compound angles, or so far as they cannot be rotated by a single axis to reach into the part. The same is achievable with 5-axis systems which have probable access to nearly any surface of a part, thus removing the need of multiple set ups in most situations.

Throughput of complex parts that can be manufactured efficiently is also very different with 4-axis machines prepared to machine parts that are on multiple faces, can be accessed with one axis rotation, whereas 5-axis machines are best positioned to manufacture those parts that are geometrically demanding to a geometry and capable of undercuts, large pockets and features at compound angles that could never be possible with a 4-axis machine.

Another major difference is programming complexity. 4-axis programming, especially indexing operations, tends to be less complex, which is easier to learn and operate than 5-axis programming which needs more complex software and advanced user skills in order to deal with simultaneous operations in order to optimize the program and prevent collision.

Performance Comparison: Efficiency and Precision

In relation to performance of 4-axis and 5-axis CNC systems a number of dynamics are involved in the aspects of time of machining, quality of the surface machined, accuracy, and the level of efficiency. Going to 4-axis rather than 3-axis tends to save you more time simply because you would otherwise have to do more set ups. When we speak of 5-axis systems, this time savings is again accelerated because in certain parts 5-axis systems will be able to frequently perform the part in one single setup that would involve a multi-setup in a 4-axis machine.

Another aspect in which the two systems differ greatly is in surface quality. 5-axis machining centers frequently give much better surface to their workpiece because 5-axis machine tools can use the best cutting angles consistently all over the machining cycle. Capacity to tilt the cutting tool to the required angle in the surface can help in keeping the tool marks to a reasonable minimum and on the other hand increase the overall quality of the part. 4-axis requires minimal tool motions to make the surfaces it can reach in order to achieve great surface finishes, but additional finishing operations are likely needed to process inaccessible surfaces for the final machined part .

In typical systems, with appropriate calibration and maintenance, both accuracy and repeatability tends to be extremely good. 5-axis systems may however have the benefit of producing very tight tolerances over complicated geometries by virtue of the fact they can machine features in ideal positions. It is also less difficult to maintain tight tolerances on an entire 4 sides of a part because in 4-axis machining the piece remains in a one setup, thus reducing the chances of expensive quality assurance investigations. This advantage is increased in the 5-axis system where even more complicated characteristics can remain in one setup.

The sharpness of tools also is different in both systems. The 5-axis machines frequently can use shorter, stiffer cutting tools, since they are able to attack features on the most favorable angle, leading to improved tool life and cutting rates. 4-axis equipment provides some, but not all, of these benefits and may still need longer tools for cutting tool moving linearly to attack some features, which may constrain cutting parameters.

Cost Analysis: Investment and Operating Expenses

Financial impacts of the decision to utilize 4- and 5- axis CNC machines go beyond the cost of purchase to operating costs, and maintenance cost, and the ROI. Up-front cost of 5 axis machines is usually 50-100 percent higher than similar 4 axis machines due to the complexities of the mechanical system, control software, components of higher precision needed, and a few different arrangements used in their design.

The costs of operation between the 2 systems also vary with the 5-axis machines normally having to utilize a more advanced form of programming software which may be a considerable continuing cost. Also, 5-axis programming tends to require even more skilled operators, which can even make the labour more expensive. Nevertheless, the increased cost of operation is evened out with the increased productivity and set-up times of 5-axis systems.

Training costs are another factor that came to place. 4-axis systems are generally less expensive to train on and use compared to milling machines , and therefore will be easier taught to currently employed personnel with a 3-axis experience background. 5-axis machine training is more intensely complicated and expensive to train on and thus functions as an initial heavy investment in human assets.

The return on investment is closely determined by the kind of parts being produced and the output rates of the same. On high volume runs of complex components, a 5-axis machine can give shorter payback time even though the equipment is expensive to purchase. On the lower volume manufacture or components that do not need the full potential of 5-axes machining, 4-axes might prove to be financially more rewarding.

They also need to consider the maintenance cost in the total cost of ownership, 5-axis has more complex mechanisms and control system that could lead to high maintenance costs . Yet, most modern 5-axis machines tend to be quite reliable when regularly serviced and any productivity increases may end up being worth the cost increase of additional servicing, reducing the need for multiple setups .

