Introduction to Medical CNC Machining

CNC machining of medical equipment can be regarded as one of the most crucial production processes in the medical sector that should be brought together with accuracy built into the process and compliance with regulations. Life-saving medical gadgets, operating instruments, implants, and diagnostic machines that should satisfy the utmost principles of precision, biocompatibility, and security are among the life-saving products made possible by this advanced manufacturing technology.

The medical manufacturing industry places ruthless needs upon components that not merely meet strict product specifications but are also comparable to several rules in the healthcare industry such as FDA stipulations surgical procedures, ISO 13485, and added universal medical device rules precise components. Originally, this precision, repeatability and ability to work with a wide range of materials demanded by these requirements comes by way of CNC (Computer Numerical Control) machining medical machining.

The Evolution of Medical Manufacturing Technology

The healthcare sector has seen tremendous change in the technology that is used to manufacture products in the last few decades. Customary manufacturing procedures have been replaced with advanced CNC machining technology that can implement intricate geometries with tolerances in the micro meter range cnc machined medical parts medical advancements. Due to the growing need of minimally invasive procedures, customized medical devices, and better patient outcomes, this evolution has been triggered diagnostic equipment.

The CNC machining of the medical sector involves elements of modern technologies that are embodied in multiaxis platforms, online calculations, and an automatic quality control system, the presence of which allows the stable production of high-quality medical parts diagnostic equipment biocompatible materials. Introduction of both computer-aided design (CAD) systems and computer-aided manufacturing (CAM) systems has transformed the process of conceptualizing, designing and manufacturing medical products hospital equipment advanced technologies.

Core Applications of Medical CNC Machining

Medical Device Manufacturing

Medical equipments cover a wide scope of machines utilized in the treatment, diagnosis, monitoring as well as rehabilitation processes. CNC machining is essential in the production of parts in equipment like the ventilators, MRI, X-Ray equipment, defibrillators, and patients monitoring devices hip and knee replacements. Such machines need precision machined parts that can survive the sterilization procedures without losing the dimension accuracy and the functional integrity.

Medical device housings, brackets, connectors, and interior mechanisms require precise advanced geometry that can only be created using CNC machining process. The use of multi-axis machining centers makes it possible to manufacture complex parts in multiple set ups and it helps to circumvent critical issues of manufacturing time and accurate manufacturing of a part.

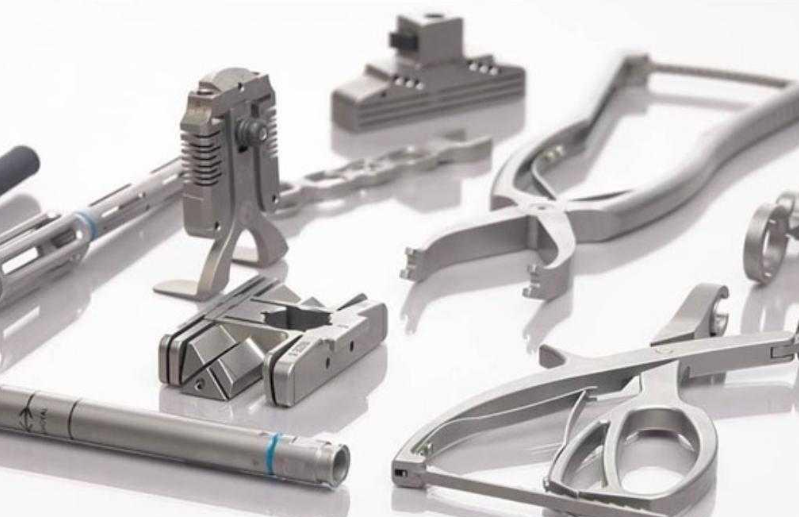

Surgical Instrument Production

One of the highest requirements of medical CNC machining is surgical tools. These tools should be extremely sharp, durable, should not break and have exact sizes. Scalpels, forceps, surgical scissors, clamps and retractors call for specialized machining operations in order to attain the necessary edge geometry and surface finish orthopedic implants.

