Meta Description: Learn about the common 3d printing file formats, including the standard tessellation language, and the key 3D printer files used in the contemporary manufacturing. Get familiar with STL, OBJ, G-code, 3MF, and more about the formats that are essential to the completion of successful printing projects and the international delivery.

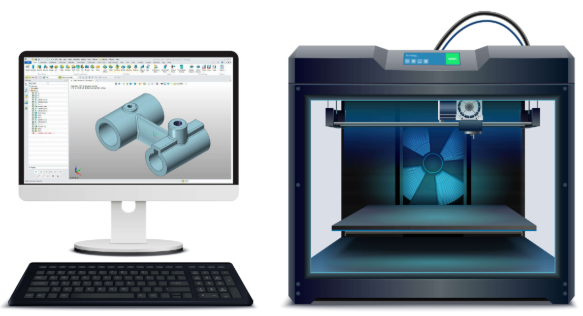

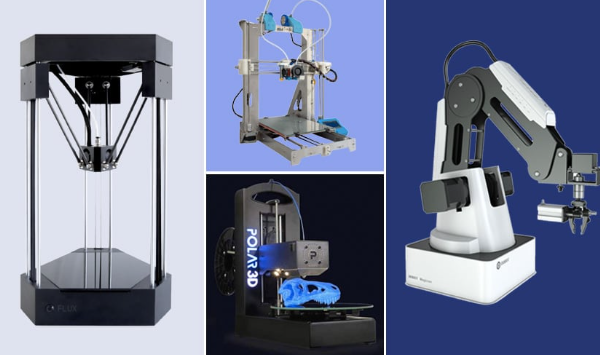

After the development of the three-dimensional printer, manufacturing within the industry was never the same due to the revolution it brought about whether in the prototyping stage or in full production. A key component behind this technology, especially in computer aided design, can be seen as a wide range of different file formats, every one of which has its own purpose in the 3D printing process STL, OBJ, AMF, and 3MF. The various businesses that are involved in global manufacturing and logistics find it very important in effectively operating it, monitoring its quality and smoothness in carrying out the international shipping procedures when they know very well about these file types universal compatibility.

GWT Worldwide is a professional logistics services provider specialised in global freight forwarding, supply chain solution and we strongly realise the great significance of the knowledge of 3D printing file formats to our clients engaging in cross country manufacturing outfits as well as e-commerce. The amount of international shipping, customs clearance, and Amazon FBA logistics in our arsenal makes us most qualified to help a company make its way through an unfamiliar system of 3D printed physical object transportation..

What Are 3D Printer File Types and Why Do They Matter?

Digital formats that carry the description of the information that will result in the manufacture of a three dimensional object via the process of additive manufacturing through 3D printer is referred to as 3D printer file types. These files, which include surface geometry, are the medium of communication between the concept of digital design and reality of physical manufacturing. All the formats contain certain information of the types of the data, starting with the simple geometrical data and ending with the complicated data about the material properties, colors and the manufacturing factors.

The awareness of these types of files is especially relevant to the scenario of manufacturing across the world where a design developed in the first country should be produced in the second country. The quality of the 3d printing production, the time taken in the manufacturing process as well as the eventual logistics chain which markets products may be severely affected by the selection of the file format.

The Evolution of 3D File Formats in Manufacturing and the different file formats

3D printing file format development has been the parallel of the advancement in 3D printing technology itself. The earliest formats were concerned mostly with simple geometric representation whereas state of the art formats such as g code are used to store complex data regarding multiple materials, colors, textures and parameters of manufacturing cad program.

Such evolution is due to the increased complexity level of the target applications of 3D printing, which implies simple prototyping and end-use products with strict requirements in terms of specifications to be distributed internationally detailed textures. The producers and transport companies have to keep themselves up to date with these changes in order to retain competitive advantages in the world market.

