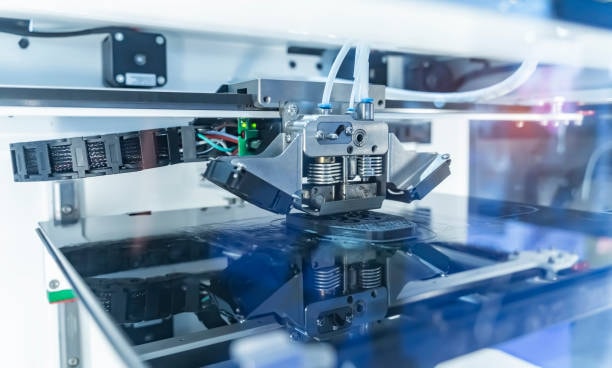

Learn about all the information regarding 3D printing and its plastics PLA, ABS, PETG, and more advanced material, as well as options that are available at low cost . Find out about materials, uses of materials, and best practice in good 3D printing outcomes powder form.

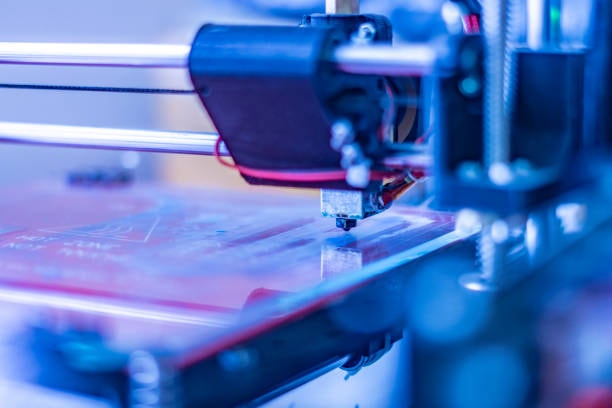

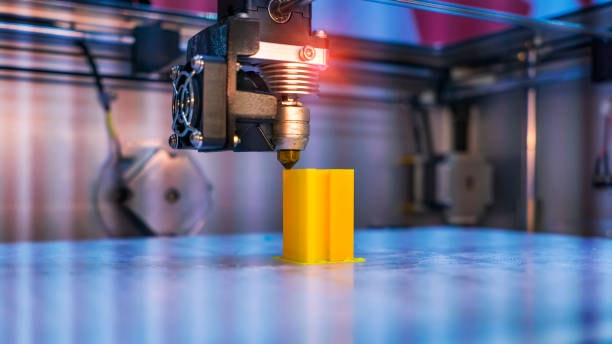

The 3D printing world has changed manufacturing, prototyping and creative design and plastic materials have been used as a foundation to this ground-breaking technology, unlike traditional manufacturing methods . Starting small with simple thermoplastics and continuing to the modern advanced-engineering-grade thermoplastics, the history of the 3D printing materials has unlocked the previously impossible doors of industries that use these materials, especially for functional prototypes. to the field of medicine, including the development of innovative medical devices market growth .

Knowledge of the various terrain of 3D printing pilled is important to everybody who wants to tap the full power of additive manufacturing, especially for industrial applications plastic filament

. Every material, especially those with lower density, has its own characteristics, processing specifications, and areas of utilization that can either complete or spoil the success of a project semi crystalline structures. The present guide offers an insight into the full range of plastic materials that can be used as 3D-printing, including common soluble filament materials which can be beneficial to a novice and an expert in this field major companies.

Understanding 3D Printing Plastics fiber reinforced materials: The Foundation of Additive Manufacturing

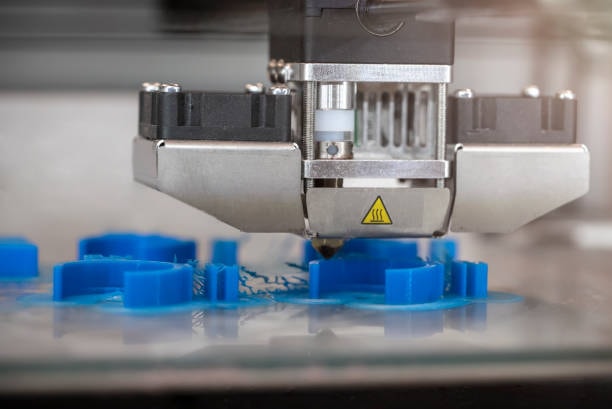

The plastics used in 3D printing are synthetics or semi-synthetics, having the characteristics of being impact resistant, malleable, and their moldability to be made under controlled conditions. Raw materials used in 3D printing are mainly thermoplastics, plastics that can repeatedly be heated and cooled without being damaged considerably, exhibiting good temperature resistance and suitable to the layer by layer construction process inherent in additive manufacturing.

