Meta Description: Guide to molded parts and molded-in inserts including the principles of the process, design, material-selection, and best-practice to ensure successful applications of inserts with molding in 2025, while maintaining structural integrity involves melting.

Molded-in inserts is a highly important manufacturing technology which offers the durability of metal ingredients combined with the adaptability of the plastic material, especially in the consumer electronic industry . The guide offers an in-depth description of the fundamentals of insert molding, which will allow the manufacturer and designer to get an informational basis to develop durable and cost-efficient goods. With the introduction of complexities into the global supply chains, knowledge of such processes is crucial in as far as businesses are concerned with coming up with efficient manufacturing solutions to reduce assembly and labor costs mold opens.

Understanding Molded-In Inserts Fundamentals

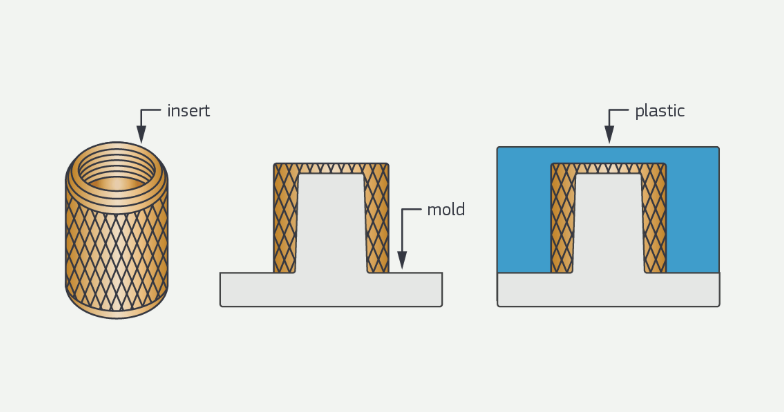

Insert molding process entails the injection molding process which incorporates inserts, especially metal in an injection-molded component, and may require heat treatment for optimal performance . The process permanently cements equally similar but different materials and this creates components that exploit the superior properties of both metals and plastics. The process has transformed the manufacturing of many industries since it allows the companies to produce lightweight but robust components.

The main idea is to insert metal components into mold cavities after which molten type of plastic material would be injected. During the cooling and solidification of the plastic, the bond between it and the insert is mechanical, ensuring a solid bond so that a single component is produced. This technique removes secondary assembly processes and it also minimizes the occurrence of component failure because of loose connections.

Modern plastic insert molding has moved beyond mere metal-plastic assemblies and into a wide variety of geometries, types of inserts, and special material types such as natural rubber with specific functional requirements.

