Meta Description: MJF vs SLS: overview of the hp multi jet fusion and 3D printing technologies differences. Get to know the prices, materials, uses, and the most ideal technology to use in your manufacturing venture, which often includes achieving finer feature resolution .

The 3D printing world transformed the face of manufactures, but two technologies can be considered the leaders in the powder-bed fusion process: Multi-Jet Fusion (MJF) and Selective Laser Sintering (SLS). Both the technologies have revolutionized the prototyping and production in industries, however, it is imperative to understand these key differences in the technologies to conduct a rational decision making on manufacturing projects you may want.

Understanding Multi-Jet Fusion (MJF) Technology

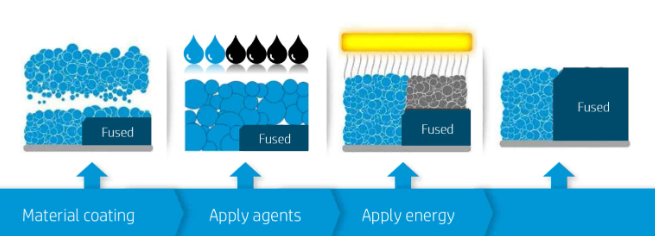

Multi-Jet Fusion is the latest drastic innovation in additive manufacturing technology by Hewlett-Packard in the year 2016. The MJF 3D printing method makes use of the fusing agent applied to a bed of a powder material, which is added with detailing agents to regulate the fusing process at the boundary, and finally, it uses infrared light source to fuse the powder particles and form 3D objects. The new technology enables a homogenous heating and printing process for high performance materials .

The MJF process starts by coating a thin layer of the powdered material [usually nylon] followed by heating to slightly below its sintering temperature. The sections where the part solidifies are fused by high-level printheads, which sometimes require support structures. , and various detailing agents are located along the edges to form sharp clean boundaries. Lastly there is the process of infrared energy being waved over the whole layer which makes the treated areas become bonded together.

Exploring Selective Laser Sintering (SLS) Technology

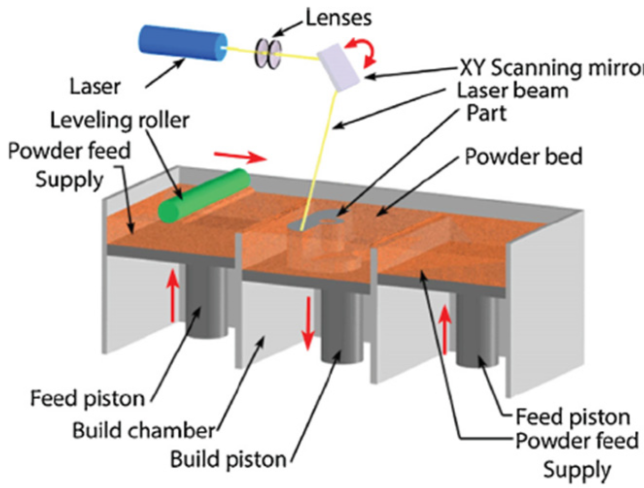

Selective Laser Sintering constitutes one of the main pillars of the 3D-printing technology which was invented by Dr. Carl Deckard and Dr. Joe Beaman in the mid 1980s. SLS melts and then fuses powder grains together by utilizing a laser that in most instances utilizes a CO2 laser in tracing out consecutive cross-sections of a part and sintering powder particles as the device moves. The technology is mature and has been used as a durable alternative in different manufacturing operations.

Through the SLS process, a thin layer of powder is spread on the build platform after which the material is selectively sintered with the use of a laser beam following the cross-section of a part. When a layer has been built, the build platform is lowered, then a layer of powder is added. This layer by layer method proceeds until the whole part is built, which can lead to smooth surfaces .

Key Technological Differences Between MJF and SLS

A basic distinction between the two technologies is on how they apply energy. With SLS printing, you weld each cross-section point by point whereas with MJF it is more linear. This difference influences many facets in the printing process, including the isotropic properties and characteristics of the material ranging between the speed and material characteristics.

The laser beam on SLS is concentrated, shifting the powder bed melting point per point. The method offers good control of energy forces yet may leave thermal build-ups which influences property of parts. MJF on the other hand takes a wide spectrum infrared heat source and couples it with chemical agents which have the effect of creating more uniform heating on an entire layer.

Material Compatibility and Options

One of the most important distinctions between MJF and SLS technologies is implied by material selection. SLS has a wider range of material to use over MJF including many that can be stained and MJF produces better isotropic material with a touch higher print resolution. This variation influences the aesthetic and operational capabilities of both the technologies, particularly in terms of dimensional accuracy .

SLS can accept a larger variety of materials such as a variety of nylons, thermoplastic polyurethane (TPU) as well as polypropylene and even metal-filled composites. The maturity of the technology has enabled a vast amount of material development, and carbon filled and aluminum filled nylons to improve the mechanical properties.

Though less versatile than its material variety, MJF finds its strongest application in processing a material more commonly used such as nylon 11 and 12 with high consistency. An increase in control of the material properties is made by a capable technology that fuses the material at the molecular level, which gives the produced parts higher mechanical properties.