The type of plastic used directly influences the mechanical characteristics of the end product, its cosmetics as well as functional abilities. The different 3D printing technologies need plastics in different forms e.g. Fused Deposition Modeling (FDM) systems use filament plastics, Selective Laser Sintering (SLS) systems use powdered plastics, Stereolithography (SLA) uses resins, all of which exhibit excellent mechanical properties . All these forms have some notable benefits and flaws that should be taken into account when selecting the material for functional prototypes and parts engineering resins thermal resistance.

The molecular structure of 3D printing plastics defines how they behave during the process and what are the properties in the end. Glass transition temperature, crystallinity, and molecular weight distribution are some of the factors that affect the behavior of the plastics with regard to given 3D printing usages. With this knowledge of the essential properties, including high performance polymers t is possible to choose material and optimization of printing parameters thermoplastic widely

..

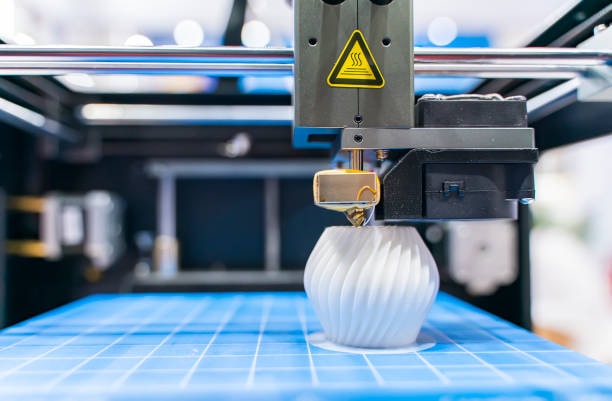

PLA: The Entry-Level Champion for 3D Printing

Polylactic Acid (PLA), often referred to as polylactic acid, has been able to achieve its status as the friendliest 3D printing plastic due to which it has become the 3D printing material of choice when amateurs and education is concerned. The material is made using biodegradable resources such as corn starch and sugarcane, which are renewable raw materials with strong mechanical properties , making it environmentally-friendly to the set sustainability objectives besides its high printability features similar properties.

PLA has a low processing temperature, usually between 190 o C and 230 o C and is therefore compatible with a vast majority of desktop 3D printers which do not need a special heating apparatus. This availability has added a huge part to the popularity of PLA in the maker community and learning institutions, despite not being able to withstand high temperatures . The low shrinkage of the material on cooling saves the requirement of heated build plates taking the process of printing to a simpler level with saving in equipment traditional methods.

The biodegradable characteristic of PLA differs with that of petroleum based plastic materials whereas the same factor is a disadvantage in some uses of these materials. Although the material suffers degradation in particular environments of composting, it does not undergo degradation under regular use conditions. With such a range of colors and finishes available in the form of transparent, metallic and wood filled PLA is a perfect choice for decorative objects as well as in prototype applications and decorations.

Nonetheless, PLA has a comparatively poor heat resistance and brittleness compared with other engineering plastics which makes this material non-functional in other applications that depend on durability or high temperature. The creeping characteristics of the material apply when in continuous loads and the material should be stored with sensitivity to wet conditions that must be considered during design and storage.

