Introduction

CNC screw machining is one important industrial process combining speed, accuracy, and automation. From manufacture of small, specialized items to high-volume components with unmatched consistency, CNC screw machining is vital in sectors including aerospace, the automotive industry, electronics, and medical devices. This book looks into CNC screw machining in great detail, its methods, advantages, applications, and future directions.

What is CNC Screw Machining?

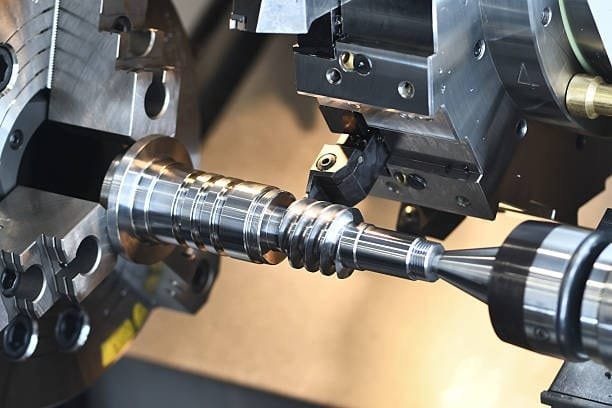

Screw machining—also known as computer numerical control—is a subtractive manufacturing technique producing accurate and detailed screw-shaped components using automated technologies. Custom designs and mass manufacture would find this technology ideal as it can control complex geometries with amazing accuracy and tolerances. High accuracy assured by automation helps to reduce human mistake in fields involving complicated components cutting tools.

The Evolution of CNC Screw Machining

CNC screw machine and machining has developed pretty quickly over years. Conventional screw machines called for regular inspections and hand adjustments. On the other hand, modern CNC screw machines include electronic controls that may automatically complete the machining operation process. By way of better productivity and cost control, this development has transformed precise manufacturing.

How CNC Screw Machining Works

The CNC screw machining process unfolds through multiple essential stages.

- The planned component receives its initial design framework through a CAD (Computer-Aided Design) model created by engineers. This computerized plan specifies the dimensions alongside the required tolerances and material specifications.

- The CNC machine follows cutting speeds and tool changes through movements determined by G-code translation of the CAD design. Current software systems streamline the CNC process which leads to better precision and decreased setup durations.

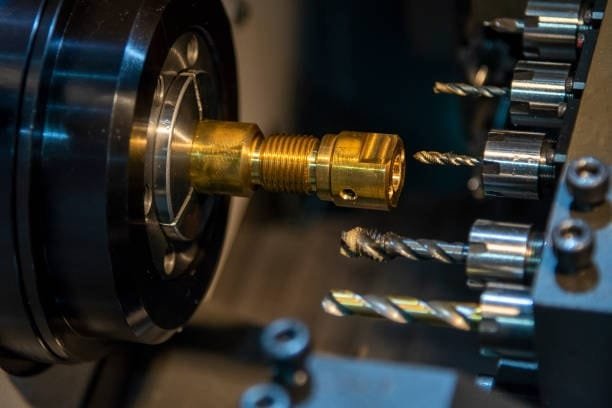

- This work makes common use aluminum, brass, stainless steel, titanium. The application guarantees best performance and durability by deciding the used material.

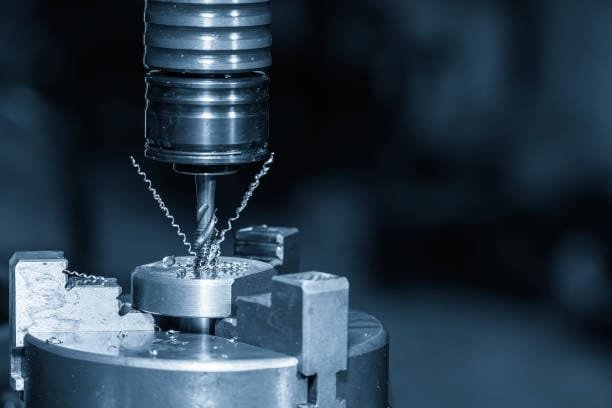

- The CNC screw machine runs automatically precise drilling, cutting, and threading processes. Several axes of movement in cutting tools let complex designs and difficult geometries possible.

- Parts are deburred, polished, or coated to match industry requirements. Furthermore done are post-machining treatments including heat treatment, anodizing, and plating to enhance look and durability.

Types of CNC Screw Machines

Aerospace business of CNC screw machining consists in several types of machines meant for various industries with specific manufacturing requirements tight tolerances:

1. Swiss CNC Machines

- These machines are ideal for creating tiny complex parts with high precision.

