Meta Description: All you need to know about threaded holes in manufacturing; the process of tapping, thread forming methods, uses and recommended practices, including how to create internal threads and creating threads . The essentials guide to engineers and manufacturers who want precision machining services.

Threaded holes Threaded holes are essential elements used in the present-day setting of manufacturing and engineering and used as anchors by numerous mechanical arrays around the globe. Whether its attachment of the automotive parts to aerospace systems, threaded holes provide us with secure methods of fastening things with a fastener. that keep our technological world intact. To engineers, manufactures and anyone interested in mechanical design, it is necessary to understand the mechanics of the threaded holes, how they are created, usually using a tap, and their usage.

What Are Threaded Holes and Why They Matter

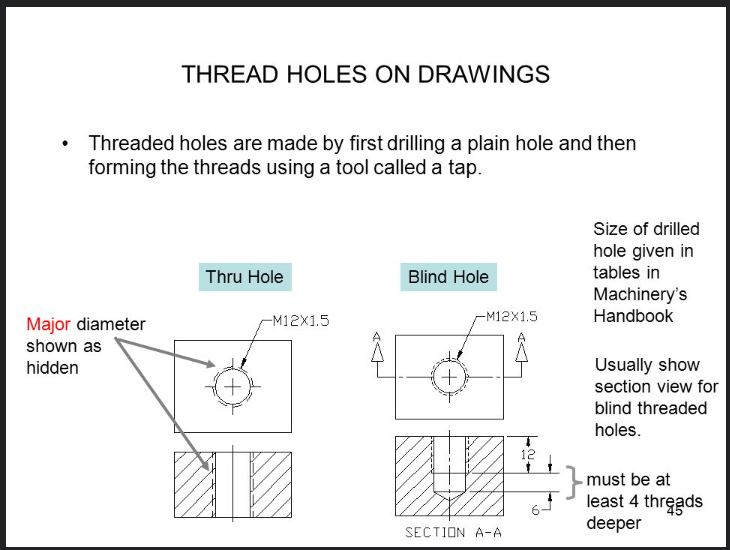

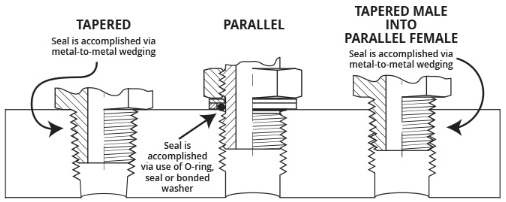

Threaded holes are tubular openings in a material that has an internal spiral groove to accept a threaded fastener e.g. screw, bolt or stud, including tapped holes . There are several processes of creating the holes and the most frequent of them is tapping, which begins with a tap drill . The internal threads receive mechanical advantage by the helical form, making them easy to affix and having the capacity to implement a high amount of clamping forces.

All it takes is much more than plain fastening. They may allow taking apart and reassembling parts, offer adjustable attachments and may spread out loads over wider surface areas after drilling . Threaded holes in manufacturing environment are usually the last machining process to be done done and they need to be machined with much care and precision to fit well and work properly.

Understanding the Tapped holes Process for Thread Creation

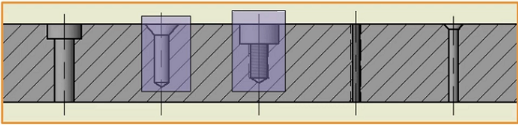

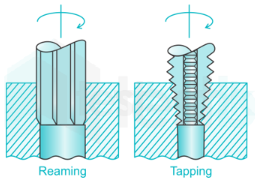

Tapping is the method of forming threads within a hole to accept a screw or a bolt application so tapping hole is simply a hole that is cut with an internal Thread. This process of tapping starts by drilling a pilot hole with a specific drill size hich is a little narrower than the major diameter of the threaded fastener required. This pre hole serves as a basis of thread development.

The tapping activity is the process that is carried out using a special cutting device, which is similar to a drill bit and is called a tap and has sharp cutting edges which are positioned in a helical shape. The tap moves forward into the pilot hole, and threads the inside as it rotates. The operation of cutting implies the necessary control of the speed, feed rate, and lubrication that will avoid a break during threading when using a tap and ensure the quality.

All this has been modified by present day CNC machining centers which have effectively changed the way tapping is done, particularly with cnc machining which have accurately given control of these factors. Automated tapping ensures less possibility of error in the human element and consistency in thread quality run to run. Nevertheless, manual tapping finds application in the miniature productions that require little setup time to justify the use of the automated tapping routines, while other methods may be used in the production process of prototypes, repairs and during small production runs.

Types of Taps and Their Specific Applications

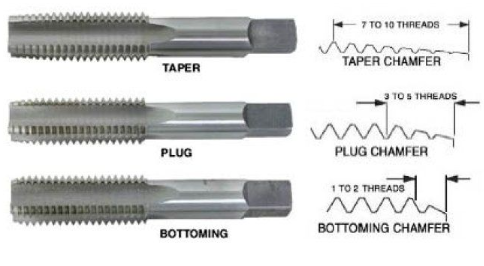

Knowledge in the various types of taps is important in selection of the appropriate tap to be used in certain applications, especially when dealing with screw threads . The hand taps are crafted to be manual and have very good feel and control and have been very renowned to be used in prototype work and field repairs. They are not, however, generally as precise, or effective, as machine taps applied in CNC work.