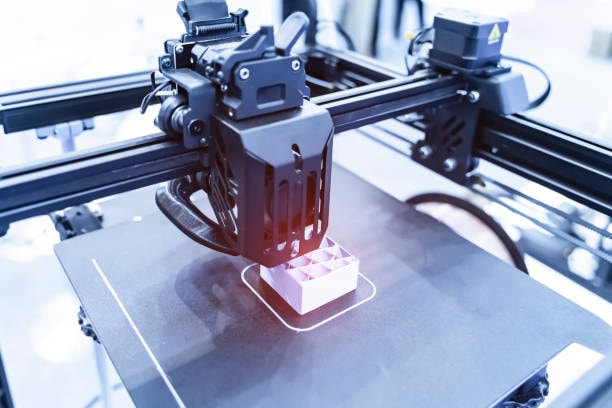

ABS: The Industrial Workhorse of 3D Printing

ABS (acrylonitrile butadiene styrene) is the industrial benchmark, when it comes to 3D printing technology, that involves the durability, impact and chemical stability of the products consumer goods. This thermoplastic, a petroleum product, has been in wide manufacturing use over the past decades and its use has been in areas as varied as automotive parts in the automotive sector and consumer electronics cases.

Superior mechanical properties of ABS, such as good impact resistance and flexibility are ideal and can be used as functional prototypes and end-use parts. This property allows the material to be used at temperatures up to 80 o C which increases its application to a wider range as compared to PLA. ABS is also very chemically resistant and sanding, drilling and smoothing with acetone vapour is very easy to carry out.

ABS needs a much tamer environment to process than PLA, with a range of temperatures in between 230 C and 250 C usually set on the printer and required build plates requiring heating to suppress warping. The propensity of this material to shrink when being cooled down and the release of fumes that are fairly toxic in the process of printing make such procedures to require proper ventilation and even enclosed printing booths.

There is added advantage to prototyping and manufacturing because ABS can be recycled and welded with chemical solvents such as acetone. But processing temperatures and fume fumes that are associated with the material are higher, so it takes more advanced equipment and care when printing in 3D than when using PLA.

PETG: Combining Strength with Ease of Use

Polysterene Terephthalate Glycol (PETG) has become an attraction of compromise between printability of PLA and strength of ABS. The glycol modified form of PET is great in terms of chemical resistance, optical clarity, and food safety description, hence applicable in various field settings, including polyethylene terephthalate. such as food containers and in medical sectors.

Printing properties of PETG are similar to PLA, and the processing temperatures vary in the range of 220 C to 250 C, and the warping is minimum. There is great layer adhesion and low shrink rate of the material that makes the printing results reliable whenever constructing complex geometries. When compared to PLA, PETG, which can be used to create prototypes, has natural strength and resistance to impact and it can be more easily processed than ABS.

PETG has a great chemical resistance, which fits best in such cases, as working with different chemicals, acids and bases. Its ability to be food-grade allows the possibility of kitchen uses, water bottles and food storage containers, thus addressing the growing demand for safe material . The recyclability of the material fits with the environmental sustainability objectives but allowing functionality delivering the characteristics of performance needed of such applications.

The transparency and optical clearness of PETG make it useful in situations that demand making internal component visual inspection or meet aesthetic needs. Nonetheless, the stringing property of the material during the printing process and the likelihood to get damaged by scratches will necessitate cautious parameter selection and manual operation measures.

ASA: UV-Resistant Alternative to ABS

Acrylonitrile Styrene Acrylate (ASA) is similar to ABS in its mechanical properties but has far better UV resistance and weatherability. It is this fact which makes ASA especially useful in outdoor use and in automotive hardware, where water resistance is crucial, which is subject to extended exposure to sunlight and other weather conditions.

ASA processing parameters are also very close to those of ABS and ASA also needs similar printing temperatures and environmental controls. This material has superior chemical corrosion resistance as well as impact strength which warrants using it in functional or long-lasting parts. The excellent UV stability offered by ASA eliminates degeneration and discoloration of parts of ABS in sunlight.

ASA has similar emission properties to ABS during printing and ventilation and ideally printing enclosures are needed. Disposal of material to warp when cooled means the heated build plates, and cooled at appropriate rates. Although it goes through these processing hurdles, the fact is that ASA has a higher environmental resistance, and so may be used in outdoor circumstances.

Such a property of ASA that allows it to keep its properties at a wide range of temperatures renders it appropriate in automotive industry, outdoor signs, and sports equipment. An excellent finish of the surface of the material and capacity to be post-processed using traditional techniques contribute to the attractiveness of the material to aesthetic uses where its adjacent durability is desired.