The Insert Molding Process Explained

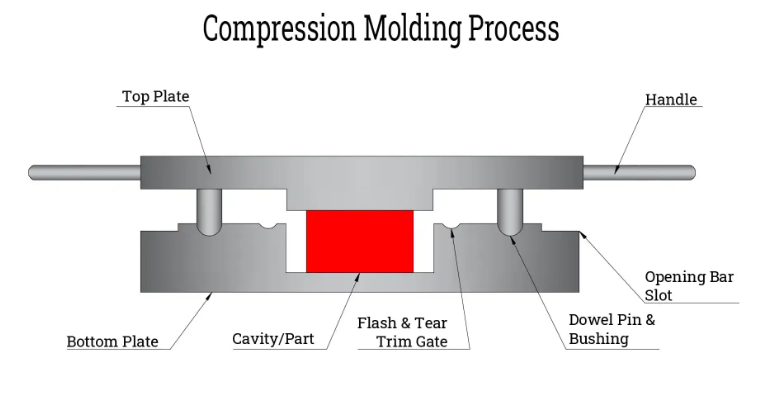

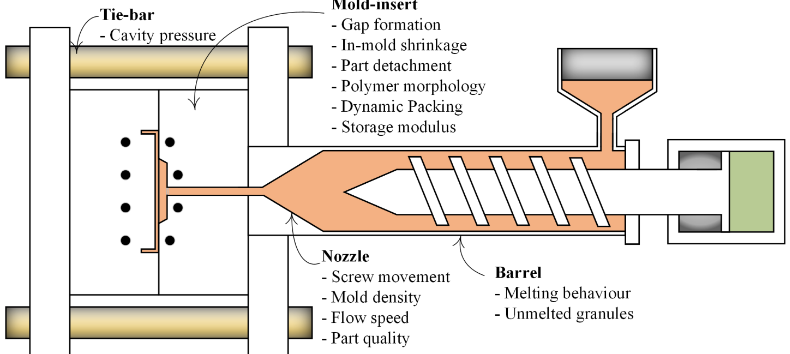

Insert molding bears striking resemblance with the conventional injection molding. It entails melting and injecting molten raw materials or plastic into a mold using the injection molding materials, which are common in the conventional plastic molding. It starts with the insertion of the care in the mold cavity then injection of the plastic with the controlled temperature and pressure heights, while managing any excess material effectively .

Its molding cycle contains a number of important steps: mold close, plastic inject, packing and holding, cooling, ejection of part. The hook has to be accurately controlled during each of the stages to get proper flow of plastic around the insert and sufficient bonding strength. Specific attention should be focused on the temperature control because overheat can destroy valuable inserts and insufficient temperature can lead to the low adhesion of the plastic, causing internal stress in the final product .

In-process quality control is achieved by observation through injection pressure, melt temperature, mold temperature, and the cycle time, especially when dealing with non plastic parts. Advanced molding systems introduce real-time feedback mechanisms to maintain the consistent values of the process parameters and guarantee the possibility to obtain repeatable results.

Critical Design Considerations for Success

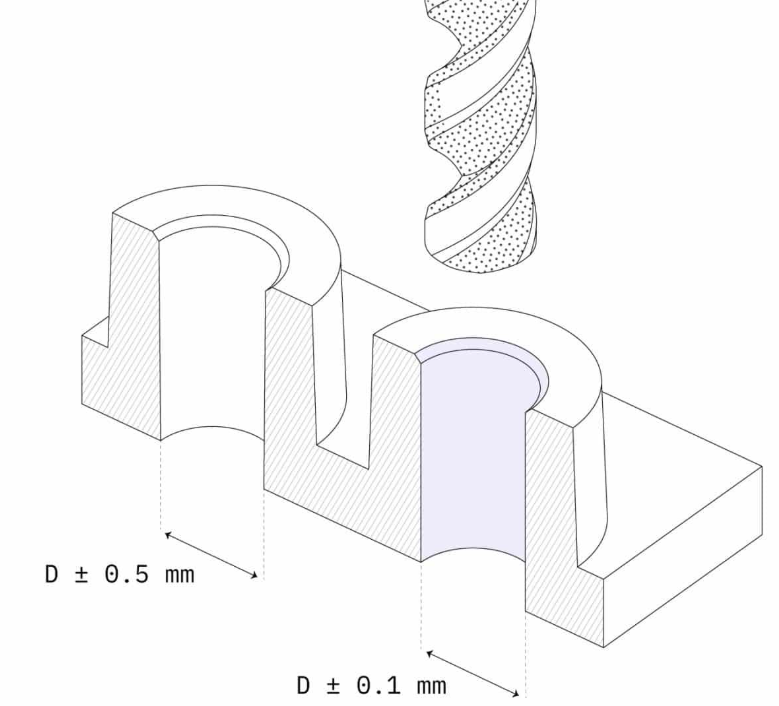

Most insert molding is successful, but should take into account a number of design considerations that work together to affect the ability to manufacture and the performance of a product, particularly in the context of medical devices . Stress concentrations and possible cracking are avoided by making the wall thickness uniform around inserts. The plastic material has to flow easily around the insert geometry and in order to achieve this draft angles must be sufficient, and radii on transition points must be quite large plastic injection molding.

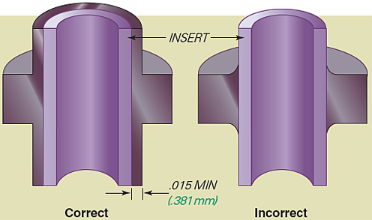

The orientation of insert in the mold influences the plastic flow patterns as well as final part strength, which is critical for the functionality of surgical instruments . Designers shall also take into account the positioning of the insert during the molding process and how there is sufficient plastic coverage so that they can be retained securely. Contact surface between insert and plastic must design so as to provide maximum contact area and so as to achieve good mechanical bonds.

