Learn the big extent of difference between Sinker EDM and Wire EDM machining processes, including the role of dielectric liquid . Find out about applications, benefits, limitations and selection of appropriate EDM technology in manufacturing.

Introduction to Electrical Discharge Machining (EDM)

The use of Electrical discharge machining (EDM) illustrates a technological advancement in high-quality production that is a radical game changer in manufacturing complicated parts and complex patterns. This is an advanced machining used in material removal by making precise electrically charged discharges on conductive work pieces and it has the capacity that cannot be accessed by conventional methods of machining. On the contrary to the methods of conventional machining, which utilize the actual contact between cutting tools and workpieces, EDM uses multiple short electrical sparks, which wear off material to an extraordinary extent.

The actual philosophy of EDM is one that entails providing a pattern of controlled electrical flashes between a workpiece and an electrode whereby both are immersed in a dielectric fluid. This produces high-temperature sparks, which vaporize and molten small quantities of material, afterwards swept away by the dielectric fluid. Not requiring contact, the process allows manufacturers to produce very hard materials and whose geometry is otherwise inaccessible or uneconomical using conventional machining processes.

EDM technology has become an essential technology that is used in current production, but its nature has changed greatly since it was introduced in the 50s. It is a very good process when producing with tight tolerances, complicated internal structures, and superior finishes. Its capability to machine materials in spite of their hardness makes it quite useful in aerospace, automobiles, medical device manufacturing and tool and die manufacturing.

Understanding Sinker EDM Technology

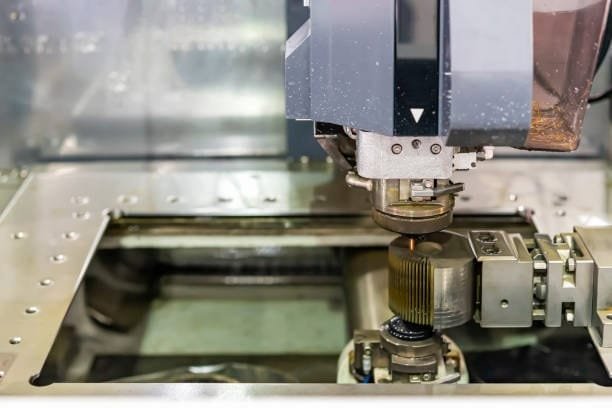

A further form of electrical discharge machining is Sinker EDM or Ram EDM or conventional EDM which is one of the most adaptable forms of electrical discharge machining. Sinker EDM involves a process of machining in order to get an electrode into a unique shape. Then it immerses the electrode deep in the forbidden material. An impression of the shape of the electrode will occur making a mold. This is why it is especially useful when it is necessary to make complicated three dimensional cavities and blind holes and complicated internal structures.

The sinker EDM mechanics starts by the formation of an accurately formed electrode usually graphite or copper. This is the tool electrode that will be a negative representation of the required hole or shape that has to be milled. This electrode is then brought above the workpiece and slowly lowered into the piece with electrical discharges between the electrode and the work piece surface taking place. The material is removed during the slowed down sparking process on the work piece as well as the electrode but the electrode wear is reduced by a low process control setting.

Along with the allowance of complex internal shapes impossible to produce by means of traditional machining, the capacity to manufacture possesses one of the most important benefits of sinker EDM. The procedure is able to create really deep holes, undercuttings, sharp internal edges, and detailed features doing it with great precision. Non-contact in nature also removes the mechanical stress which might distort the delicate work pieces therefore it is well suited to machining thin-walled parts and heat-treated metals.

Wire EDM Fundamentals and Process

Wire-cut EDM or WEDM Wire EDM uses an electrically rather different method to electrical discharge machining. In contrast to sinker EDM, in spite of the absence, in both cases, of physical contact with the work piece, wire EDM processes use a thin solid wire medium as a tool. Wire EDM can cut very hard objects and it is nearly always used to cut full-depth of the workpiece. The process is also quite good at executing high precision two-dimensional profiles and complicated contours.