The manufacturing of surgical instruments is not an exception since they are mostly produced in machining series which involve rough machining, semi-finishing and final precision finishing. Every phase needs enough consideration of the choice of cutting tools, cutting parameters machining and quality surveillance to make a final product with surgical standards.

Medical Implant Manufacturing

Medical implants such as joint replacements, spinal hardware, cardiovascular stents and orthopedic plates constitute the most demanding component of the medical CNC machining cnc machining ensures. These parts should have ideal biocompatibility, absolute fit, and durable tenure inside a human body.

Special material like titanium alloy, cobalt chromium alloy, and medical grade stainless steel is needed in the manufacturing of implants. The machining of such materials requires high-level cutting tools medical procedures, well selected parameters of machining, and the highest level of quality control in order to obtain the necessary surface finish and dimensional precision.

Dental Equipment and Instruments

Dental is an industry that uses precision-machined parts extensively as either a cutting tool or restorative device. Prominent examples are dental probes, scalers, mirrors, handpieces and orthodontic appliances, which must be made with an extraordinary level of surface finish and dimensional accuracy drug delivery systems most commonly used materials. The manufacturing of custom-made prosthetics, crowns, and implants through CNC machining also find its way into modern dental manufacturing.

Digital dentistry has transformed this discipline making it possible to have direct stereolithography of dental restoration through the utilisation of digital impressions. This combination of the digital scanning, CAD and CNC machining has enhanced the accuracy and efficiency of dental practices very much.

Advanced CNC Machining Technologies for Medical Applications

Wire EDM (Electrical Discharge Machining)

The wire EDM technology is invaluable in the medical manufacturing process because of its precise tolerances, which are exceptionally tight, as well as high surface finishes tight tolerances. It is a non-contact metal machining in which an electrically conductive probe is used to cut into conductive materials with a high level of precision to produce very fine tolerances sometimes less than 0.0025mm.

Wire EDM especially finds application in producing surgical cutting tools, complicated geometries of implants and precision medical instrument manufacturing. It generates little heat-affected areas and can also cut hardened materials that could be cumbersome to cut through their traditional processes of machining quality assurance.

5-Axis CNC Machining Systems

1. The five-axis CNC machining is the highest technology in precision manufacturing, and it allows intricate three dimensional shapes to be produced as multistage setups. By use of this technology, cutting tools can approach workpieces at any angle virtually, and multiple setup is not necessary, and the manufacturing errors are reduced precision components.

Five-axis machining: complex geometries of the implants, the surgical instruments with the intricate components, and components of medical devices with compound angles are crucial to create in medical applications critical components. The technology saves a lot of time in the process of manufacturing, enhancing accuracy of parts and quality of surface finishing.

Swiss CNC Machining

Swiss CNC machining technology has the perfect technology of manufacturing small but precise parts as seen in the medical equipment. Sliding and guide bushings are incorporated in these types of machines; they allow support of longer, slender parts very well during the machining processes.

Swiss CNC machines are used in the medical industry to make components like bone screws, components of dental implants, fittings of catheters, and other small precision parts, used in medical electronics. Swiss machines have the capability of carrying out complicated processes in single set ups due to the simultaneous multi-axis ability.

Multi-Spindle CNC Systems

The use of multi-spindle CNC systems is beneficial in manufacture of high volumes of medical components. They are capable of carrying out various machining processes at once and as such, they enhance productivity by a very great margin without compromising on precision levels.

In medical manufacturing, the multi-spindle systems are used to manufacture parts which are standardized medical components: bone screws, surgical fastener, and other threaded parts employed in the medical assembly. One product that the technology is especially useful in serving is the high-volume needs of disposable medical products.

Material Selection for Medical CNC Machining

Biocompatible Metals

Titanium and Titanium Alloys

Titanium alloys, specifically Ti-6Al-4V (Grade 5) and Ti-6Al-4V ELI (Grade 23), have become the best medical implant, because of its out-of-this-world biocompatibility, strength-to-weight balance, and corrosion resistance. Such materials are frequently employed to make joint replacements, spinal implants, dental implants and cardiovascular device.