The placement of gates in relation to the insert location influences plastic flow and the possibility of weld line formation. When the gate is placed properly, there is total filling around the insert with molten material and the minimum visual defects keep the structure in place. Complex insert geometries, or large parts may require multiple gates.

Material Selection Guidelines

Matching of materials between the inserts and plastic resins has a huge influence on the strength of the bond and the permanency, making it an essential cost element in the production process . It is economical and provides the best design flexibility since it involves either plastics and metal (or any material) to provide part reliability and strength. Typical materials used in metal insert molding are brass, steel, aluminum and special alloys of aluminum chosen in special applications.

The choice of the plastic resin also relies on the operating temperature, chemical resistance requirements, mechanical property requirements, and its deformation temperature. When properly processed thermoplastic materials have very good flow properties and bond well to metal inserts. Laser transmissions require more performance, which is offered by engineering plastics such as nylon, polycarbonate, and POM.

When these two materials, insert and plastic ones have differences in their thermal expansion coefficient, stress concentrations during temperature cycling can be produced. These differences should be minimized with material selection being able to provide performance characteristics that are necessary, including options for rubber like plastic . Inserts can be treated on the surface to increase adhesion and have an overall strengthening effect on the bond.

Insert Types and Applications

The most common use is threaded inserts giving reliable mounting points to a plastic part, particularly in applications like medical knobs . These inserts have special geometry, which increases the locking plastic by means of mechanical interlocked. Additional holding power is achieved with knurling, undercuts and barbs to prevent rotation of the insert when performing the service.

Electrical inserts are intended to connect and support in a relatively reliable way electronic devices offering EMI shielding as well as environmental protection. Such special parts very often bring together functions such as solder cup, terminal blocks, or connector interfaces directly in the plastic housing, all managed by the injection unit.

Structural inserts are used to strengthen high-stress point regions in plastic parts by spreading the loads across a broader area thus stopping localized failures. There exists a wide variety of applications of these materials in automotive and aerospace components where weightsaving and strength considerations govern aspects of design, particularly for cost sensitive parts .

Mold Design Principles

Insert insert molding necessitates the specific mold design as opposed to the usual injection molding. In designing molds, one should calculate the location of the areas that need inserts bearing in mind the structure of the product and not to add unnecessary insert. Insert positioning systems should both identify and fix the components precisely on the molding process, ensuring that vents present are properly managed .

Ejection system design also becomes more complicated in presence of inserts where the design must be carefully laid out to prevent damages and displacement of inserts. Insert geometry has to be considered when placing pins as well as having significant ejection capability. Depending upon the complexity of the insert, specialized ejection mechanisms may be required.

The design of cooling system should facilitate a uniform temperature in the area of inserts so that thermal stress and dimensional distortion are avoided. The cooling channels should also be distributed strategically in order to make sure there are proper cycle times and plastic is cooled enough with regard to the metal parts.

Automated vs Manual Insert Loading

Volumes of production and complexity of part determine the most suitable insert loading method. Auto insertion applies robots and other automated manufacturing processes to add parts to a mold. Automated insertion advantages are that this type of insertion can be repeated on a regular basis and it is efficient and precise. The return on automation investment is usually worth it in terms of high-volume production due to better consistency and low labor costs.

Manual loading can still be an option in low volume production or prototyping whose flexibility and low starting cost are more important. Low-volume production is best suited when it is done by hand. It is a process of placing components manually in a mold. But manual processes need technically trained operators and can carry introduction of variability to positioning of inserts.

Hybrid systems involve the use of automated mechanisms to carry out the key functions with manual processing of exceptional or sensitive parts. The strategy is cost effective and accommodating at the same time without compromising quality.

Quality Control and Testing Methods

Insert molding quality assurance In insert molding there are several testing procedures performed to prove bond strength, dimensional accuracy, and performance attributes. The pull out testing identifies the mechanical strength of insert-plastic interface at different loads. Torque tests determine threads insert performance and their ability to resist loosening.