The wire EDM process makes use of a thin metal wire that is constantly moving in the form of wire usually brass, copper or molybdenum which acts as the cutting electrode. Complex cuts are done using a thin metal wire that is steered by the CNC controls in the X and Y directions. Upper and lower guides guide the wire and during the job it will be moved continuously across the piece with electrical discharges taking place between the wire and material. Constant feeding of fresh wire through the cutting area makes sure that its constant cutting performance is always maintained and ensures that there are no fears of wearing out of the electrodes.

The accuracy of wire EDM is amazing with tolerance of as tight as -0.0001 inches and finishes which in many cases eliminate the need of secondary processes. It is able to cut such materials that are several inches thick and having an extremely high level of straightness and parallelism. The continuous wire feed system allows the cutting tool to be consistent during the length of the machining, which is a factor that adds to the high accuracy and repeatability wire EDM is recognized by.

Key Process Differences Between Sinker and Wire EDM

The basic differences between sinker and wire EDM go well beyond their essential operating principles and include all aspects of their performance and operation. The primary distinction of sinker and wire EDM touches on its movement and tool, contrasting sharply with traditional machining processes . Although sinker EDM can be used with a shaped electrode that is plunged into the workpiece to make three dimensional cavities, wire EDM applies a moving wire to the materials to draw them, making precise two dimensional outlines.

The two processes are studies in contrast with the electrode systems. Sinker EDM uses user-created electrodes reflecting a negative shape of the required cavity or feature. Such electrodes should be as carefully made as possible and are often costly to make particularly where highly complex shapes are involved. By contrast, wire EDM consumes ordinary wire, effectively any type of wire, making no special tooling necessary and allowing lower setup expense in numerous types of applications.

Their approaches go hand in hand with cutting abilities of each process. Sinker EDM is best for the work involving blind holes, intricate holes and 3D shapes that are inaccessible through the side. It is able to generate complex internal geometries namely features with differing depths and convoluted contours. Wire EDM will however only be able to cut through the workpiece completely and can cut incredibly finely detailed two-dimensional profiles with very intricate curves and locations that other machining techniques would be exceptionally difficult to achieve.

Material Compatibility and Capabilities

There is one important similarity to both sinker and wireless EDM processes namely that the material to be machined should be electrically conductive. The method only works well with electrically conducting metals. There is a limitation though in that range of materials that can be machined by both processes is amazing and would be hard to machine the same by traditional means.

The shortlist of strengths associated with wire EDM includes the fact that it can be used to cut a significant variety of conductive materials, viz. hardened steels, titanium, tungsten carbide, and hard-to-cut alloys. This is because the materials that are subjected to heat in order to achieve extreme levels of hardness are perfectly executed in the process because the material hardness does not affect the EDM cutting rate to a huge extent. This is especially useful in aerospace industry and medical industry where exotic alloys and super-hard materials abound.

The hardness of materials does not influence EDM wire cutting rate significantly and does not impose any restrictions regarding part geometries. Where conventional machining is slow and costly, all tungsten carbide, tool steel, Inconel and any metal harder than RC38 will be good candidates. This aspect renders EDM processes especially useful when machining parts which need to be sized-up or sized-down post-heat-treatment since it is possible to avoid distortion during the processing which might have resulted due to machining solid material.

Surface Finish and Precision Comparison

One of the few greatest differences between sinker and wire EDM relates to the surface finish traits of these processes. The surface finishes made by sinker EDM are rougher than those done by wire EDM. This is an aspect dictated by the very nature of each process and electrical parameters that are normally used.

Wire EDM always gives a better surface finish to the point that mirror-like finish can be obtained and there is no secondary finishing required. Surface roughness: having a continuous wire feed and optimal cutting parameters, the surface roughness of the wire EDM process can reach heights with a surface roughness of 0.1 micrometers Ra. This outstanding surface finish is especially useful where the surface finish directly determines the component performance as in medical implants, optical products, and precision molds.

