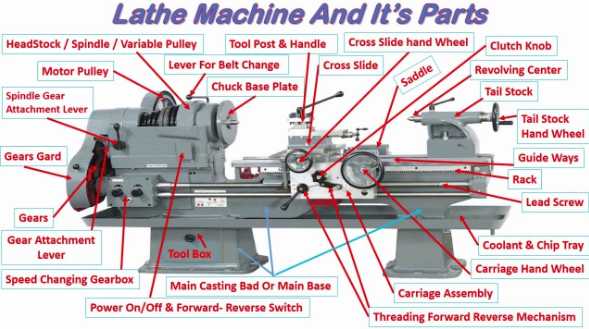

CNC (Computer Numerical Control) cnc lathe machines are the finest form of precision machining technology which turn raw materials into accurately designed components which serve the related industries around the globe. It is important that operators, engineers and manufacturers of such complex machines understand the various machine parts forming these advanced machines and require maximum performance and reliability of the machine during its work in the machining process.

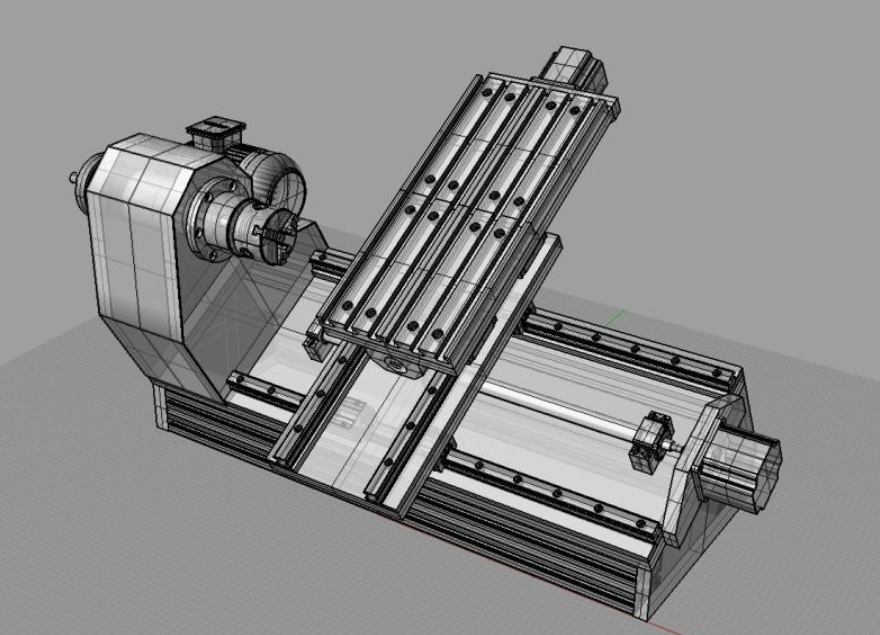

What is a CNC Lathe Machine?

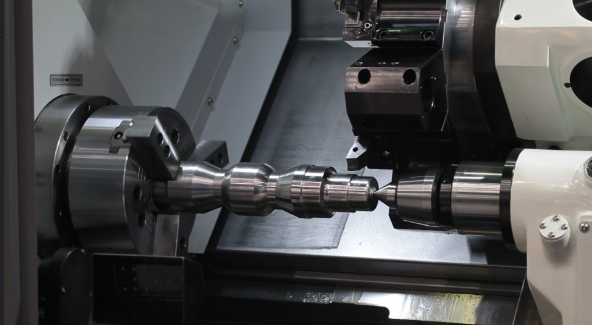

Computer numerically controlled CNC lathe is a completely computer-aided machine tool turning and drilling machines with computer turned programming to achieve a high degree of precision. CNC lathes are unlike the manual lathes, where the use of G-code programs results in high accuracy and repeatability in performing complex machining services. The CNC lathe has motorisation in all its axis of motion including its multi-tool post (capstan). The operations are mechanized, under the control of a program which reads G-code and thus the production can be fully repeatable, with the operator being hands-off.

