DIY CNC vacuum table construction diyvacuumtable.com. Find products, design ideas, build techniques and workholding solutions to professional results.

Construction of a CNC vacuum table redefines your machining activities since it offers steady and safe workholding on the entire surface. In this new guide, you will take a step by step process of building a professional grade vacuum table system that can replace even commercial offerings and still save a substantial amount of money. Either as a hobbyist or a professional machinist, being aware of the structure of a vacuum table can present new opportunities to create precision work and greater productivity.

Understanding CNC Vacuum Table Fundamentals

CNC vacuum table is based on the concept of atmospheric pressure differential, which generates strong holding force on workpiece surface. It has a vacuum pump that depressurizes enclosed bases under the table, so that the materials are tightly held under the pressure. The technique makes it dispensable to store mechanical clamps in numerous cases and offers free access to the tool and even distribution of pressure.

The holding force created is dependent on a number of factors such as vacuum level, the area of surface contact and also the porosity of the material. As correctly designed the system can produce holding forces of over 14 pounds per square inch, which is more then adequate in most machining applications. Comprehension of these principles assists in the development of an efficient system that could satisfy your definite machining demands that do not compromise safety and stance.

Essential Materials and Components Selection

A good choice of materials is the core of a successful DIY project of a vacuum table. The surface on the table is normally made of MDF (Medium Density Fiberboard) or phenolic resin boards which are selected due to their stability, machinability and ease of sealing. MDF can be well valued and good performing in most of the uses whereas phenolic is more durable and has high resistance to chemicals in harsh conditions.

Vacuum systems need special pumps, which are able to guarantee constant negative pressure. The rotary vane pump works best in CNC because of the continuous operation and also when the pumps keep on providing vacuum irrespective of small leaks. Whether or where to put the pump would be determined by the surface area of the table and the desired air leakage, which most homemade systems are in need of 5-15 CFM capacity. Other parts are vacuum gauges, relief valves, filtrating systems and proper plumbing material used in vacuum application.

Design Principles and Planning Considerations

Holding force, material compatibility and manufacturing feasibility are the three factors which must be balanced in the design of an effective vacuum table. Vacuum distribution and flexibilities of the workpiece depend on the grid patterns and generally presents as rectangular grids, circular patterns, or a hybrid of both. Finer grid spacing has a higher holding force but needs additional machining time, larger grid range covers a large set of work piece sizes over a lower complexity.

The depth of the chambers has a huge influence and deep chambers give more air volume and consistent vacuum. Nevertheless, some depth is too much and will only increase the amount of material and time needed on a machining operation. Depths of 0.25 to 0.5 inches are used in most successful designs, where the depths offer the best combination of performance and convenience/reliability. When completing design specifications, consider types of materials, common workpiece sizing and machining needs.

Step-by-Step Construction Process

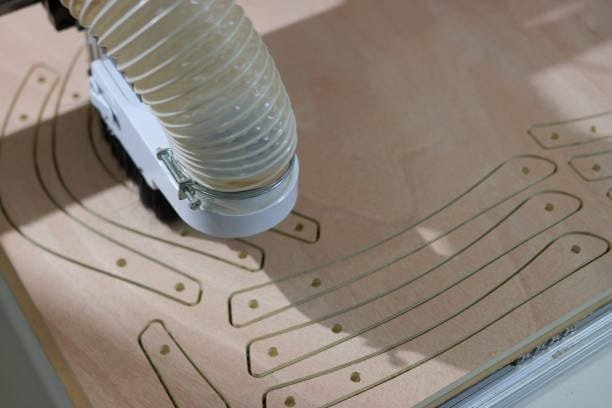

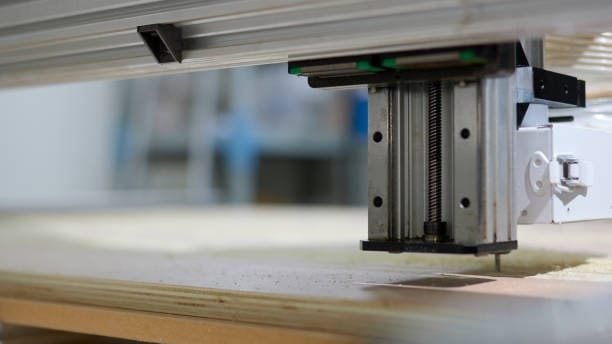

The construction process starts with the preparation of the base material so that it can have flat, stable surfaces through which the machining of the vacuum chambers can be done. Employ the application of precision measurement instruments to delineate grid patterns to ensure that there is consistency in interval and fixity across the table top pvc pipe. CNC machining would give most accurate results but meticulous manual machining with good tools will give satisfactory result in several applications, especially when channels are involved shop vac .

Chamber machining must use sharp tooling and must use proper speeds to avoid tear-out or rough surfaces small holes. Make chambers out of end mills or router bits with smooth edges and equal chambers depth to ensure proper sealing. Make vacuum fittings on strategic places, either by means of threaded-inserts or direct-tappings, depending on the thickness of the material. Individually connect chambers by drilled passages or external manifolds with no obstruction to the air flow through the entire system hardware store.