Notably, EDM does not result in a directional surface that has a lay as in the case with conventional machining. And by very low power EDM machining in a slow manner, most of the time the craters or pock marks can be reduced to a very small size. This random texture resulting by EDM mechanism may be favorable in some applications where performance may be hindered adversely by surface directionality like in hydraulic system or bearing surfaces.

Speed and Efficiency Analysis

Depending on the application and machining material, the speed and form of efficiency of sinker and wire EDM are widely different. Wire EDM is a faster process of manufacturing. Consequently, it is more suitable when the volumes of production are high. The wire EDM continuous cutting action coupled with its stack cutting capability whereby several parts can be cut at the time makes it most efficient to then conduct production runs.

Sinker EDM has high throughput rates, again compared to the wire EDM whose throughput rate has to depend on tool replenishment, which takes time. There is however a bit of a misunderstanding to this statement as in the case of wire EDM no tool changes are normally required in the more common sense of the word, rather feeding of the feed wire. The productivity of sinker EDM is especially noticeable when it comes to the production of a number of identical cavities, the same electrode applied on subsequent occasions can be worn out negligibly.

There is also the time it takes to have any given process up and running, which affects efficiency. Wire EDM is usually less set up-intensive, needing no custom electrodes and thus more suited to prototype work and small production quantities. Sinker EDM setup consists of creation and placement of electrode, although time-consuming is frequently worthwhile in applications involving complex three-dimensional shapes that would otherwise not be made with other technologies.

Applications in Modern Manufacturing

Sinker EDM is suited to manufacture highly complex and intricate shapes by and into any conductive materials and Wire EDM is suited to high precision, excellent finish and complex geometry forms of cut types. Such related advantages ensure that these two processes can be very helpful in the contemporary manufacturing contexts, sometimes even in the same working setting.

Sinker EDM is very widely used in tool and die manufacturing where a simple mold cavity would be created to be used in plastic injection molding, die casting or forging manufacturing. It cannot do without the process of manufacturing cooling channels within the molds, complicated core and cavity features, and surface texture in the molds. Sinker EDM is used in the aerospace industry to manufacture turbine blade cooling passages, complex internal channel in engine parts, and intricate details in the landing gear parts.

Wire EDM is unchallenged in cases needing to cut thick materials, two fairly difficult shapes, and high-precision productions. Automakers use wire EDM to cut stamping dies, generate accurate gears and elaborate brackets and structures. Surgery instruments, implant parts and complex details on diagnostic equipment are made by use of wire EDM in the medical device industry.

Tooling and Setup Requirements

Tooling demands needed in sinker and wire EDM are one of the largest operational divergences in these processes. We also have sinker EDM which uses special electrodes that have to be well made to fit the required shape of the cavity. Graphite or copper is usually used in making these electrodes although graphite is preferred over copper on most applications owing to their better machinability and cheaper electrode wear rates.

The production of electrodes to be used in sinker EDM is a complex matter in which attention to dimensional control and surface finish is very important. To ensure a good fit and to allow elimination of some area discontinuity, the electrode must be machined to close tolerances, complex geometries might demand many electrodes or specially-designed electrode holders. Depending on the geometry of the product to be supplied, investment in manufacturing the electrodes may be extensive, however the novel materials processing that sinker EDM offers often makes this outlay worthwhile.

Tooling for the Wire EDM would be much easier, all that would be necessary would be the correct type and diameter of wire to suit the application. The choice of wire is influenced by the material in cut, the finishing demanded, and cutting speed among other factors. Common wire types would be brass, copper, and molybdenum where the most common type would be used in general applications, the brass type. The ease in which the wire EDM tooling can be used is more favorable with the shops that do not have a broad capability in electrodes making.

Cost Considerations and Economic Factors

Economic factors of sinker EDM Vs. wire EDM include cost of initial equipment investment, cost to operate, and particular application. Both methods require relatively high initial costs of equipment, as wire EDM equipment tends to be more expensive because of more elaborate wire handling systems and high performance CNC controllers.