Inspection techniques designed to locate the presence of voids or non-bonded regions surrounding inserts are via ultrasonic non-destructive testing. X-rays may be used to detect internal defects and insert positioning errors without destroying any component. These methods are especially useful with applications that are critical in nature and failure may cause grave effects.

Statistical process control is a method that checks the major parameters in the process of production in order to spot trends and avert defects. By means of regular sampling and testing, continuous quality is maintained with the inspection costs kept at minimum. The inspection systems can be integrated online into production lines whereby the real time qualified conditions of the object to be inspected are checked.

Common Design Challenges and Solutions

Insert molding presents another challenge of inserting during molding in that it involves high details of mold design and process control. This risk is reduced through proper insert retention systems and optimized injection parameter. Molded in inserts need an operator to put his hand in the mold cavity; which also constitutes a breach of reasonable safety in most locations and emphasizes the significance of automated loading systems.

The stress concentrations or dimension inaccuracy may occur at the plastic shrinkage of inserts. The shrinkage patterns are affected by gate placement, cooling design and the choice of material. Compensation methods comprise changes in the size of molds and processing optimization.

Insertions may also cause parts to be weakened and may also cause the establishment of weld lines that introduce cosmetic defects to the areas surrounding the inserts. Several gating strategies and control of the mold temperature aid to reduce the visibility of the weld lines and the strength loss. Geometry alteration of parts might have to be done to redirect plastic flow patterns.

Cost Analysis and Economic Considerations

The economics of insert molding is related to the amount of production required, complexity of part and its performance characteristics relative to other manufacturing processes. Insert molding is also one of the most economical processes followed by manufacturers since it is a single-shot-only process, minimizing post molding assembly . Tooling costs are initially more expensive than traditional molding but this is compensated with less assembly processes.

Insert and plastic costs are the material costs with insert costs being in many cases a large share of the part cost. Costs of materials can be controlled through volume buying deals and relationships with suppliers. Conventional insert designs or new materials could be less expensive, but offer equal performance.

The difference between the manual and automated loading system is considerably large as far as the costs of labor is concerned. Compared to manual systems, automating typically needs more cash outlays at first but also generates huge savings in labour and an increased degree of uniformity, frequently justifying the cost premium on high-volume use. Through keen scrutiny of the needs of production, one gets to know the best method.

Industry Applications and Case Studies

Automobiles use insert-molding in making lightweight parts that incorporate medical enclosures and fastening systems. Plastic materials become durable with metal wrapped in dashboard assemblies, door handles and electronic housings. The gains through weight reduction helps in enhancing fuel efficiency with the necessary performance conditions.

Insert molding is applied in manufacturing medical equipment components to cover surgical devices, diagnostic devices, and implantable devices that operate under specific service temperature . Stringent quality demands and biocompatible effects promote special processes and materials. The possibility of merging several operations in one part makes things easier to fit and minimize contamination threats.

Electronics applications are connector housings, EMI shielding and heat dissipation elements that also require humidity control . Insert molding also allows complex geometries as well as good electrical and thermal property. With trends in miniaturization, manufacturing is getting more accurate.

Advanced Technologies and Innovations

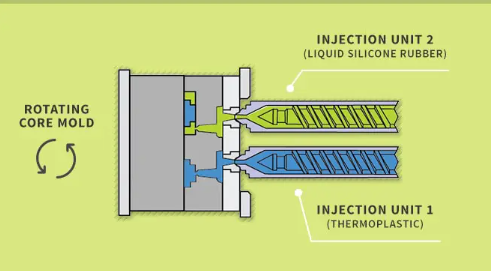

Multi-shot injection uses the combination of insert injection molding and a multiplicity of plastic injection that is used to produce intricate components made of multiple materials. The technology also allows the production of products whose material properties are different in different regions whilst retaining an integrated construction. Its applications have the use of soft-grip handles employing chair-rigid structural cores..

In-mold assembly processes combine several inserts and component together in one mold. The method minimizes assembly tasks and still maintains accuracy of component relationships. Relatively high-end mechanisms can be partially assembled in the mold which eliminates manufacturing steps down the line.