STL Files: The Universal Language of 3D Printing

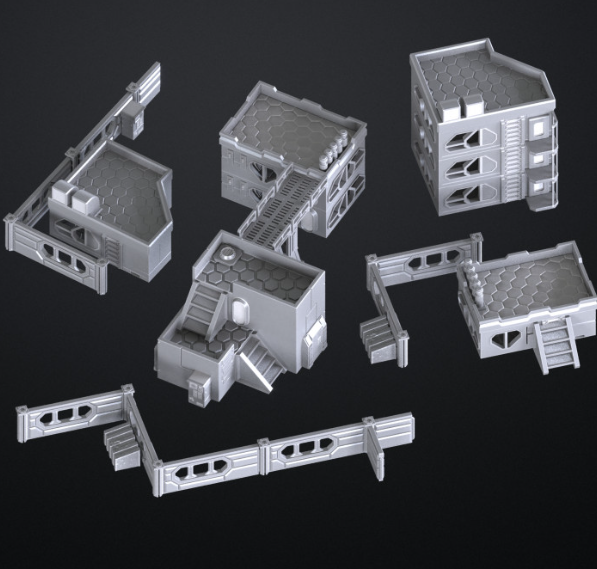

STL files, specifically the stl file format, are the most common file in 3D printing, based on the STereoLithography or 3D printing process invented by Chuck Hull in the 1980s. Such files include geometry data of a scenery and texture data on the surface of a virtual object in 3D without extra features such as color or material description rapid prototyping.

International manufacturing activity has no alternative but to rely on the STL format which is everywhere in use. When transporting 3D printed goods across the world, using the right format such as STL files and the obj file format guarantee that the goods can be compatible in other production and inspection units testing materials. Their disadvantage is, however, that stl files only work with geometric data and in many cases supplemental documentation is needed to specify the full manufacturing requirements physical form.

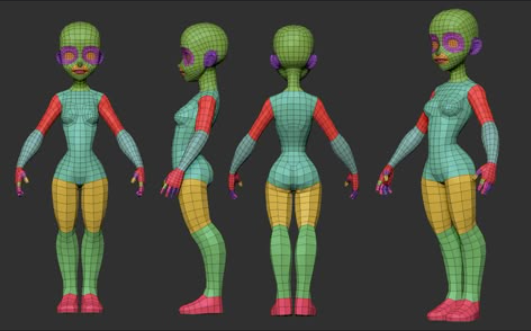

OBJ Files: Bridging Design and Colored Manufacturing

The Wavefront technologies developed the extension of the OBJ file which can be regarded as a favorite file format on the colored 3D printers various formats. These files consist of quality geometry, textures, and fully color data, and thus are priceless when it comes to products using the 3d printing file that have to match any color due to the existence of multiple international manufacturing locations default settings.

OBJ files would facilitate the required level of information needed to ensure the quality of the products in the shipping and customs procedures in cases where the logistics providers deal with consumer products hence, it has limited aesthetic requirements. The popularity of the obj file format as output files format with software used in design makes it especially useful in international supply chains.