Polycarbonate: Engineering-Grade Strength and Clarity

Polycarbonate (PC) is one of the best-performance transparent plastics to 3D print. Its outstanding resistance to impact, optic brightness, and hot temperature make it irreplaceable in uses that need a combination of both tension and transparency uses like personal protectors, optics lens and white cavities.

Processing PC takes more compressing than typical 3D printing plastics, usually requiring a printing temperature greater than 280 o C, and often require heated chambers to avoid warping. Its ability to pick up moisture in the air needs special storage and even pre-printing drying techniques to obtain maximum effect, especially in conditions of high cooling .

The theoretical mechanical strength is outstanding and PC can resist impact many hundreds times that of ABS or PETG, meaning that PC is used in protective application and is suitable in high-stress components. The approximate glass transition temperature of the material of 150 o C can be applied in high temperature conditions where other plastics would not survive.

Optical proprieties of PC can be utilized in applications that conveniently need light transmission or visual inspection potential. But because of the sensitivity of the material to UV energy, it might yellow over time and this necessitates the consideration of UV stabilizers or coating to succeed with outdoor use. PC is more expensive and has more complex processing so its application is limited to those applications that need high performance polymers’ specific properties only.

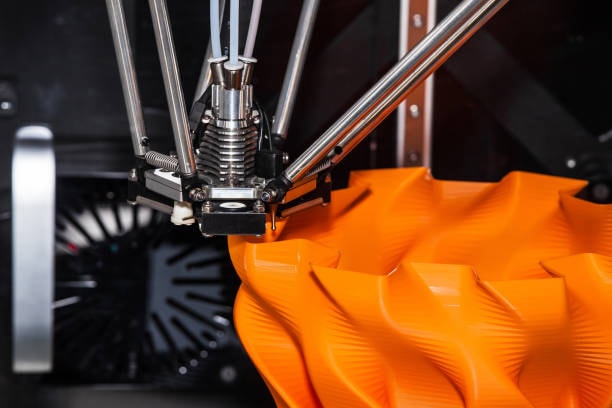

High-Performance Plastics: PEEK, PEKK, and ULTEM

The development in 3D printing technology has made possible the processing of high performance engineering plastics that are traditionally available to the injection molding and machining. Polymers such as Polyetheretherketone (PEEK), Polyetherketoneketone (PEKK) and Polyetherimide (ULTEM) have the density of metals but the weight, making them suitable for lightweight components .

Such high tech materials usually need special 3D printers with high extrusion temperatures, over 400 C, and heated chambers both during printing. These properties include high chemical resistance, high-temperature resistance and biocompatibility, which provides their value in aerospace, medical, and chemical processing applications.

The property combination of good chemical resistance, high-temperature behavior and biocompatibility of PEEK has made it of particular value in medical implants, and aerospace hardware. The capability of the material to retain properties up to temperatures of over 250 0 C makes it applicable in engine bays’ and in creating anatomical models chemical processing plant locations where conventional plastics would deteriorate.

The high-performance plastics require complexity of processing and also equipment, which makes them much more expensive than regular 3D-printing materials. Nevertheless, the freedom to create complex geometries with additive manufacturing that may be complex or not possible to manufacture conventionally tend to make it worth the investment, in case of specific applications.

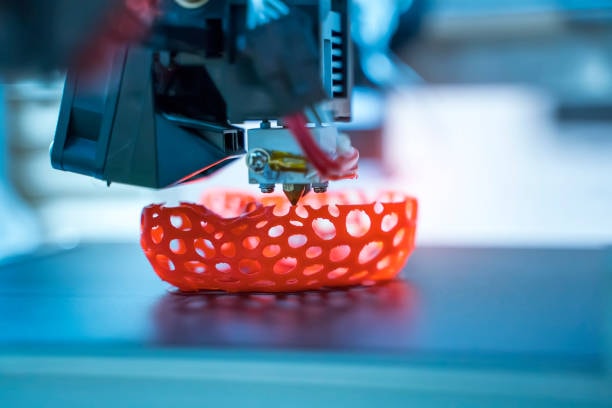

Composite Materials: Reinforced Plastics for Enhanced Performance

Reinforcing fibers added to 3D printing plastics have opened a world of new materials which have much better mechanical properties. The reinforcements of printed parts with carbon fiber, glass fiber, or aramid fiber have a potential to drastically enhance the strength-to-weight ratio with preserving the liberty of design intrinsic to additive manufacturing.

