Find out all about the Swiss machining – CNC turning methods and advanced manufacturing processes. Find out why the Swiss-type lathes feature in the leading industries in which high-precision components are manufactured.

Swiss machining is the most accurate manufacturing process with unparalleled precision and operational capacity to manufacture delicate and high-tolerance parts. Such an advanced technique of manufacturing has transformed industries in terms of the aerospace industry and medical device manufacturing sectors, whose manufacturing accuracy is crucial for high volume production, and not only desirable but mandatory.

As a professional provider of logistics services and a leading exponent of global forwarding and supply chain services, GWT Worldwide has developed an appreciation of precision manufacturing in international trade. With our extensive logistics services by air, by sea, on China-Europe railway, and through customs, precision manufactured components arrive safe and sound and on-time through the markets of the world.

What is Swiss Machining and How Does It Work?

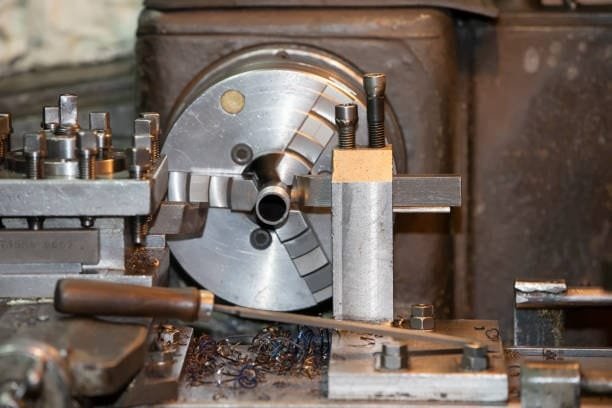

Swiss machining (sometimes called Swiss-type turning and in some circles sliding headstock machining ) is a type of high precision manufacturing where specially designed, computer numerically controlled lathes are used to create exceptionally precise and accurate cylindrical components. Uniqueness in workpiece support and positioning of cutting tools is the hallmark of Swiss machining.

Distinctive of Swiss machine tools is that the cutting tool is moved against a fixed workpiece (instead of vice versa, as in conventional lathes), and that the work is fed between the workpiece and a bar guide bushing by a sliding headstock mechanism. This guide bushing offers some much needed support immediately in the rear of the area of cutting, cutting down deflection and vibration during the process of machining by a dramatic extent.

Swiss machining process starts with the material, which is in the form of a bar stock generally with a diameter of 3mm-42mm, that is fed inside the headstock of the machine. There are several cutting tools that work concurrently operating different functions such as turning, drilling, cutting and threading as the material rotates. This multi-tasking ability also gives the ability to produce parts completely in one set up and it will not demand second operations of manufacture, making it ideal for high volume production runs .

Swiss machining allows very high levels of precision, often up to a tolerance of +/- 0.0002 inches (0.005mm) is routinely achieved. Such accuracy can be achieved because of the straight support of the guide bushing system and the capability of the machine to undertake several operations without realigning the workpiece, ensuring the production of precise parts .

Key Advantages of Swiss-Type CNC Lathes

The Swiss-type CNC lathes are beneficial in many ways such that their effectiveness cannot be done away with in precision manufacturing works. High accuracy and repeatability, provided by the exclusive guide bushing system as well as by the direct support of the workpiece near the cut, is the main advantage.

Another major plus point is speed and efficiency. Swiss machines are capable of completing many the processes in one go which drastically decrease the actual cycle times when measured against the traditional machining method. Where a conventional lathe may need multiple setups and operations to make a complex part, Swiss machine tool may in many cases make the same part, in one, continuous workpiece.

It is also useful to be able to handle long narrow pieces without any tendency to deflection. When parts are to be machined by using normal machining technique and have high length-diameter ratios, the outcome usually has chatter, lacks surface finish and also lacks accuracy. Swiss machines address both of those issues by creating these difficult geometries correctly over and over.

There is also automation capabilities to increase productivity. Most Swiss machines have bar feeders which are automatic; this means that it is possible to have light-out production runs that may last days or even hours in a row. Such automation helps to save the cost of labor and overall equipment effectiveness is improved.

Swiss machining always leads to quality in chances of the surface finish. The excellent finish is due to the stable cutting conditions and the tool can be controlled to give accurate results, usually the finishing operations done during secondary processes are unnecessary. This is especially essential when one needs to have strict aesthetic or functional needs of the components.

Essential Components and Features of Swiss Machines

Swiss machines have a number of specialized parts that allow their precision and multifunctionality. Most noticeable is the sliding headstock, which enables the bar stock to be fed into the machine so that it is continuously supported all the time through the guide bushing.