Workpieces made out of titanium alloys need to be machined with special cutting tools, optimized cutting operations, and efficient coolant systems in order to control heat production and wear of the cutting tools. The nature of the material that it tends to work-harden during the machining process requires sharp cutting and feed rate.

Medical-Grade Stainless Steel

Grade 316 L stainless steel and 304 L stainless steel possess good corrosion resistance properties, strength and are easily sterilized thus their use in the medical industry is popular. Surgical instruments, orthodontic appliances and components of many medical devices are usually made using these materials.

Medical-grade stainless steels must be machined carefully with respect to their work hardening behaviour and choice of suitable cutting tool geometries to ensure excellent surface finishes, and dimensional accuracies.

Cobalt-Chromium Alloys

The alloys of cobalt-chromium have excellent wear resistance, and biocompatibility, and are therefore suitable in areas of high stress like the replacement of joints and dental implants. These materials are highly machining (e.g., because they are so strong and because they work-harden).

To machine Cobalt-chromium alloy, rigid-machine setups, sharp cutting tool, as well as optimal cutting parameters, and surface finish needs are warranted to minimize work hardening.

Medical-Grade Plastics and Polymers

PEEK (Polyetheretherketone)

PEEK has found wide use in the medical industry because of its strong and very diverse biocompatibility, chemical durability, and mechanical properties that are highly comparable to the bone. The material is used in spinal implants and trauma implants and the parts of many medical devices.

The polymer PEEK lacks melting tolerance and stringent requirements of cutting tools, surface finishes and parameters during CNC machining. Poor thermal conductivity of the material requires great attention to heat during machining processes.

Medical-Grade Polyethylene

Ultra-high molecular weight polyethylene (UHMWPE) has been frequently exploited in the joints replacement procedure given its formidable wear performance and biocompatibility. The material is regularly used as a non-acetabular shell in hip replacement and the tibial insertion in a knee replacement.

UHMWPE needs a sharp cutting tool and parameter optimization to avoid deforming that material and obtain surface finishing quality. The property of the material to produce a static charge when machined needs the proper process of handling such materials.

PTFE and Fluoropolymers

PTFE and fluoropolymers are chemically inert and biocompatible and so they may be applied in many different aspects of the medical field such as catheters, seals, and gaskets. The materials offer special machining problems associated with low strength and propensity to deform with cutting.

Quality Control and Regulatory Compliance

ISO 13485 Standards

ISO 13485 is the global mechanism of quality management systems applied in the manufacture of medical devices. This standard involves elaborate documentation, traceability and quality control all through the manufacturing process.

CNC machining operations related to medicine should have efficient quality management systems, which guarantee the consistency of the products, have traceability, and can meet the regulatory requirements. This involves process documentation including documentation of all processes followed, routine calibration of measuring instruments and extensive inspection procedures.

FDA Regulations and Compliance

Food and Drug Administration (FDA) has been regulating medical devices in the United States using a holistic approach which involves classes of the devices, pre-market approvals as well as quality systems. Manufactures of medical devices are required to adhere to the Current Good Manufacturing Practices (cGMP) and ensure proper detailed documentation of manufactured products.

The CNC machining process should use validation practices, control procedures and documents that meet the FDA guidelines. This involves process parameters, process validation studies as well as keeping extensive batch records.

Validation and Documentation Requirements

The process of manufacturing medical devices demands a lot of validation and documentation to prove the process capable and consistent in terms of a manufactured product. These comprise Installation Qualification (IQ), Operational Qualification (OQ), Performance Qualification (PQ) procedures with regard to CNC machining apparatus.

Documentation requirements are characterized by a large COVID 19 instructions, work parameters, inspection methodology, and corrective actions. All the documentation should be stored on the controlled systems that guarantee the version control and traceability.

Surface Finishing and Post-Processing

Passivation Treatments

Passivation A stainless steel component used in a medical application must be properly cleaned and passivated and a titanium component used in a dental application must be passivated as well. This is a chemical composition of removing the surface contaminants and augmenting the inherent oxide film, which increases the corrosion resistance as well as biocompatibility.