In the case of the blind holes, a bottoming tap is the best choice, yet you can decide to begin with taper tap then switch to thread forming taps such as bottoming tap to create clearer threads with threaded inserts for added strength . Taper taps have such leads and are useful in beginning the threading process but bottoming taps have little taper and can cut nearer the bottom of blind holes.

Spiral point taps are through hole taps and aids in chip evacuation by forcing the chips forward into the hole. Spiral flute taps on the other hand work better on blind holes since they draw the chips back out and away of the hole. The chipless compression tapping allows the taps (thread forming taps) to offer more strength to the thread and more thread life since there is reduced possibility of the thread breaking, which helps to avoid issues like cross threading .

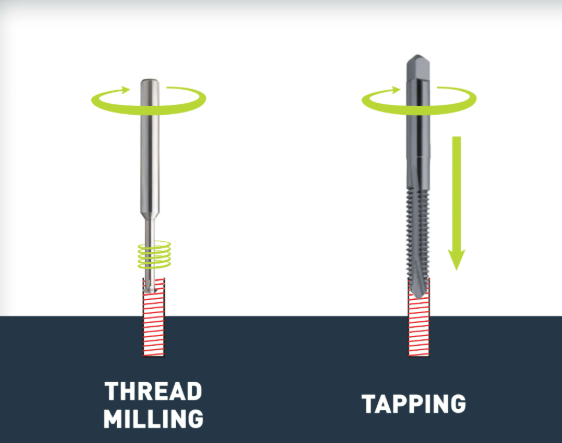

Threading vs Tapping (Taper tap): Understanding the Terminology

Although most people use it interchangeably, the term threading and tapping requires unique stance in the terminologies of manufacturing processes. To create the external threads on the cylinder of a screw, a bolt or any other element to be fastened, creating threads is carried out, but when it is necessary to form internal threads into a hole, threading is called tapping, depending on the thread type required .

Threading is a general terminology to denote the situation when threads are made in any direction with different kinds of cutting tools. With this expanded meaning, several processes are covered such as tapping (used to cut internal threads), die cutting (used to cut external threads), thread milling and turning threads using lathes.

This difference is significant in communicating with the manufacturing partner or in specifying requirements on the engineering drawings. A hole may be threaded by tapping with a tap, or by thread milling, or by other means, but counted as a threaded hole; or may be a tapped hole whose metric threads have been cut specifically with a tap tool.

Thread Standards and Specifications

Thread standards This is achieved through thread compatibility and interchangeability between items produced by other companies or at other factories. The two most universal standards are Unified Thread Standard (UTS) most commonly in North America; and ISO metric threads worldwide. These standards define thread pitch, large diameter, small diameter and thread profile form.

The designation of threads is very important in the specification and the manufacture of threads. Each tap is identified by a standard design that has the following details; Nominal Size (Threads/Inch) | Thread Form Designation | Material Tap is Manufactured Out of | Tolerance Value of Pitch Diameter. This knowledge helps in the appropriate selection of taps based on thread sizes in relation to certain fastener applications.

Thread tolerances The tolerance between the male and female threads falls under two classes which are loose tolerances at which it is easy to assemble and tight tolerances which is meant to be as strong as possible. The most common is the Class 2 threads, which are usable with general applications and offer balance between holding power and easy assemblies.

Materials and Their Impact on Threading Operations

The choice of the material has a major influence on threading and tool life. On average, aluminum alloys are surface tap friendly because it is relatively soft and offers great chip evacuation capabilities. But caution should be exercised to avoid welding and galling of chips especially in some grades of aluminum alloy.

The threading characteristics of steel materials differ very considerably. Low-carbon steels are easy to tap but could generate stringy chips that tend to clog tap flutes. The harder ones and stronger alloy and high-carbon steels are more difficult. Stainless steels have distinctive issues because they are work-hardening and they produce heat when cut.

Taps are not most effective on hard or brittle material, which include hardened steel. Such kind of materials, along with the presence of metal shavings, are able to wear out taps easily rendering them useless in the making of good threads. Negative gas pressure In these situations another technique such as thread milling or threaded inserts can be used to mitigate tap breaking .

Threaded Hole Design Considerations

Designing threaded holes can be counted as one of the critical factors which impact the manufacturability and performance, particularly focusing on certain materials . Length of thread engagement, along with correct thread sizes, and its depth is key where too short engagement results in less strength, and a proper clearance hole is crucial . and too long engagement is unnecessarily expensive without correspondingly benefiting strength levels. As a typical rule the thread engagement restraining force will be maximum at a length of 1.5 times bolt diameter correct size.