The guide bushing system plays the very important role of securing the stability of workpieces. This component supports in the radial direction up to 1-3mm away from the cutting zone and this virtually removes deflection even on long, slender parts. The guide bushing should be accurately made and well maintained so that to give the best performance.

There are several tooling positions which facilitate concurring machining activities. The majority of the Swiss machines are characterized by the front and the back working station in terms of tool, and the more other sophisticated machines have 40 or more tool positions. It can perform multi-tasked so that complex components can be done in one pass.

Another feature which is so important to many of the Swiss machines is the sub-spindle. This meaning the auxiliary spindle is able to retrieve partially finished parts, off the main spindle, allowing back-side machining to take place, without the need to have human hands make contact with the part. The latter is needed to create complicated components with features on both sides.

The ability on y-axis has become quite widespread in contemporary Swiss machines. This extra moving axis permits off-center drilling, milling and other processes and procedures that cannot be possible with the previous turning-only actions. The y-axis greatly increases the parts which can be manufactured on Swiss machines.

All these aspects are intelligently combined into advanced control systems. The latest Swiss machines have highly complex and advanced CNC controls capable of coordinating movements of multiple spindles, tool stations and axes, thereby providing the best efficiency and quality.

Materials Best Suited for Swiss Machining

Swiss machining works well with plenty of materials, however, there are several that are especially compatible to it. The material selected has a major influence on machining parameter, selecting tools, and part quality.

Common Swiss-machined grades are stainless steel, 303 and 316 and 17-4 PH. The guide bushing system allows these materials to achieve good surface finishes and tolerance as cutting conditions remain constant. This capability to provide constant cutting forces comes in handy most especially during the machining of work-hardening stainless steel alloys.

Aluminum alloys Swiss machining is an easy task because of the property of excellent machinability and being a lightweight material. High speed of Swiss machines comes in handy especially during machining of aluminum where they give a high material removal rate as well as precision. Aluminum typical grades are 6061, 7075 and 2024.

The Brass and other copper alloys work exceptionally well on the swiss types of machines. The quality of machinability of these materials and the accuracy of the swiss machine make them very desirable precision components in electronic, plumbing, and automotive products.

The titanium alloys are a bit hard to machine, but they can be processed effectively through the use of the Swiss machines with the right methods applied. Overall titanium components used in the aerospace industry or in medicine are produced using Swiss machines because of the stable cutting environment and potential to use specialized tooling.

Swiss equipment is also used to machine such plastics as engineering plastics (such as PEEK, Delrin, and nylon). The accuracy and surface finishes of the Swiss machines are good reasons, why they should be used in manufacturing plastic parts that need high level of tolerances and quality of surface finishing.

Swiss equipment can successfully be used to machine carbon steels and alloy steels, however, the selection of tools and the parameters of cut have to be optimized. The fact that it can produce the same cutting conditions on a consistent basis is of most advantage during the machining of such items.

Industries and Applications Driving Swiss Machining Demand

Aerospace is the industry that has one of the biggest markets of Swiss machining services. The strict tolerances, dependability and material characteristics needed in aerospace applications make Swiss machining a perfect solution to manufacturing. Parts like fuel system connectors, hydraulic connector and sensor housings need the high precision Swiss machines have to offer.

The use of Swiss machining is vital in the manufacturing of medical devices particularly those parts needed to manufacture important components. The surgical tools, implants and parts of the diagnostic machines should be of high quality and have high level of biocompatibility. These life critical applications, especially when dealing with small parts, require the precision and surface finish of the Swiss machines.

In the automotive business, Swiss machining is used to make high-precision parts such as fuel injection, parts and transmission parts, and sensor housings. The industry needs of cost effective, quality and high production machinery suits the Swiss machining industry.

Swiss machining produces small, exact, parts like connector pins, component of switching and choice parts, used by electronics manufacturing. In the miniaturization trend in electronics, it demands the extremely high-quality standards which the Swiss machinery provides.

The defense industry and the military demand quality and high performance in the component. Because of its deep hole drilling and drilling of exotic materials and because of its tight tolerances Swiss machining becomes useful in the production of weapon systems components, communications equipment, and vehicle parts.

This industry at which the Swiss machining has emergent as the watch and the jewellery industry further uses the technology in making accurate features. The luxury timepieces have high precision and elaborate surface finish that Swiss machining is perfectly matched.

Swiss machining is applied in oil and gas industries in its down hole tools, valves and parts of instrumentation that require working in harsh conditions. Swiss machines are specific in the precision and variety of materials that they can work with and are appropriate in these high-demanding applications.

Quality Control and Precision Standards in Swiss Machining

Quality assurance in Swiss machining starts by setting up and calibrating the machine. The guide bushing system needs to be positioned very accurately and the locations of all the tools should be well programmed, to guarantee high level of part quality. The maintenance and calibration of the machine should also be regular to meet the standard of precision.