It is necessary the good control and validation of passivation process to guarantee reproducibility. This also involves confirmation of the chemical concentrations, treatment periods as well as cleaning up measures after treatment.

Electropolishing Processes

Electropolishing offers the best surface finishing of medical component properties by surgically ablating the surface by means of controlled electrochemical dissolution. It enhances the smoothness of surfaces, microscopic defects are eliminated and this process increases the corrosion resistance.

Specific surface roughness values and properties often demanded with medical applications cannot be obtained by any other means but electropolishing. The parameters of the process should be well regulated and validated to indicate reliability in terms of production side by side.

Sterilization Compatibility

Medical components have to be suitable with different ways of sterilization such as steam autoclaving, ethylene oxide gas, gamma radiations, and the electronic beam sterilization. Materials finishes and treatment should be chosen so as to endure repeated sterilization cycles with no degradation.

Depending upon the type of sterilizing method desired, specified surface treatments should be chosen with care since particular effects on the property of the surface and its dimensional stability may result.

Precision Tolerances and Measurement

Dimensional Accuracy Requirements

Some medical parts may be extremely dimensionally sensitive and even micrometers of deviation might not be tolerated. Any of these tolerances needs a precise consideration of machine tool tolerance, thermal stability, and measurement error.

The statistical process control techniques are important in the dimensional accuracy or process capability monitor. This involves calibration of measuring equipment in regular basis and use of proper sampling plans.

Coordinate Measuring Machines (CMM)

The desired accuracy, repeatability needed in the inspection of medical components is provided by the coordinate measuring machines. The latest CMM systems use high technology probes and software that allow auto inspection of intricate shapes.

The CMM inspection programs should be created and justified to provide the correct measuring of critical dimensions and geometrical tolerances. To ensure high accuracy in measurement, CMM systems should be regularly calibrated and maintained.

Statistical Process Control

Monitoring of CNC machining should rely on statistical process control (SPC) techniques to maintain the quality of its task. Monitoring systems in terms of control charts, capability studies and monitoring of the process assist in detecting the differences in the process before it can lead to production of products that do not meet requirements.

The SPC should be implemented with special care over the choice of control parameters, determination of control limits and training of the staff on the application of statistical techniques and interpretations of control charts.

Custom Medical Device Development

Prototyping Services

Medical products development applications need to have rapid prototyping options that will facilitate verification and testing during the design process and verification in clinical trials. CNC machining offers precision and material considerations in the manufacture of functional prototypes that match the final manufacturing parts.

The prototyping services should be dynamic to cope with design alterations without straying the needed precision in medical applications. This also involves quick turnaround and capacity to utilize broad variety of medical grade materials.

Design for Manufacturing (DFM)

In successful medical devices design, Design for Manufacturing (DFM) is very essential. Cooperation between design engineers and manufacturing specialists early in the design process can find possible manufacturing difficulties and more efficiently optimize designs in making it producible.

DFM factors are the material selection, geometric tolerancing, surface finish specifications and choice of manufacturing processes. When DFM principles are implemented properly, they can drop the development time and the manufacturing costs drastically.

Scalability from Prototype to Production

The manufacturers of the medical devices need to ensure that they can grow in scale concerning very small till the full production run in terms of quality and regulations. This necessitates that there be processes of manufacture that are strong and capable of being done repeatedly through various production quantities.

Scalability involves the selection of the equipment, characterization of the process, management of quality controls and supply chain. Scaling is always a well-planned process that involves validation of every production step.

Cost Optimization Strategies

Material Utilization Efficiency

Effective use of material is highly significant in management of manufacturing costs in medical CNC machining. This involves the optimization of part orientation, reduction of waste products and recycling of various precious products like titanium.

The approach to material efficiency should be focused on special needs of medical production, particularly traceability requirements (printing and etching) and prohibition of recycled materials in some parts.

Process Optimization

Process optimization entails a progressive assiduous optimization of machining parameters, tool choice and machining setup protocol to attain optimal efficiency with quality. This involves application of the lean manufacturing concepts and automation as may be suitable.

There has to be a balance of cost reduction and quality needs as well as requirement to meet the regulatory body. According to medical device quality systems, all the changes in the processes need to be justified and recorded.