The process of sinker EDM does not require consumption of power like the CNC machining. The procedure requires so much electricity to produce the appropriate energy. Both processes have operating costs that include electricity, dielectric fluid and consumables that are electrodes for sinker EDM or wire in case of wire EDM. EDM processes are energy intensive and in many cases power costs are a large percentage of costs associated with running such processes.

Economics of each process is greatly dependent on the application taken. In the course of manufacturing large volumes of basic profiles, wire EDM can be economically more efficient because it is fast and has low tooling expenses. With multidimensional features that cannot be cut using other core processes, the sinker EDM can be the only solution and cost cannot be the primary concern.

Advantages of Sinker EDM

Sinker EDM has some distinct benefits that have no alternative use in particular manufacturing processes. Possibility of making blind holes and complicated internal cavities is one of the biggest upsides of this process. It is able to trim intricate shapes, highly deep voids and undercuts that can not be carved using any other machining procedures. The ability allows the manufacture of components that have complex internal structures otherwise impossible to practice using conventional machining techniques.

Sinker EDM three-dimensional machining capabilities can realize complex contours and surface that has depth and geometrical variations. This is very useful when it comes to mold and die applications where intricate surface finishes and deep to shallow cavity requirements are often the norm. It is also able to machine multiple levels and stepped features in one set up that eliminates multiple setups and enhances accuracy due to less handling of parts.

It is the method recommended in those shapes that are deep cavities and complex in nature like in the molds, dies and so on. Sinker EDM is appropriate in those cases when the distortion of the parts should be reduced to a minimum, as sinker EDM does not put the mechanical stresses on the material that it is processing. This is of special considerations in precision mold making where, even minute distortion can influence quality of molded parts.

Advantages of Wire EDM

Wire EDM has certain advantages that have made it to be the favorite machine in many of the precision manufacturing processes. When it comes to large volumes, the better surface finish quality which wire EDM is famously known to have, in turn, can negate any need of having second finishing activities and thus end up lowering production costs and lead times. The process always has the ability to produce the surface roughness values to the most demanding specifications in a single process machining operation sinker edm applications.

The accuracy and the application of the wire EDM is accurate and is precise, as it can keep close tolerances on long cut-paths wire edm work. It is therefore suited in manufacture of precision components where the dimension of the parts is vital. The tolerances that can be obtained with this process are of ±0.0001 inches and this is with a very good repeatability of parts to part.

It is commonly applied in the making of tools and dies, and it is popular in parts which require tight tolerance and smooth finishes. Wire EDM enables cutting sharp internal corners, and intricate features within complex two dimensional profiles, a capability that cannot be matched in other manufacturing processes die sink edm. It can also stack cut to reduce several parts at once to increase productivity on some applications desired shape.

Limitations and Drawbacks

Both sinker and wire EDM machining processes have numerous limitations in spite of the numerous benefits associated with them and these drawbacks ought to be taken into account when choosing the right method of machining hard metals. The limitations of the EDM processes are associated with a number of factors which include high power consumption, excessive wear on the tools as well as long machining times suitable dielectric fluid.

Both processes include the limitation of having the requirement of electrically conductive materials. Most advanced non-conductive materials, non-conductive composites, and many advanced ceramics cannot be machined by EDM needing alternative manufacturing techniques. This constraint may regard highly when concerns advanced industries that deal with superior performance-efficient materials that are electrically non-conductive conventional cutting tools.

EDM processes have relatively low rates of material removal compared with conventional machining techniques; this may be a major drawback in cases of large-scale productions traditional machining methods. Although EDM is highly accurate and that it can machine any type of material, the time-factor of machining high volumes of materials may make it economically uncompetitive in certain applications. Also, the surface properties of EDM, desirable in certain processes, may need secondary processing in others graphite electrodes.

Choosing Between Sinker and Wire EDM

The process of choosing the right EDM is a decision that has to be thoroughly made with various factors put into consideration such as the geometry of the part, the required material, a precision requirement and of course that of a financial nature. This normally boils down to which are the actual features required to be machined and the production requirements in general wire breaks.