The spacing between holes as well as the edge distance should also be addressed to avoid failure of the material when installing or servicing. Inadequate edge distance may result in thread stripping or fracturing of the material and inadequate spacing between holes may produce interference when tapping.

Strength is deficient and also the feasibility of manufacturing threaded holes due to the presence of wall thickness around. Thin walls can not always afford enough material to achieve full thread engagement, very thick walls can engage full depth with special tapping equipment or methods needed.

Quality Control and Inspection Methods

Threaded holes quality control will include combination of inspection techniques to make sure that quality is met to specification. Go/no-go thread gauges give a rapid check that threads are within limits of tolerance levels. Such gauges are made of a go end which is supposed to readily pass into to satisfactorily sized holes and a no-go end that is not supposed to pass into sound holes.

Thread pitch gauges may be used to ascertive thread pitch and profile and optical comparator systems used to thoroughly analyse thread geometry. Thread measurements can be measured with great accuracy as in critical applications using coordinate measuring machines (CMMs).

Visual inspection is still needed to catch a defect related to torn threads, incomplete threads, or other types of contamination. Adequate lighting and magnification enables an inspector to detect possible problems that may cause a delay in assembly or operational jams.

Common Threading Problems and Solutions

The quality of thread may be poor because of many reasons and special solutions should be provided. The reason that torn or rough threads occur is usually that the taps are worn out, cutting speed was wrong, or bad lubrication. They help to avoid these issues with regular tools inspection and replacement and proper cutting parameters.

Tool Breakage: Taps break more easily in comparison with other threading tools. Faulty taps may be a nightmare to a machinist since they may prove to be hard to remove. To prevent the breakage of tap following parameters of cutting and the adequate cutting of the pilot holes sizes and cutting chips must be considered.

Excessive or undersized threads are usually caused by either improper choice of a tap,ད attributable to worn tap, or poorly adjusted tap machine. Thread accuracy is done through close checking of tap specifications and the routine calibration of equipment.

Alternative Threading Methods

Although tapping is the most popular statistical technique of making threaded holes, there are other methods that bring promises in certain scenarios, allowing for the creation of own threads . Thread milling involves interpolating thread form with a special end mill, and has the advantage when large diameter threads, strict requirements on hard materials, or tap breakage is an unacceptable scenario occur.

Thread forming (cold forming): Where the threads are not cut and threads are formed by displacement of the material and therefore more threads are strong and have higher fatigue resistivity. It is a good process to use with ductile materials although it uses more forming force and specialized equipment.

Another alternative is threaded inserts, especially where the material being fastened is soft, such as aluminum or plastic, where thread strength would otherwise be inapposite. Each of these inserts, helical coil inserts, solid inserts and expanding inserts provides a certain advantages based on the requirements of the application.

Applications Across Industries

Threaded holes usage is practically in all industries and each industry has its own particular requirements and issues that may be encountered. Threaded holes in the manufacturing of automobiles are needed to fasten parts of the engine to detailing body panels, especially when dealing with soft materials, depending on the thread type required . to various features of automobiles, which needs large manufacturing capacity and quality consistency.

An aerospace application needs the highest level of quality and traceability, which in some cases requires custom processes and paperwork. The weight critical properties of any aerospace component also impetus the use of hi-tech materials and threading to reduce weight in order to achieve strength.

Consumer electronics are very thin tall thread holes with tight tolerances are needed in demanding materials such as titanium or exotic alloys. Being of small scale, this kind of operations necessitates special equipment and utmost accuracy.

Future Trends in Threading Technology

Threads, where the critical features that enable the effectiveness of the cutting tool in threading technology to exist or not exist when engaging with a fastener. , have all been developing in terms of material used, coating and even manufacturing methods. Higher tool coatings increase tap life and allow increased cutting speeds, and better tool geometries increase chip evacuation and cut down cutting forces tapped holes require threading techniques.

Additive manufacturing opens up new possibilities and problems to threaded holes. Although certain additive processes are able to make threads simultaneously as the part is manufactured, post-processing steps such as tapping are frequently still necessary in order to obtain satisfactory surface finish and thread tolerances from the pre drilled hole .

The technologies of Industry 4.0 such as sensors, data analytics, and machine learning are progressively starting to optimise the threading process by means of real-time monitoring and predictive maintenance. These technologies are expected to lower the breakage of tools, maintain the quality consistency and contribute to minimization of the disruptions in production pre drilled hole.

Conclusion

Threaded hole is a very crucial point between design and production where all vital attention should be paid to materials, processes, applications and even circular hole threaded rods, especially during drilling operation . The clear definition of the difference between tapping and threading and the appropriate selection of tools and process parameters allow the manufacturers to make perfect threaded holes in a secure and repetitious manner.

The decision on which type of threading to use between tapping and the other forms of threading is done depending on the particular application demands such as the material to be used, volume of productions, quality demands, and cost related factors circular holecorrect size. With the new materials and technologies that have come to define the continual refinement of manufacturing practices today, basic tenets relating to the creation of threaded holes with an appropriate depth and an understanding of techniques such as half turn is still a skill that engineers and manufactures should know.