Volume Production Strategies

The production of medical devices in volume needs special tactics in order to reach the aim at the cost-effective production keeping it on the same level with the quality. This can consist of dedicated lines, and automatic handling systems and also statistical quality control.

Volume production initiatives need to take into account the particular requirements of drug manufacturing such as lot traceability, validation of processes and regulatory affairs.

Technology Integration and Automation

CAD/CAM Integration

The CAD/CAM-enhanced CNC machining of the present-day medical world cannot do with the integrated CAD/CAM machining system that allows the smooth passage of the design information to the manufacturing procedures. Optimizing tools, simulation and automatic generation of tool paths are aspects that these systems offer.

Design and manufacturing integration enhances precision, minimizes the lead time, and fast responsiveness to design alterations. This is very crucial in cases of development of medical devices where iterations may occur in design.

Real-Time Monitoring Systems

The use of the real-time monitoring systems will allow finding the problem and the process change immediately because of constant feedback on the history of machining. Examples of parameters which can be monitored in these systems includes cutting forces and spindle vibration among others/dimensional accuracies.

Quality control procedures and documentation systems must be part and parcel of monitoring systems so that there is proper response to the variations and maintenance of compliance to the regulations.

Predictive Maintenance

Predictive maintenance systems analyze the data and apply machine learning to predict failure before it has happened. This runs down the occurrence of unplanned downtimes and brings in a stable quality of the products.

It is important to note that installation of predictive maintenance in the medical manufacturing industry should be sensitive to the sensitivity of the medical manufacturing and how equipment failure is likely to affect the patient.

Traceability Requirements

The medical device laws mandate the complete traceability across the supply chain that spans the raw materials to the finished goods. This encompasses material certification tracking, manufacturing record and also commissioning records.

Traceability systems should be able to provide quick recalling and need to combine with customer quality systems. The use of electronic tracking systems and serialization is becoming much-needed by the regulations.

International Shipping Considerations

Delivery of medical devices overseas may involve adherence to numerous regulatory needs in terms of export license, customs paperwork as well as regulations that medical devices have to satisfy in respective countries.

Experienced and specialized logistic companies that understand the medical device regulations may carry out compliant international transportation at minimal costs and delays. This will comprise documentation, packaging as well as handling of medical devices.

Emerging Technologies and Future Trends

Additive Manufacturing Integration

New opportunities to produce medical devices are opening up as the additive manufacturing (3D printing) and traditional CNC machining combine. Hybrid manufacturing systems have the potential to incorporate the work freedom of additive manufacturing and precision machining of CNC machines.

The given technology is especially useful in requirements of complex shapes, personalized implants, and the creation of low-volume specialty implementation. The integration has to take into account material characterizations, process validation, and regulatory needs.

Artificial Intelligence Applications

Machine learning and artificial intelligence are becoming used extensively in medical CNC machining to optimize the process, predict quality and predictive maintenance. These technologies can study huge amounts of data and see trends and focus on optimization of manufacturing parameters.

AI software should be verified and checked as medical devices. Its implementation must take into account the security of data, an algorithm verification, and a regulatory proof.

Nanotechnology in Medical Manufacturing

New surface treatments and property of materials support an improvement of the performance of medical devices possible due to nanotechnology. These include nanostructured surfaces which enhance osseointegration, and antimicrobial coatings which lower the risk of infections.

The medical manufacturing that involves nanotechnology implementation needs special equipment, validation procedures and process controls. Nanotechnology-enabled devices in the medical field still have pathways of regulation developing.

Environmental Sustainability

Green Manufacturing Practices

The occurrence of environmental sustainability is also gaining much ground in the field of medical manufacture. This encompasses manufacturing of energy-efficient products, reduction of waste material, and clean materials.

Sustenance practices have to be weighed against the quality principles and regulatory standards. The environmental effects of the manufacturing decisions may be assessed by using the life cycle assessment tools.

Waste Reduction Strategies

The waste streams produced in medical manufacturing are metal chips, cutting fluid, and packaging materials. It is particularly being accomplished by waste reduction strategies that are much effective in environmental impact and cost of manufacturing.