Short fiber reinforcements, usually chopped fibers with a length of less than one millimeter are directly added into the plastic matrix in the production of filament. The method offers enhanced rigidity and strength at compatibility levels with typical FDM printing devices, making it suitable for applications such as protective screens . The fibers random orientation grants the enhancement of isotropic properties over the printed component.

There is also the more recent continuous fiber reinforcement which uses unfragmented fibers impregnated in the plastic matrix during the printing process. Such a method demands specialised printing machineries that would work on both the reinforcing fibers and the plastic matrix in a single go. The produced components will be as strong as conventional composites have become with strength approaching comparable materials and are geometrically complex in the way 3D printing has enabled.

Processing challenges of composite materials are possible wear of the nozzle resulting in abrasivefibers and optimization of the printing parameters necessary to get good fiber-matrix adhesion. The anisotropic nature of continuous fiber reinforced components implies that much attention has to be paid to orientation of the fibers with respect to the anticipated loading scenario..

Flexible and Elastic Materials: TPU and TPE

Other advanced materials include Thermoplastic Polyurethane (TPU) and Thermoplastic Elastomers (TPE) which introduce rubber-like property to 3D printing, thus allowing the creation of flexible, stretchable as well as compressible parts. The applications that such materials open are in gaskets, seals, shock absorbers, and wearable devices where elasticity and flexibility are vital, especially when using dual extruder printers .

The physics of print on the flexible material offers special concerns over the printing parameters and equipment characteristics. These materials can be characterised by their elasticity which can lead to feeding problem in normal extruders and may need special feeding methods or extruder designs. The configuration of printing speed should usually be slowed down not to stretch materials and maintain continuous layers.

Flexible 3D printing materials have a hardness range that ranges anywhere between very soft rubber-like compounds to close to being as flexible as the traditional thermoplastics. With this spectrum, they can select material of preferred application need for soft protective covers, to semi-rigid living hinges.

The number of applications of flexible 3D printing materials is still growing because of the decreasing formulation of the material and increasing processing methods. Design optimization features enabling complex geometries to be designed with different levels of stiffness provide special opportunities to design products and customize them.

Soluble Support Materials: PVA and HIPS

The introduction of soluble support materials has completely changed the game of 3D printing since it is now possible tofabricate complex support structures with overhangs and internal holes that the traditional support materials could not support. The two major forms of soluble supports are the Polyvinyl Alcohol (PVA) and the High Impact Polystyrene (HIPS), both of which can be used alongside plastic powders with distinct benefits connected to the desired application.

The PVA is specifically user friendly on the account of the fact that the support structures can be dissolved in warm water. This property renders PVA to be appropriate as a result of the area concerned where chemical solvents are unwanted or unsuitable. The suitability of the material printed using dual-extrusion printers with PLA and PETG allows creating complex components with the minimum post-processing capabilities.

HIPS is a soluble support, combined with ABS and is dissolved in limonene-based solvents. Similar printing temperatures and thermal expansion properties of both HIPS and ABS guarantee high adhesion levels during printing and the ability to fully remove them through the ability of solvents to dissolve them. Such a blend is very useful in long-life functional components where ABS mechanical properties are important.

The choice of soluble support materials is based on the printing material intended major utilization in the powder segment. , preferred method of dissolution, as well as application demands. Factors to consider are the time of the dissolution, environmental effects of the solvents and the compatibility of the process with the down stream steps.

Specialty Materials: Wood-Filled and Metal-Filled Filaments

The aesthetic and functionality of 3D printing has been increased due to the development of specialty filaments that combine conventional thermoplastics with wood particles and metal powders, among other additives. These hybrid materials have the same processing done that the basic plastics have but also have the added values of appearance, feel, and performance.