G-Code: The Manufacturing Instruction Set

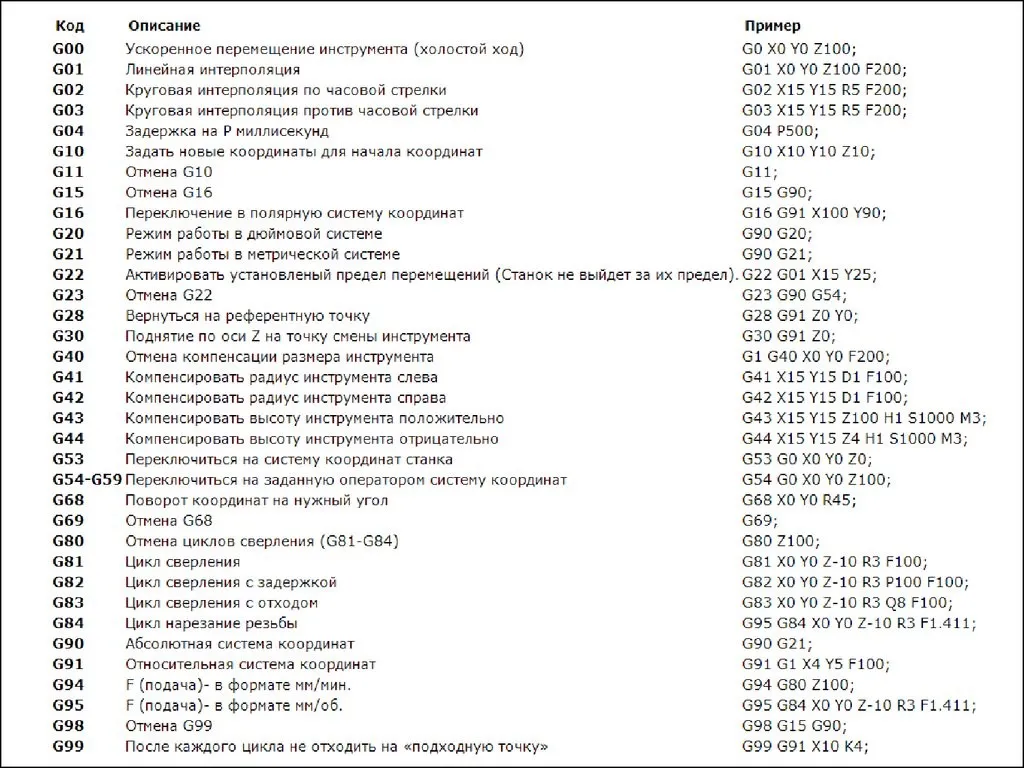

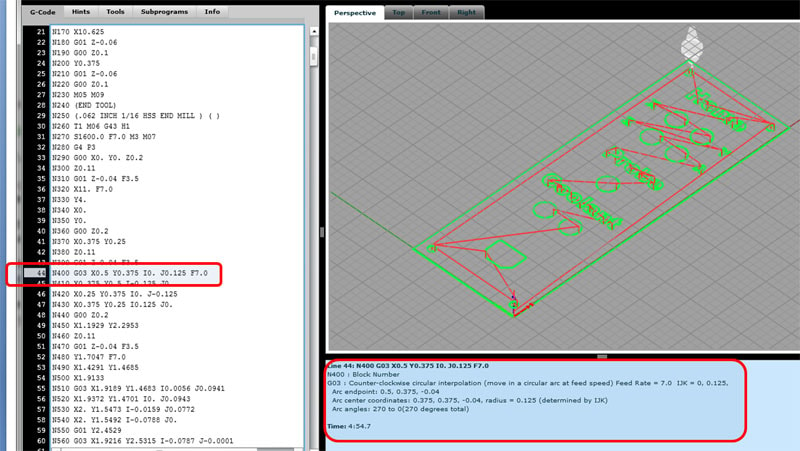

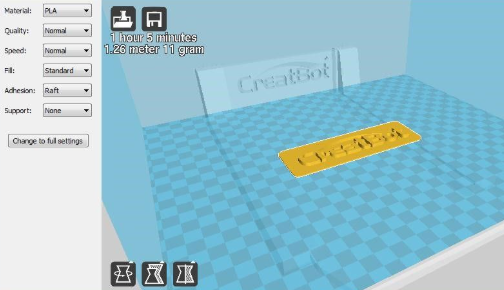

G-code files form the fundamental set of instructions to practically all computer-aided manufacturing devices and are the language of operations of the majority of 3D printers software tools. Such g code file have particular movement related codes that are interpreted by 3D printers to produce actual objects.

The knowledge of G-code plays a significant role in arranging production in several establishments in different countries. Manufacturers of different printers might need different variations of G-codes, which can hurt the production schedule and quality unification in international manufacturing processes.

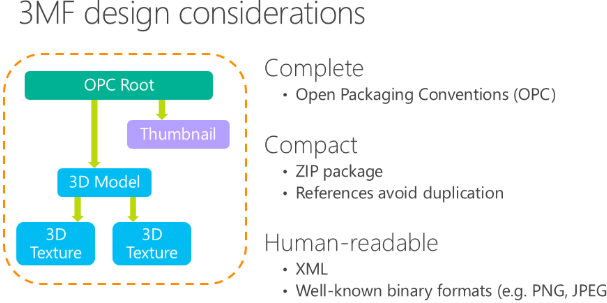

3MF Format: The Next Generation Standard

3MF format, known as an additive manufacturing file format, is a 3D XML-that was designed specifically with additive manufacturing in mind and includes definitions of the colors, material and the exact shapes that are not provided in STL files stanford triangle format. This stl format has the backing of major players in the industry such as Autodesk, Microsoft, HP, and other animation software developers.

In the case of manufacturing activities abroad, 3MF files ensure that sufficient information is delivered which minimizes miscommunication among design entities, manufacturing industries, and logistics companies. Such standardization of 3d printer file formats proves especially useful in the case of complex supply chains that involve different countries and regulatory regimes.