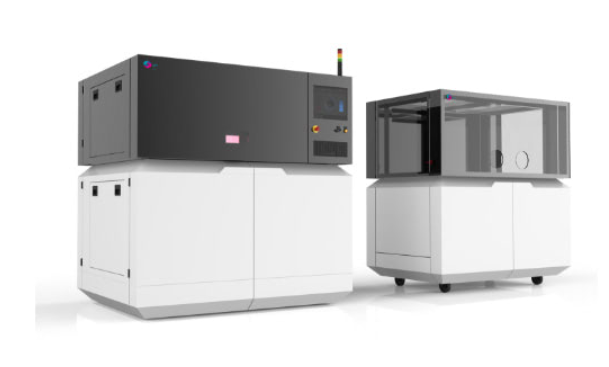

Build Volume and Production Capabilities

There is a major difference between production capacities of these technologies. The build volumes on SLS machines are also bigger than the MJF machines when it comes to some variant of material, including the glass-filled nylon, where SLS can print more nested parts per run. This is the biggest benefit of SLS and specifically used in medium sized functional parts and large productions.

With the largest SLS machines the build volume can reach 660 x 380 x 580 mm, whereas MJF machines are usually limited to 380 x 280 x 380 mm. This size disparity affects the production efficiency directly particularly when the parts are of larger size or in cases of high volume production runs.

MJF however counterbalances this with its removable build volumes, which enable parts to be cooled outside of its printer as the machine readies itself to work on a newly-set job. This aspect results in the increased productivity due to less time used in between builds.

Surface Finish and Post-Processing Requirements

Both technologies make parts with rough, matte surface finishes which are both characteristic but also differ slightly in terms of quality and available post-processing choices. SLS is successful in providing spacious details with a high level of accuracy, and the layering of the powder causes the result to give strong parts with a very good structural strength.

MJF usually gives the surface finishing quality that is slightly higher because of its more homogenized heating process and a more precise print resolution of 80 microns against 120 microns associated with SLS. The detailing agents also enhance better definition of edges and transition of surfaces used in MJF.

It is in post-processing that both technologies share the advantages of shot blasting, media tumbling and chemical vapor smoothing. All this can be used in converting the raw or initial printed surface into a sealed, semi-gloss finish with end use applications.

Mechanical Properties and Part Performance

The printed parts mechanical properties are also quite different between MJF and SLS because these two materials have different heating processes. Both SLS and MJF are similar in terms of the strength of the part, although MJF makes it slightly better since it is more isotropic. In this isotropy, MJF parts have uniform mechanical properties that are the same (irrespective of load direction).

The infrared heating by MJF produces more homogeneous temperature distribution of the powder bed with product parts that have about 98 percent isotropic outcome. The property also qualifies MJF parts to be used in instances that demand uninterrupted mechanical behavior in any direction.

Because of the adverse impacts of the laser, which provides only local heating, the parts made of SLS are rather anisotropic, but they retain structural properties, which allows for complex geometries . The sequential fusion process may produce small variations of material density and of molecular orientation resulting in directional variations in mechanical properties.

Cost Analysis and Economic Considerations

When comparing costs of MJF and SLS several factors need to be taken into consideration such as cost of materials, operating machine and volume of products. Both of the styles have a broader range of similar costs in terms of printing and time taken, where MJF is more cost-effective than its counterpart when large quantities of work are required. Economic strength of any technology is greatly reliant on application specific and production demands.

The usage of material is significant in total expenses. MJF has the offer of better powder recyclability up to 80 per cent of powder can be reused instead of SLS that reuses a maximum of 30 per cent to 50 per cent of its powder. Such difference has its significant effect on cost of materials, particularly by use of high volume production, especially regarding unused powder .

The cost of labor also differs in different technologies. The modular build chambers and automatic powder handling systems of MJF also eliminate the manual interference, whereas SLS is more labor-intensive and would need more handling of the powder.

Application-Specific Recommendations

Prior to settling on MJF or SLS, factors that determine the choice are mostly based on the planned use and special needs. The compact parts, which need to be functional, are appropriate to be produced with MJF, whereas the visual prototypes and functional parts, which are not large, would be rather appropriate to be done with SLS. The rationality of such application specific benefits for rapid prototyping can assist in choosing technology.

MJF performs the best in the production of functional parts that need consistency in their mechanical properties, including automotive parts, medical parts and other consumer products. The isotropic nature and good surface finish of the technology makes it suitable in end-uses where robust mechanical properties and performances may be of great concern.

SLS is the most popular prototyping method and can be used where colour range needs to be considered. Most features of the grating are visible to help in the prototyping of the design and testing. The SLS parts can also be dyed in several colours. Also, SLS bigger build volumes can be used on architectural models and large-scale prototypes.

Future Developments and Industry Trends

Both technologies are still being refined and materials, speed and capabilities are still being developed. HP is constantly increasing the material range of MJF and is rolling out new composites and polymers to increase the range of applications selectable high dimensional accuracy. In the meantime, the production of SLS and several industrial technologies is specialized in terms of increasing the speed, accuracy of the process, and build volume.

Both technologies will present a better process control and predictive maintenance, which is possible due to the implementation of artificial intelligence and machine learning. The developments are bound to enhance the consistency of part quality and also lower manufacturing expenditures both on platforms.

Conclusion

Whether to use MJF or SLS is influenced by certain unique project demands, such as the part size, raw material requirements, product volume, and budget functional testing. MJF would be a higher performing material, recyclable, and have the best finish on functional parts, whereas SLS would have more material options, high output build space, and fewer uncertainties that it cannot be trusted to work over small runs of prototypes. The two technologies have carved their niche in the 3D printing world, with each technology having a different pain point in the markets and production requirements multi jet fusion process.