Choosing the Right System for Your Manufacturing Needs

To make a decision on the 4-axis and 5-axis CNC systems, it is essential to study your manufacturing needs thoroughly in terms of budget, long-term production plans, etc. Part complexity, the level of production volumes, expertise available, and machining operations should be the determining factor in making the decision as opposed to the most sophisticated technology that one can use just because it is available cnc milling machines.

The initial step is the part geometry analysis in making this decision. It is a 4-axis system and can be the best option to machine your parts when most of them just need machining on 4 sides with features that can be accessed by rotating the workpiece on one axis. Elements in complex sculptured surfaces, deep cavities or elements that are compound angled are also to benefit with 5-axis capabilities z axis.

The factors in production volume are also essential in the decision-making aspect. The higher the volume of production, the greater the ability of a shop floor to absorb the extra cost of a 5-axis technology through efficiency gain and shortened cycle. We have found that 4-axis systems can be economically viable to use over low-volume, high-mix production environments even though they still hold substantial benefits relative to 3-axis machining.

Another vital consideration is the available knowledge in your organization. In case your crew is not very well experienced in multi-axis programming and usage, particularly with two axes rotation it will be more realistic to begin work with 4-axes system. The method enables you to create multi-axis experience through a process and still achieve great productivity outcomes.

Most of the manufacturers will end up basing their decision on budgetary requirements linear directions. Three axis milling machines can be fitted with either trunnions or rotary axis accessories that allow 4th and 5th axis milling. This modular system enables the manufacturers to begin in 3 axes system and purchase multi-axis capability when they are financially able.

Future Trends and Industry Applications

The multi-axis CNC machining field has been fast changing with the developing control technology, cutting tools, and the need the industry has to improve the level of complexity in each component. The modern CNC systems have become Industry 4.0 standard and their 4-axes and 5-axes machines have integrated with the IoT connectivity, predictive maintenance, and advanced process monitoring, which are crucial in moulding processes rotation axis .

Multi-axis machining is starting to be impacted by artificial intelligence and machine learning with automated optimization of the programming, predictive tool wear and adaptive machining tools. Such technologies are also automating the process of 5-axis machining by making it easier to program and ensuring that you do not need much expertise to operate it most effectively.

The usage of the industry applications is still growing even the manufacturing needs are becoming more stringent. The aerospace market is turning towards 5-axis machining in the advanced turbine parts and the structure components rotational axes. Implants, surgical and diagnostic devices all call on 4-axis and 5-axis use in medical device manufacturing. Electric and lightweight parts of vehicles are being implemented on automotive manufacturers using multi-axis technology planar compound angled features.

The integration of additive manufacturing involves the convergence of CNC machines with 3D printing capacities and this is an upcoming trend. Such a mixed solution can also use 5-axes to carry out the final finishing of additively manufactured components to provide the flexibility of the 3D printing design and finishing accuracy that are typical of CNC machining machine angled features.

Improved capabilities and efficiency of 4 and 5 axis systems are coming with the further evolution of cutting tool technology specifically designed to suit to multi-axis operations) art milling machines

. The more sophisticated coatings, optimized tool geometries and intelligent tool technologies are leading to an increase in cutting speeds and tool life in multi-axis use.

Conclusion

The decision made between 4-axis or 5-axis CNC machining systems will always be determined by your own manufacturing needs, budgetary requirements and the overall future manufacturing plans. 4-axis systems must be very carefully balanced in regard to capability versus the cost-effectiveness of parts that require access to multiple faces via single-axis rotational axis. These systems have great benefit compared to conventional 3-axis machining, and they are, comparatively, easy to program, and to train operators about.

The 5-axis systems are the most advanced form of CNC machining systems available today perhaps without comparison, in terms of flexibility to accommodate complex shapes and catching up complex parts in one-upset rotation axes

. Although the initial cost of investment and running expenses are more as compared to that of conventional method, the benefits attributed to enhanced productivity and enlarged capacity are many, including the ability to produce accurate planar milled profiles, and this justifies the extra cost to manufacturers making highly complex and high value parts.