The most common statistical control applied in Swiss machining is called statistical process control (SPC). Monitoring the important dimensions and process parameters on an ongoing basis helps the manufacturers to realise trends and take action to correct them in time before the parts cross the specification limits. The involvement of this aspect of quality control will save on waste and guarantee the quality of parts produced.

Dimensional inspection of the Swiss machined part is often performed using the coordinate measuring machine (CMM). This advanced kinds of measurement systems have the capability of confirming sophisticated geometries as well as narrow tolerances with a great degree of precision and thus there is faith in the quality of the parts and their suitability with the design specifications.

Swiss machines are being increasingly installed with in-process monitoring systems. Such systems have the ability of monitoring cutting forces, vibration and any other process parameter in real time and they warn the operators about impending problems before these problems can lead to defective parts.

A precision finish measurement is important to most Swiss machined parts. Profilometers and other surface measurement machines are also applied to determine that parts conform to designated surface roughness needs. It is highly crucial especially to components that will be in contact with any other part or will need a special aesthetic quality.

In numerous industries where the Swiss machines are applied, material traceability is a necessity. Keeping records of material certifications, processing parameters, and inspection outcome in detail guarantees that parts in the application may be tracked over its lifecycle especially in the aerospace and medical sectors.

First article Inspection (FAI) procedures are normally used when installing new Swiss machining tasks. This thorough inspection procedure will ensure that all features of the parts satisfy specification requirements prior to completing full production and there is a lesser probability of manufacturing non-conforming parts.

Tooling Technologies and Cutting Tool Selection

Choice of tool plays a fundamental role in the success of the Swiss machining processes. Swiss engineering is not standard machining and the special geometry of the machine and cutting requirements necessitate special tooling that is created for a screw machine shop with this application in mind. Typical turning tools tend to need alteration or substitution with different Swiss-specific ones.

Swiss machining tends to use carbide inserts, because they are wear resistant and enable a sharp cutting edge to be maintained. The carbide grade is selected based on the material of the workpiece and each grade is optimized to individual materials (steel, stainless steel, aluminium etc).

Coated cutters have long tool life and better Swiss machining. TiN, TiAlN and other wear-retardant coatings cut down on friction, offer wear resistance, and allow increasing cutting speeds. The type of coating is selected based on the application as well as material to be machined.

The process of threading in Swiss machines is entirely special because of the peculiarities of the kinematics of the work. Thread mills, taps and single-point threading tools need to be selected and programmed to provide satisfactory thread quality and dimensional accuracy.

To the guide bushing system, the drilling tools should be able to generate precise holes and manage the obstacle of chip evacuation that comes with the system. application usually demands special drill designs with improved chip-removal capabilities.

Workholding and tooling devices are to give remarkable stiffness and precision. Deflection or any movement in tooling system will affect the part quality and dimensions directly. Premium tool holders that have accurate clamping systems are required.

Tool performance and the part quality depend heavily on cutting fluid application on Swiss machining. The cutting fluid should be able to penetrate well into the cutting zone despite the limitation caused by the guide bushing system. In special cases, complete coolant delivery systems may be necessary, to provide sufficient lubrication and cooling.

Programming and Setup Considerations for Swiss Machines

To program Swiss machines there are unique requirements in knowledge of the special capabilities and limitations. Swiss machines, unlike their conventional CNC lathes, need very careful coordination of many spindles, tool stations, and axes in order to produce maximum efficiency and quality.

An important part of programming Swiss machines is part synchronization. The programmer needs to pay very good attention in ensuring that the movements of the main spindle, sub-spindle and other tool stations are synchronized to ensure that the work is carried out in the proper order and at the proper speed. It is necessary in terms of quality and collision prevention.

Swiss machining cannot be performed as easily because tool path optimization is more complicated because several things are happening at once. Efficient tool paths have to take into account such things as tool interference, chip evacuation, and cutting force distribution, among others, when programmed by the programmer. This may be greatly simplified with the use of advanced CAM software markets specifically targeted to Swiss machines.

Speedy setting up is also a point of consideration during Swiss machining. The time that is spent in switching between two jobs can also be cut out considerably by standardized tooling systems, preset tools and a very well organized setup process. This is especially necessary to the shops that manufacture different parts.

Swiss machine programming and setup can never go without simulation software. Such programs can identify possible clashes, check the paths of the tools and the cycle times prior to the actual machine being run. Such ability shortens the time of setting and limits the risk of crashing or other inconveniences swiss lathe.