AM is being increasingly applied in prototype inserts and specialized tooling components. 3D printing allows quick iteration in the design and geometries of inserts to specialize the part in an application. Metal printing technologies deliver production inserts in the purposeful use.

Environmental and Sustainability Considerations

There is an ever-growing trend in impacting the environment and the ability to recycle materials that are selected to be used in insert molding. The bio-based plastics and recycled content materials are the alternative products that can be implemented in insert molding and overmolding without sacrificing in terms of performance needs. Product development is assessed by the total environmental impact of the product by using life cycle assessment.

Disassembly design matters when it comes to products in which the material in the end of its life is valued. Insert materials and plastic resins have to be recyclable or easy to extract into separate streams of materials. Decent marking of components and labeling of materials will help in disposal.

An efficient means of manufacturing consumption lowers cost of operation as well as environmental output. On optimized processing conditions and enhanced control system requirements help limit energy requirements and still get the quality requirements. Waste reduction measures consist of use of regrind and optimized systems of runner.

Future Trends and Developments

Industry 4.0 is reversing the traditional insert molding industry to have better process surveillance and predictive maintenance features for the plastic insert molding process, which can be viewed as a two step process . The opportunity to collect quality and equipment data in real-time for digital control panels and analyze it makes proactive management and equipment optimization possible plastic inject molding process. The machine learning algorithms determine the processing parameters that are best suited on new applications molten plastic.

Material advances keep broadening insert molding applications by the development of new plastics and by the development of special insert materials and insert injection molding process. The high-performance polymers allow operating at severe conditions and providing low costs. Intelligent materials containing built-in sensors open the possibilities of combined monitoring systems.

The innovations in automation are adaptive manufacturing systems that react to fluctuations in production needs, as well as collaborative robots. Flexible manufacturing cells are able to cope with many different types of parts and insert schemes and carry out changeover in a short time. The features facilitate bulk customization and short product development life cycle.

Global Supply Chain Considerations

Manufacturing on an international scale warranties prudent coordination of material procurement, production planning, and logistics. Insert components are normally ordered with special suppliers with particular skills and certification. It is in the supply chain resilience that has become important in the production schedules and the quality standards.

We know how to use the global manufacturing supply chain at GWT Worldwide. Being a professional logistics service provider majoring in global freight forwarding and supply chain management, we assist manufacturers with their broad-range logistics services covering air freight, sea freight, China-Europe rail transport, worldwide express business, custom clearance, and warehousing. Our manufacturing experience in making parts guarantees easy delivery of the parts form origin to destination in a scheduled delivery and quality oriented manner.

Different regions have differing standards of quality and certification and one has to carefully evaluate the suppliers and monitor them constantly. Material certificates, processing records are certification of compliance, which document international shipments. Good documentation saves delays and compliance to the regulations.

Risk Management and Mitigation Strategies

There are supplier chain vulnerabilities that may have a strong adverse effect on insert molding activities because of specialized component needs. The fact that we have diversified supply networks and strategic supply management enables the continuity of productions. High value components should be devised with alternative sourcing strategies.

Validation of processes and capability tests enables to achieve constant quality in various production equipment and plants. Training and have standardized procedures are consistent everywhere and by whoever applies them. Compliance with standard is checked through regular audits.

Product liability involves the necessity to have the decisions of the design, choices of materials, and quality controls thoroughly documented. The insurance cover must claim the possible failure modes and respective consequences molding solutions. Being able to clearly communicate the limitations of any application as well as its maintenance needs when dealing with customers eliminates liability exposure.

Conclusion

Molded-in inserts design is an advanced technology of manufacturing which allows production of molded parts, high performance cost effective products in various industries. The factors that are needed in order to succeed are attentiveness to material selection, design streamlining, process control, and quality assurance within the production cycle.

Advancement technologies and sustainable processes keep increasing the functionalities and uses of insert molding. The firms that have learned to exercise such methods have competitive advantages in terms of higher product performance, low cost, and customer satisfaction overmolding insert molding. Compliance with design rules and good practices makes results obtained stable and repeatable and capable of meeting challenging specification requirements liquid plastic.