The wood-filled filament is normally having PLA or ABS matrices and particles or fibers of wood. The parts resulting have the appearance of wood and can be further processed by sanding, staining and finishing like ordinary woodworking. Natural variations in the distributions of the wood particles generate some original aesthetic effects, impossible to recreate by traditional manufacturing technologies.

Metal filled filaments insert metal powders into filament such as copper, bronze, stainless steel or aluminum into the mixture of polymer. Although these materials are not as stunning as solid metals, they offer the metallic appearance along with comparison to the standard plastics that are increased in density. Finishing and its polishing as well as patination processes may attain a metallized appearance as well as the ability to produce realistic metal components.

Specialty filaments processing concerns are the possible wear of the nozzle caused by aggressive particles and the necessity of the optimized printing settings to reach particle distribution uniformity. Such materials have special characteristics which are important in decoration and prototyping, along with special functional components.

Material Selection Criteria for 3D Printing Applications

The choice of the right plastic to use in 3d printing applications should be taken with much discretion based on various issues such as the mechanical demands, environmental factors, attractiveness purposes and process issues. The material properties, complexity of processing, and the cost will have to be factored in along with the requisites of subsequent manufacturing in the decision matrix.

Mechanical property requirements such as tensile strength, impact resistance, flexural modulus, fatigue resistance have to be aligned to material capabilities. The environmental exposures like yerger training heat, chemical resistance, UV exposure, and humidity have a strong effect on the type of materials used. Material selections are further limited by the lifetime in the intended use and safety needs.

Processing factors involve printer compatibility, processing temperatures required, support material and post-processing ability. Lack of uniformity in required forms, colors and quantities of materials also influences the flexibility of design and scale of production. The costs should swing both the price of materials and the complexity of processing as well as the possible waste production.

Material selection has been made easy by the development of material databases and selection tools that help to make material selection easy, at the same time making sure that the important properties of materials are given due consideration. With the material selection computer-aided tools, candidate materials that meet particular requirements and constraints may be identified rapidly.

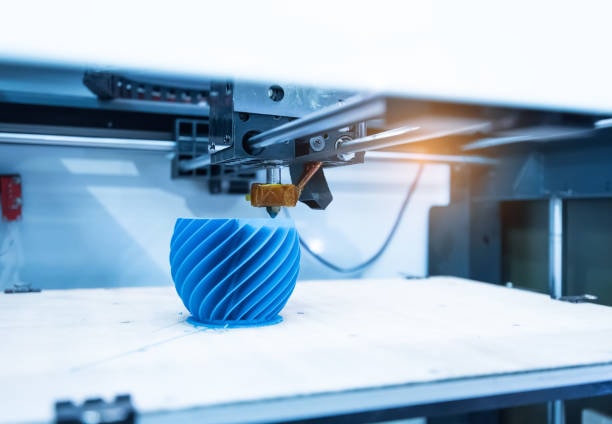

Processing Parameters and Optimization Techniques

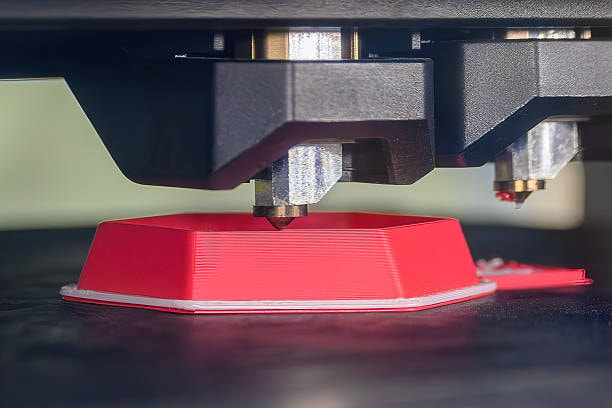

Effective 3-dimensional printing that uses plastic materials involves an optimal process parameter control such as the temperature process control, speed of printing, attachment of layers of printing and cooling process. Every material category offers particular processing issues which should be overcome by an optimization of the parameters and possibly the equipment, too.

Extruder temperature, heated bed temperature, and chamber temperature of enclosed systems fall under the heading of temperature control. The quality of material flow, layer adhesion, warpage and final part quality is impacted by the optimization of these parameters. Differential shrinkage and dimensional accuracy can also be faulted on temperature gradients in the printing environment.