- machining gains enhanced stability from the use of a movable headstock.

- The Swiss CNC Machines are typically used in the production of medical equipment components, watch mechanisms, and electronic devices producing components.

2. Multi-Spindle CNC Machines

- These machines come equipped with multiple spindles to handle various machining tasks simultaneously.

- Big volume manufacturing significantly decreases production times.

- This machine type serves industrial tool creation and manufacturing of fasteners along with vehicle components.

3. Single-Spindle CNC Machines

- Single-Spindle CNC Machines work best when producing small quantities of specialized parts.

- offers remarkable precision and freedom high volume production.

- Precise instruments and specialized screws commonly serve aircraft parts manufacturing needs.

Key Advantages of CNC Screw Machining

CNC technology becomes the preferred machine of choice in precision manufacturing because of the multiple benefits it offers compared to screw machining.

- CNC screw machines deliver guaranteed precision tolerances which ensure accurate components regardless of design complexity tight tolerance components.

- Automation eliminates human error while minimizing manual labor which streamlines production processes.

- Efficiency: The system delivers minimal downtime while producing large parts volumes within short production periods.

- Versatility: This technology handles intricate designs while it works with materials including plastics and metals.

- Industries that need identical products benefit from consistent manufacturing which delivers uniform products during large production runs cam machines.

- Through automation of repetitive tasks and material waste reduction manufacturing efficiency improves which results in expense savings.

Common Applications of CNC Screw Machining

Reliable machine increasingly employed in many different fields as CNC screw machining generates high precision and durable components:

- Aerospace: Engine precision parts, hydraulic systems, landing gear all depend on perfect accuracy.

- Medical equipment including precisely tolerated components for surgical tools, implants, and diagnosis instruments.

- Automotive: Fuel injection systems, engine components, constant and robust brake assemblies

- Electronics: Circuit board mounting calling for connectors, sensor housings, and precise finishing.

- Defense: Military gear needing high-performance components, firearms parts, and communications gadgets swiss type machining equipment.

- The use of CNC screw machining is an absolute requirement for the production of fasteners, adapters, and precise fittings swiss machining.

- CNC machined components have a variety of applications, including those in power plants, oil rigs, and energy-efficient systems.

Choosing the Right CNC Screw Machining Service

Consider the following as you decide on a CNC screw machining supplier:

- Expertise: Verify the supplier’s past performance of parts for your industry before hand. Search for companies in your area of knowledge for improved accuracy and performance.

- Technology: Look for modern, extremely fast and accurate CNC equipment.

- Material Options: See if the required supplies allow your product to meet its needs.

- Select services following ISO certification requirements with consistent output and quality control

- Analyze their ability to meet specific design requirements for customized components.

- In fast-paced companies, timely delivery is rather important; consequently, ensure sure the provider meets production requirements precision components.

Advice for Maximum CNC Screw Machining Performance

As you choose a CNC screw machining supplier, give the following some thought:

- Expertise: Check historical part performance of suppliers for your sector before hand. Look for businesses in your field of expertise to raise accuracy and performance standards.

- Technology: Search for contemporary, quite capable CNC machines to guarantee accuracy and speed.

- Material Options: See if the necessary components let your product satisfy its needs.

- Choose services depending on constant output and quality control under ISO certification criteria.

- Analyze their ability to meet specific design requirements for customized components.

- Turnaround Time: Timely delivery is rather important in fast-paced companies; so, check sure the vendor meets manufacturing targets cnc swiss screw machine.

Future Trends in CNC Screw Machining

As technology advances, CNC screw machining process maintains front-edge:

- By means of smart systems for rapid adjustments, integration of artificial intelligence and automation increases production accuracy and efficiency.

- With improved tooling technologies, it is possible to achieve faster cutting rates, increased durability, and precise machining with specialized tools swiss screw machines.

- Data analysis is included into smart manufacturing to enable accurate tracking of performance and implementation of predictive maintenance.

- Among sustainable practices, lowers material waste, maximizes energy use, and makes advantage of environmentally friendly machining fluids swiss screw machine.

- For remote monitoring and process enhancement, CNC machines are gradually using Internet of Things (IoT) technologies.

Conclusion

Absolute necessity is CNC screw machining, which drives production of high precision parts re-engineered components. Its versatility, great precision part, and economy will help industries needing high-performance components discover the ideal solution. Knowing the processes, machine types, and best practices enables businesses to maximize their production output while nevertheless meeting rigorous industry standards swiss screw machining. As long as sustainability, tooling, and automation are developing, CNC screw machining will always be a pillar of accuracy manufacturing.