The situation of workholding is special in Swiss machining because of the bar stock feeding system. The operator who happens to be the programmer needs to make sure that the stock of the bar is well supported and instructed during the machining process. Poor workholding may cause the part to distort, give bad surface finish, or incorrect dimension.

In order to ensure consistency in the machining processes in Switzerland the use of the process documentation is vital. Complex setup sheets, equipment checklists and operating guidelines are used so that the settings of the job are reproducible by running the job again in future.

Cost Analysis: Swiss Machining vs Traditional Methods

Cost analysis of Swiss machining as opposed to traditional machining needs to involve several factors other than just the rate per hour of the machine. Although Swiss machine initial capital costs and costs of operation per hour are usually greater, the distinct features of Swiss machine applications may make overall part costs less, particularly as they reduce setup time cnc swiss machines .

One of the key cost benefits of Swiss machining is the reduction of the cycle time. The capacity to do several operations all at once is capable of cutting half or more cycle times in comparison to the traditional processes of machining. This shorter cycle time has a direct effect of reduced costs of parts particularly where the production process is high.

Another large savings is the elimination of secondary operation. The Swiss machines have the capacity of completing parts that would have demanded several setups as well as numerous operations on the traditional machines. This ability saves on handling costs, work in progress stock and limits the chances of a mistake that may arise in the movement of the parts.

In many applications, labor costs give Swiss machining a helping hand. Automatic bar feeders and lights-out that are available in Swiss machines have the potential of cutting down on direct labor significantly. Depending on the Swiss machines, some may require a single operator to work to even more Swiss machines and increase labor efficiency.

Swiss machining may incur tooling expenses compared to the normal machining since cutting tools and holders needed are special types. But, in most cases these expenses are economized by the extended life of the tool caused by the steady cutting conditions that the guide bushing system gives.

Simply the superior precision and repeatable nature of Swiss machining tends to reduce quality costs by reducing inspection, rework and scrap. The resulting cost savings on quality-related expenditures can be drastic, especially on high value products or applications that have critical quality provisions.

In most cases, material usage is improved with the use of Swiss machining because of the bar stock feeding method and machining near the final bar end. Such a better use of material can save a lot of costs, especially in cases such as machining of high-cost materials.

Future Trends and Innovations in Swiss Machining Technology

Several major technological trends are currently defining the future of Swiss machining in general, and the key role that such systems have to play in the modern manufacturing environment in particular. With the integration of automation and Industry 4.0, there are considerable transformations in the operation of Swiss machines along with their connection with the manufacturing systems.

The introduction to Swiss machining systems of artificial intelligence and machine learning is underway. Such technologies allow optimizing cutting parameters in real-time, estimating tool wear, and adapting processes without any human interaction to continue working at optimal levels firing pins. Further automation of processes through AI is another technique that is expected to enhance the efficiency and quality of the parts and that also minimises the level of skill needed on the part of those involved in the process swiss watchmaker jakob schweizer.

Computerized sensor technology is permitting more advanced monitoring and control of the Swiss machining processes. Complex sensing systems such as vibration sensors, acoustic emission monitors, etc. can alert the operator of problems before they lead to any defects on the parts or pain to the tools. High reliability is needed in modern manufacturing and this predictive ability is critical to achieving this.

A recent trend that has merged precision of Swiss machining and 3D printing design freedom is the additive manufacturing integration swiss machinist. The composition of hybrid machines, capable of printing as well as machining complex components, is starting to emerge, posing new possibilities, in regards to producing parts that would not be achievable otherwise using either of the processes.

Increasing multi-tasking possibilities are available following more axes and multi-functionality being added to Swiss machines by the machine builders. The five axis milling, live tooling, and enhanced use of the sub-spindle are becoming increasingly able to mill more complicated parts in fewer setups using Swiss machines.

Swiss machining technology innovation is being moved by the consideration of sustainability. Fuel saving design, better cutting fluid, and better usage of materials is gaining significance as manufacturers require being less environmentally detrimental focusing on productivity and quality automotive components.

The process of applying digital twin technology on Swiss machining is starting, and it enables modeling and optimization of Swiss machining processes virtually cnc swiss. The technology allows the manufacturers to virtually test and fine tune processes before actually putting them on the actual machines and allows the manufacturers to take less time in development and hence more success on the first time.

Conclusion

The Swiss machining system is the pinnacle of precision manufacturing technology and has the most accurate, efficient and versatile method of manufacturing complex cylindrical parts precision machining. The unusual design characteristics of the Swiss-type lathes, and in particular the sliding headstock and guide bushing system, allows parts to be produced with tolerances and surface finishes that could never be created using conventional machining processes swiss turning centers. The fact that the technology can affect several operations at the same time yet its accuracy remains unmatched has made it priceless within any given industry that concerns quality and accuracy the most.