In products that need three-dimensional cavity, holes, or complexer internal structures, there are no alternatives to sinker EDM. Sinker EDM ability to produce features not otherwise accessed on the side creates the need to have an EDM machine as an essential part of the mold and die process, complex aerospace parts, and the manufacturing process of medical equipment that needs internal channels and holes sinker edm services.

Particularly desirable where two-dimensional profiles are required, where good surface finish is demanded, and where thick material must be cut to high accuracies, does electronic wire cutting need particular consideration. Applications that the process does well in include tool and die work where high precision cutting is desired, automotive uses where intricate profiles may need to be cut accurately and any application where the work piece can be cut through its entire thickness wire erosion.

Future Trends and Technological Advances

The future of EDM technology is still rising in the steps with innovations in the field of control systems, electrodes, and optimization of processes. Advanced EDM machineries have intricate adaptive control systems which automatically regulate the machine machining parameters by using real time feedback resulting in greater precision and efficiency electrical discharge machining process.

New and improved electrode coatings and material is prolonging the life of the electrode and the ability to produce an excellent surface finish in sinker EDM. Emerging compositions of new wires as well as coating wires EDM are making operations faster with better finishes on surfaces. Such technological improvements are rendering EDM processes a competitive task in terms of many applications as compared to conventional machining techniques.

Automated optimization of the EDM processes using artificial intelligence and machine learning technologies is starting to be achieved so that the optimization process is set to go through automatically, saving setup time, along with greater consistency sheet metal fabrication. The technologies review real-time cutting conditions and adjust them to ensure an optimum condition of the cutting operation during machining metal fabrication process.

Industry Applications and Case Studies

Aerospace industry is one of the highest consumers of the EDM technology using both the sinker and wire EDM in manufacturing critical components. The components of turbine engines must have complex internal cooling passages, which are only possible to design them through sinker EDM sinker edm machines. These parts usually require the surface finish and precision that may only be achieved by the special capabilities provided by EDM.

EDM is critical in the medical device industry in the production of surgical instruments, implants and parts of diagnostic equipment. Medical applications often require the biocompatibility and precision of materials to conform to standards and specifications that make EDM the manufacturing technique of choice other machining processes. This capacity to machine highly contoured features in both hardened stainless steels, titanium alloys is of great value in this business.

EDM in the automotive industry is quite common in the making of the tools and dies and then there is the production of parts that are very precise. All kinds of stamping dies from body panel to engine parts with complicated inner structure to transmission parts that require tight tolerance, are all subject to this EDM technology electrically conductive metals.

Quality Control and Inspection

EDM operations have their own methodology in quality control because EDM process differs with other methods. The methods of measuring surface finish have to take into account the random texture of electrical discharges, in an appropriate method of measurement and parameters cavity edm. The coordinate measuring machine (CMM) is commonly needed in dimensional inspection, which has the capacity to reach inner complicated features sinker edm process.

The heat affected zone that is formed by means of electric discharge machining needs particular consideration in the process of quality control. The heat-affected zone is generally tiny but may influence material properties and have to be taken into account in a critical application volume edm. There could be a necessity to conduct non-destructive tests to guarantee that the EDM process has not impacted the integrity of components negatively.

Recent EDM machines also allow process monitoring and control which gives real-time feedback of the cutting conditions that can be adjusted immediately to meet the standards of quality wire electrical discharge machining. These systems can report changes in the cutting conditions that may occur and alter the results of part quality, and correct itself automatically to assure the same results wire edm and sinker.

Conclusion

The decision of which of these methods to use, sinker EDM, or wire EDM will inevitably come down to the little details of the manufacturing application. The advantage of sinker EDM can be found in forming deep and large three-dimensional forms, blind holes, and internal geometrical features which are not produced based on another machining process. It is essential to mold and die and aerospace parts, as well as medical devices, because it can easily machine hardened materials without creating any mechanical stresses.

Wire EDM occupies all processes that need two-dimensional cutting with greater surface finish as well as high precision machining of thick substrates. Its reliability, good surface finish potential and the capability to hold close tolerances make it the tool/die job of choice, high precision parts and high surface finish requirements.