Printing speed influences the behavior of the material flow, bonding of layers and the quality of surface finishing. Higher speeds can be used leading to under-extrusion or under-adhesions among layers whereas slower too fast can result in degradation of the material and surface defects. Printing speed improvement should take into account material rheology, geometry of parts and quality requirements.

Layer adhesion optimization Layer adhesion optimization is the process of balancing the printing temperature, layer height and how much material flows to obtain good inter-layer bonding and good dimensional accuracy. The performance of the material and improving the properties of the material can continue with post-processing methods of annealing, stress relief, and surface treatment.

Quality Control and Testing Methods

To maintain quality of 3D printed plastic components, vigorous testing and quality assurance process are mandatory. The funtions of characterizing materials, validating processes and inspection routines on the part side of things should be conducted to uphold the quality standard and ways of eliminating future hitch before it can hit production.

The characterization of the material is done by testing materials brought in under various factors including moisture content, molecular weight distribution, thermal properties, and level of contamination. Materials may also experience batch-to-batch variation in the mechanical properties which may drastically impact printing outcomes and end performance parts. Quality ought to be maintained through the appropriate procedure of material storage and handling.

Such process validation involves setting the process controls and observation of significant process parameters, documentation of equipment-based performance, and use of the statistical control of the processes. Calibration of printing devices and frequent control of environmental environment allows to achieve a stable processing regime.

The inspection of parts must entail dimensional measurements, surface inspection, and also mechanical property. The methods of non-destructive testing can detect the defects, including visual inspection, dimensional test, ultrasonic, without any effect on the integrity of parts.

Environmental Considerations and Sustainability

The environmental consequences of 3D printing plastics include its supplier, its processing energy, the waste byproduct, and the end disposition. Eco-friendly material choice and processing is also becoming more relevant since additive manufacturing becomes more production enable due to increasing demand .

Plastic made of plants, including PLA, is more environmentally friendly than petroleum-based ones, although their ability to biodegrade is conditioned on certain composting circumstances. The energy needs of processing various materials also differ greatly, especially with the increasing demand for high-performance plastics using much more energy compared with the typical thermoplastics.

Reduction strategies apply to waste by, e.g., optimizing support structures, recycling failed prints and support materials and designing closed-loop material systems. The possibility to recycle quite a number of plastics used in 3D printing in terms of shredding and re-pelletizing can result in a considerable decrease in human waste.

The process of creating sustainable material substitutes is still ongoing, and new bio-based applications and recycled content materials appear into the market quite often. Life cycle assessment tools aid in measurement of the effect of various materials selection and processing strategies on the environment.

Future Trends in 3D Printing Plastics

Dimensional printing of plastics can be called the future of the plastics field because it promises constant inventions on the capabilities of the materials and its capacity to be processed into even better processes. The latest developments in material formulations are both eliminating the existing constraints and creating new openings into the application scenarios of additive manufacturing.

Shape memory, self-healing, conductive Smart materials are an up-and-coming growth area, adding functionality to a 3D printed part. Such materials are able to vary properties based on environmental triggering, or conduct some active task like support, that was once considered a passive structural role.

Better processing techniques such as multi-material printing, the ability to control gradients in properties and in-situ property modification is making it possible to make parts with locally optimized properties. The developments diminish the assembly requirement and allow the production of the parts, which have a functional adjusted property.

Innovation of new materials and processes is being promoted with the incorporation of artificial intelligence and machine learning in material selectivity and its optimization in the processing route. Automated parameter optimization and predictive modeling is making it less time consuming and less expertise necessary to get 3D printing on challenging materials.

Applications Across Industries

Versatility of 3D printing plastics has contributed to their usage by many industries each having different necessities and challenges. The application knowledge related to the industry will aid the selection of the material and its processing under a targeted application.

Both aerospace uses are associated with the requirement of high strength to weight ratios, ability to withstand extreme temperatures and chemical compatibilities. PEEK and carbon fiber composite materials, and others, are advanced materials that allow flight-ready component production via additive manufacturing. An important benefit of the capability of forming intricate internal geometries and topology optimized structures is an ability to go beyond the capabilities of traditional manufacturing techniques.