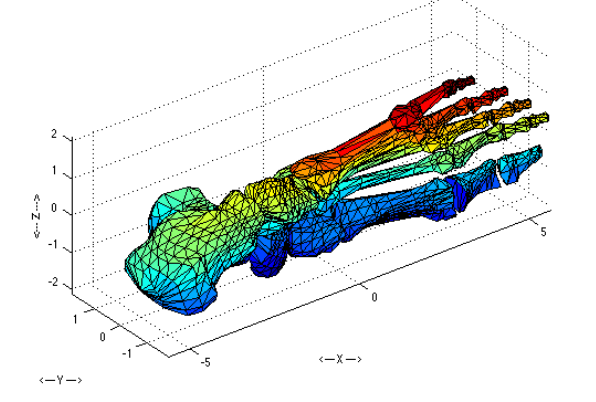

PLY Files: Capturing Real-World Data

The original intent of PLY format was to store shape and color data originating in 3D scanners by adding more attributes than STL (i.e., color, transparency-related data and texture information). This form is especially useful in reverse engineering applications or quality control applications.

In global logistics, PLY files are used in assisting a quality assurance procedure where scanned information on the products made will be matched against the original documents. This scale information is necessary in ensuring consistency of the global manufacturing networks.

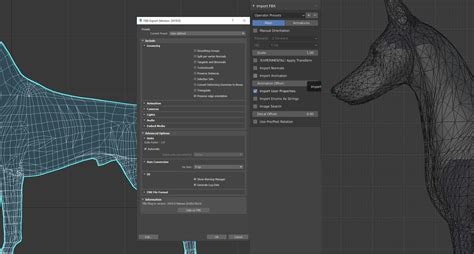

FBX Files: Animation and Complex Geometries

FBX is a 3D geometry exchange, animation interchange format, especially strong in Augmented and Virtual Reality. Although not universally supported by slicer software model file, FBX files have extensive data on animation and modeling.

Fan-based assemblies or manufacturers that manufacture products or hardware that has moving parts access detailed design data in FBX files. Nevertheless, before manufacturing the conversion to the proprietary format or more compatible formats is usually necessary, creating additional steps in production process.

X3G Files: Proprietary Manufacturing Solutions

X3G format is the native format of MakerBot, and is often used together with their PRINT software in slicing, editing, and preparing their builds. This proprietary format is incompatible but maximally performs with particular models of the hardware, especially considering large file sizes obj format.

When planning out the international production and logistics processes, companies that employ MakerBot systems in their manufacturing processes in various global locations have to take X3G format into consideration. Proprietary aspects may pose issue in multi-vendor manufacturing.

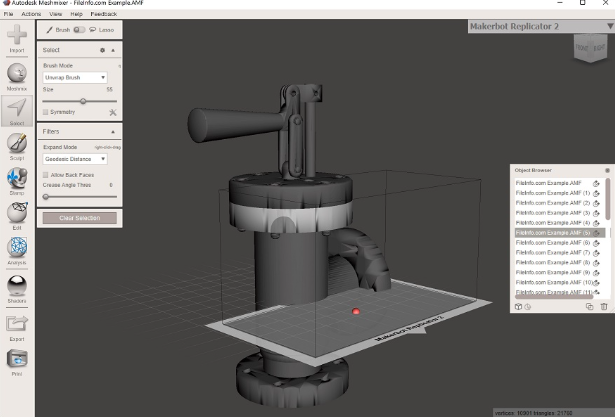

AMF Files: Addressing STL Limitations

In 2011 a new format was proposed as an ASTM standard, the Additive Manufacturing File, supporting color, material, multiple copies, and orientation and eliminating many geometric problems found in STL files. The great development of comprehensive 3D printing file standards is AMF detailed attributes.

ATM quality-sensitive applications, used in cross-border production, benefit by being able to use the amf file format to specify the specific product requirements in a lot of detail: the same specifications are used in a variety of production lines and multiple regulatory environments.

VRML Files: Virtual Reality Integration

VRML (Virtual Reality Modeling Language) is a widely supported format to render VR environments and objects, and compatible with slicer software. It is a universally supported text based format that has the vertices, edges, colors, textures and material properties.