The core concern of waste reduction must take into consideration special needs of medical manufacturing such as prevention of contamination and legal prohibition against recycling of materials.

Circular Economy Principles

The principles of the circular economy deal with designing products and processes in order to recover material and reuse it. This strategy is able to save costs in the material and the environmental damage as well as retain the standard of quality.

The use of circular economy principles in medical manufacturing deserves thorough attention to the aspects of regulation and implications on patient safety.

Training and Workforce Development

Skilled Technician Requirements

Medical CNC machining needs very qualified technicians with a proper knowledge of manufacturing technology and knowledge of the medical device laws. This entails machining processes knowledge, quality control, and regulatory compliance.

The educational initiatives should cover both regulation and technical expertise. Lifelong learning is required because of the ever-changing technology in addition to shift in regulatory requirements.

Regulatory Training Programs

Manufacturing of medical devices needs special education on regulations, the quality system, and documentations. This training should be periodically revised in order to reflect shifting laws and other industry norms.

According to the medicial device quality systems training programs should be documented and validated. To ensure compliance, regular revising and retraining are required.

Technology Advancement Education

A fast development of the manufacturing technology demands constant learning and training of manufacturing employees. This covers new machining technologies, software systems and quality control procedures.

The training on technology should be balanced by regulation and quality system procedures. New technologies have to be implemented with great care so as to be validated and documented.

Global Market Considerations

Regional Regulatory Differences

Regulations of medical devices are substantially different among countries and regions. Manufacturers should know and execute any individual market requirement in each of the markets they are going to sell their products.

Manufacturing treatments, Document handlings, and quality controls might be regulated differently in different countries and thus be impacted as a result of regulatory variations. Multinational production firms ought to institute mechanisms that support diverse regulation systems.

Market Access Strategies

To achieve an effective market access, one must know the regulatory flows, clinical, and reimbursement networks of target markets. Such knowledge should be used in deciding manufacturing choice, designing the quality system.

The market access strategies should be based on the whole product lifecycle which includes product development, commercialization and post market surveillance.

International Standards Harmonization

International cooperation seeking harmonization in standards of medical devices exists and bodies like International Medical Device Regulators Forum (IMDRF) are engaged in harmonizing requirements.

Instead, harmonization efforts can make it easier to manage international production and entry into the market, although the manufacturers should keep an eye on the changing standards and requirements.

Risk Management in Medical CNC Machining

Process Risk Assessment

The production of medical devices needs thorough risk evaluation in order to detect possible dangers and establish satisfactory controls. This encompasses evaluation of manufacturing procedures, equipment and people.

Risk evaluation should be done based on the established protocols like ISO 14971 and should be periodically revised due to the change in the process, machinery, and regulatory policies.

Quality Risk Management

Quality risk management consists in finding out possible quality flaws and applying preventative strategies. This involves measurement of process capabilities, supplier quality and uncertainty of measurements.

Quality risk management should be incorporated into the total quality management systems, and it should be periodically revised and re-adjusted in accordance with the experience as well as quality information during the manufacturing process.

Supply Chain Risk Mitigation

Some of the risks that affect medical device supply chain encompass failure of suppliers, natural disaster, and geopolitical risks. Risk-mitigation measures need to be solid to maintain a supply chain.

Supplier diversification, management of inventories, and alternative sourcing arrangements satisfy the strategic risk mitigation approaches. Strategies have to be striking with cost effects and regulatory issues.

Conclusion

Medical CNC machining commotion is also the future where high technology integration in manufacturing machines, sustainability of production and high-level compliance solutions are integrated. With the further evolution of the healthcare market, manufacturers should respond to new demands but do not lose precision and quality necessary to ensure the safety of patients. Organizations such as Leading Edge are important in enhancing medical device supply chains worldwide because they facilitate the delivery of important healthcare products to patients in an effective and safe manner. Investments in technology, training and quality systems will continue the revolution of innovation and enhancement of patient care in all corners of the globe and medical CNC machining will be a major facet of any modernized healthcare service delivery system.