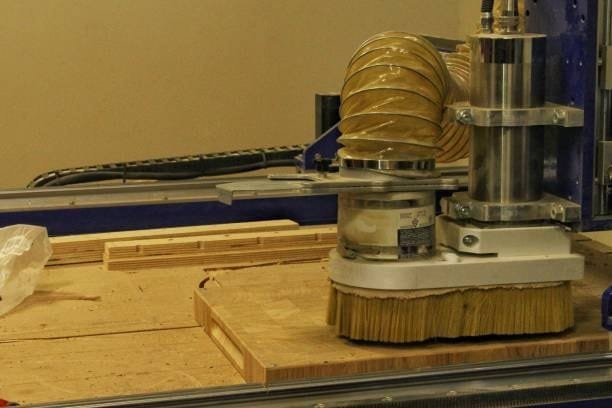

Vacuum System Setup and Configuration

Noise, vibration isolation and access during maintenance need to be taken into account in vacuum pump installation. Position pumps that do not come in direct contact with sensitive machinery, but it is launched at a distance that is reasonable to avoid high pressure losses. Install the vacuum gauges by the place of the pump outlet and the table place so that to observe the system performance and recognize the possible problems.

Filtration helps avoid debris in vacuum pumps that prolong equipment life and performance. Use table to pump filters with tables of the right micron rating to suit your applications. Vacuum relief valves prevent excessive evacuation as well as ensure fast release of a work in case of necessity. Electrical control is designed to be easily operated with the facility of emergency stops and status lights enabled.

Workholding Techniques and Best Practices

Vacuum workholding Vacuum workholding presents special challenges in material characteristics and surface preparation conditions. Flattened surfaces- or smooth surfaces make the best sealing but textured or porous materials might need some more ways of sealing. Sacrificial spoilboards will cover the vacuum table surface and allow work on the different thicknesses of the workpieces with adequate sealing.

A position of a workpiece influences distributing the holding force and machining outcomes. Place heavy pieces over several vacuum areas so that the entire processing process is well-supported. With oddly shaped work, deformable modeling clay or special gaskets should be used to obtain good seals around perimeters of workpieces. Before starting any machining practice, make sure that holding force is adequate, and testing can be done by increasing the feed rate gradually until a good set of parameters is achieved.

Troubleshooting Common Issues and Solutions

The causes of vacuum level issues are related traditionally to leaks of the air, problems of the pumps, or blockings of the system cnc router. Baseline vacuum tests at different points in the system are taken to determine points of pressure loss. Listen through the leakage detection packages or sounds in case of infiltration of air finding where they should be corrected.

Contamination, wearing out or improper maintenance are common causes of pump degraded performance. Frequent oil changes, filtering replacements and frequency of inspection averts majority of the issues to do with the pump. Test vacuum gauge in the operating conditions and monitor a possible change indicating the emergence of certain problems that need to be addressed before the entire system fails.

Maintenance Requirements and System Optimization

Maintenance promises vacuum table stability and increases the life of system components. Among the daily activities, one should include checking the level of a vacuum, the visual exam of the possible damage or contamination, and the process of surface cleaning. Maintenance should be done weekly and includes inspection and cleaning of filters and every month plans should be made of entirely looking at the system and servicing the pumps when necessary.

Performance optimizing is the fine tuning of the vacuum level, grid setup, and operating processes to occur according to real usage. Record the effective workholding arrangements of various materials and operations and make a reference database system so that further projects can be worked on. Look at upgrading the systems used, i.e. zone control valves or automated switching systems to meet and exceed your machining needs.

Cost Analysis and Return on Investment

The home-built vacuum table is usually 40-60 percent cheaper than commercial one and performs similarly. Prices of materials depend on the size of the table and the quality of components, but simple systems can be built costing about $300-500 in hobby projects. Highest quality systems can cost thousands of dollars, even 1000-2000, yet they can provide years of trouble free service and much improved machining times.

Initial investments are easily recouped through simple increases in productivity and scrap rating within time savings and quality of parts. Vacuum workholding also removes setup time of multiple clamps and also offers better quality of surface finish due to less vibration and rigid maintenance of workpiece. Determine the feasibility of the project along with the returns that it would yield by calculating the payback periods using your unique production needs and the amount of labor that you may be using.

About GWT Worldwide

GWT Worldwide Shenzhen Guanwutong international Freight Forwarding Co.,Ltd. (GWT Worldwide) is a professional international freight forwarding, cross-border supply chain solutions, and cross-border e-commerce logistics service provider. We provide a whole range of services: air freight, sea freight, transport in China-Europe railway, international express delivery, Customs clearance, warehousing, and assistance in shipping on Amazon FBA. We have logistics technology and a global network of trusted partners to provide businesses around the world with efficient, transparent and business-focused logistics solutions.

Conclusion

A homemade CNC vacuum table is an outstanding deal when a machinist desires professional workholding solutions of a commercial system without the expense. Appropriate planning, good materials and good craftsmanship turn into systems that compete with factory-built systems, and since they are customizable, features that are impossible with standard products can be built in. To be successful, one will have to consider design details, methodical approach towards the construction and adherence to the practice of routine maintenance.