VRML files are useful in the international manufacturing companies to represent the quality parameters of visualizing the complex products because of their comprehensive compatibility in the printing process most common file formats complex models.

File Format Selection for International Manufacturing

The selection of the right 3d printer file formats to be used in global manufacturing activities depends on several factors such as compatibilities to different printers design complicatedness, quality assurance and legal compliances. Various regions might prefer certain formats due to their usage of popular hardware and software ecosystems.

Those are the regional preferences that logistics providers need to know as it would allow them to streamline shipping routes, customs forms, and delivery times several different file formats. Straightforward manufacturing schedules and, thereby, global delivery windows may be affected by the decision of file format.

Quality Control and File Format Standards

Standardized protocols of file formats are necessary to ensure uniformity of quality under international machinery networks store data. Different formats contain less or more details regarding dimensional tolerance, surface finish, and property of materials needed during quality assurance animation data.

When it comes to planning with different time zones and legislative frameworks, creating a standard on the file format produced will be especially necessary when dealing with design department, manufacturing plant, and logistics companies cad software.

Digital Workflow Integration in Global Supply Chains

The contemporary 3D printing workflows combine several files formats in all phases of production, including design to end-manufacture. Knowledge of the interaction of various forms in these processes allows optimizing global supply chains management slicing software.

Digital workflow optimization can also contribute to a considerable level of lead time shortening in international manufacturing by providing precise instructions for planning logistics and service for customers in multiple markets more responsibly polygon file format.

Conversion Between File Formats

File format conversion features allow user flexibility when performing global manufacturing functions where or across several facilities where there may be diversities in software settlements. Knowledge of conversion operations and possible losses of information allow preserving design integrity in an international production network.

As international manufacturing systems generate vast volumes of items that require constant efficiency without compromising the accuracy of their designs, etc, automated conversion tools and quality checking standards become crucial.

Security Considerations for 3D File Formats

When exchanging 3D files in the transnational manufacturing networks, intellectual property protection is very important. Various file formats have varied degrees of security as well as access control and will alter the protection of the designs when distributed across the globe.

Current knowledge on security implication of various file formats will help an organization to establish proper protocols of exercising ownership of proprietary designs without interfering with effective manufacturing operations through international countries.

Regulatory Compliance and File Documentation

Manufacturing that is international must also take into consideration the regulatory restraints that can demand specific file format or documentation standards. The countries can be different in demand of technical documentation which is attached with manufactured products.

To facilitate 3D printed products shipping while accounting for large file sizes , it is necessary to consider these regulatory implications so that the logistics providers can engage in the right customs documentation and international shipping guidelines and regulations.

Future Trends in 3D File Formats

The constant advances in the 3D printing technology are still powering the growth of new file formats capable of greater material, multi-color printing, integration of electronics capabilities. Being up to date with each of these advancements will guarantee competitive edge in manufacturing markets all around the world.

New standards can affect the work of international logistics by altering the compatibility needs, quality checks, and regulations compliance levels within various markets.

Best Practices for File Management in Global Operations

With efficiency file management protocols, the international manufacturing behavior is met with consistency and quality. This consists of version control and access management, as well as quality assurance processes to assure integrity of the design within supply chains all around the world, especially when integrating with cad software .

Particularly important is the use of powerful file management systems in organizations with the operation in multiple countries having different technical standards and regulations.

Technology Integration and Automation

Automated file processing, quality check and production scheduling systems are more and more being used to form part of advanced manufacturing operations. Knowledge of the interaction between various file formats with the automated systems would make the global manufacturing processes more efficient.

Automation features can make a major difference in consistency and error reduction on the international manufacturing stage, which is likely to make logistics processes more predictive and bring sheer increase in customer satisfaction rates due to access to the global markets.

Conclusion

The variation in ecosystem of the 3D printer file formats is at the cornerstone of the contemporary manufacturing and global logistics operation. The universal existing STL files compatibility and the convenience of the full 3MF format specification are only the first two examples of how each file can be used in the manufacturing process across the globe. Knowing these structures enables one to wiser decisions when it has to do with production planning, quality control and logistical coordination within international markets. With improvement in 3D printing technology, it is important now more than ever to keep up with developments in file formats so as to achieve global competitive advantages in manufacturing and logistic operations.