The biocompatible materials should have proper mechanical property and resistance to sterilization to be used in medical applications. Individual implants and surgical guides manufactured with 3D printing perform better by ensuring customization to the patient. Novel treatment methods are being made possible using novel materials, including medical-grade PEEK and biodegradable polymers.

Motor applications emphasize on lightweight and high-quality mechanical property and temperature resistant components. 3D printing with its rapid prototyping abilities quickens product development at the same time as making it possible to produce low-volume special products. Primarily, this would be utilized in end-use applications, where interior parts, under-hood parts and structural parts are designed to be made of lightweight materials.

Cost Analysis and Economic Considerations

Economics of 3D printing plastics can be considered to take into account various elements like the cost of material, time of processing, the need of equipment as well as post-processing activities. The observation of such cost drivers allows making appropriate decisions concerning the choice of materials and process improvements.

The material costs differ greatly depending on the type of plastic whereas special plastics and high performance plastics fetch higher cost. The effective cost per part is a factor of the efficiency of the different materials that are used, same materials with low waste pellets generate more yield at an increased unit cost.

The costs of processing encompass the functioning of equipment, energy utilization and the labor demands. Complex materials that need special equipment or long processing process contribute to the total cost per part. Scalability and labor cost is influenced by the automation potential of the various materials and processes.

Specifications that augment the total cost of the part during post-processing such as removal of support materials, finishing and part inspection are also required. The materials which allow less post-processing could give cost benefits even when the materials are more expensive. Trade offs between the selection of materials and processing needs should to be worked out carefully.

Troubleshooting Common Issues

To have successful 3D printing using plastic materials, it is important to understand and tackle the problems which are associated with a common processing. Methods of problem identification and their solutions serve to ensure equal quality and minimize the amounts of wastes generated.

Thermal stress during cool down or lack of bed adhesion often leads to warping problems and dimensional distortion. Abatement measures are improvement of bed temperature, application of suitable bed adhesion aid, and cooling rate control using environmental control or design of parts.

When the adhesion of layers is incorrect, it may have occurred due to improper processing temperature, polluted material or poor surface preparation. Troubleshooting refers to careful judgment of the temperature, material status and aspects regarding the printing environment.

Some surface quality problems such as layer lines, stringing, and roughness will be solved by optimizing the parameters, choosing the right material and post processing. Through this relationship between surface quality and processing parameters, it is more possible to make specific improvements.

Safety Considerations and Best Practices

The 3D printing plastic activity needs to consider matters like proper handling, dust and fume inhalation and fire hazards. The appropriate safety conditions provide secure procedures to the personnel, the machine and provide similar processing outputs.

The safety aspects of material handling entails the condition of storage, individual protective gear, and material related danger understanding. Skins Irritation and respiratory problems may be some of the effects of materials to deal with during handling and processing correctly.

The fume exposure issues are of special concern to those materials which produce potentially hazardous compounds as they are processed. Through proper ventilation system and closed printing chambers, exposure risks are reduced. The behavior of specific emissions of each material can be understood; thus, these measures should be taken accordingly.

Fire safety aspects involve use of adequate electrical equipment, storage of materials and emergency response strategies. The fire safety measures must be taken seriously due to the combustibility nature of various materials used as well as the existence of hot elements.

Conclusion

The scene of 3D printing plastics is a wonderful upward integration of material science, manufacturing technology and design innovation. Whether it is the accessibility of PLA as an educational tool or the highest performance capabilities of PEEK as aerospace parts, every material has its own, distinct benefits that allow new capabilities of additive manufacturing.

3D printing plastics are still evolving to open more possibilities to 3D printing. The line between prototyping applications and production applications is also disappearing as materials grow more and more advanced and processing technologies are upgraded and can support new business models and production processes.

The key to success in 3D printing of plastic materials is based on awareness of the fundamental properties of various materials, maximization of processing parameters to suit an application and systematic emphasis on quality and safety in the manufacturing process. The material and processing expertise gained in the investment results in material in a higher part quality, less generation of waste, and expanded applications opportunities, allowing manufacturers to operate cost effectively .