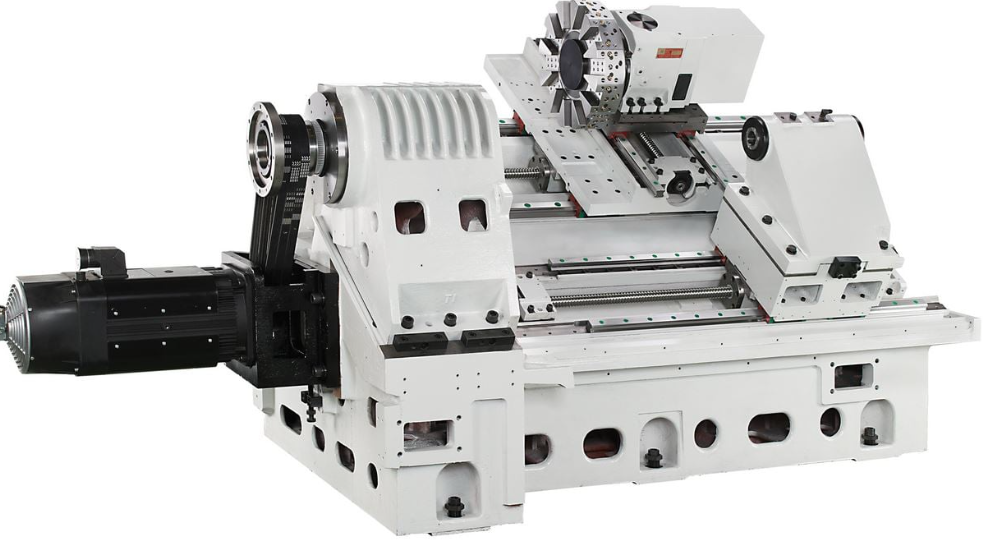

The Heart of Precision: CNC Lathe Headstock

A headstock is one of the critical lathe components and the engine to any lathe machine parts CNC lathe machine. This is where the important part holds the main spindle, motor assembly and gear mechanisms that give the rotational force needed in machining process. The headstock establishes the swing of the machine or in other words the maximum possible diameter of workpiece fit into it.

Key Functions of the Headstock

The main role of headstock is to support and rotate the non-ferrous piece through keeping it centered absolutely concentrically during the cutting process . The spindle is pushed by the motor with diversified speed ratios so that the operators can choose the desirable cutting tool speeds of dissimilar materials and applications. The high-quality headstocks include precision bearings that can take several directions of major forces sustained in machining precision cutting.

Headstock Maintenance Consideration

The headstock bearing should be regularly maintained with proper maintenance since they support heavy loads to ensure a smooth operation when a machining operation is in progress. The effect of vibration and overloads may possibly reach motor stall limits and hence bearing condition monitoring is an important service requirement especially in machinery that are highly used.

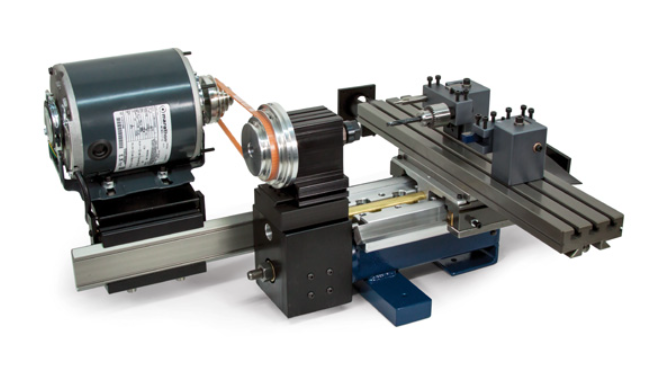

Foundation of Stability: CNC Lathe Bed

The lathe bed is the structural basis of the metal lathe machine forming the brand chassis on which all the working parts rest. This strong beam is the entire length of the machine and must be of high rigidity not to deform even within the extreme operating conditions precise cutting.

Materials and Construction

Even more advanced materials have been used in the modern milling machines CNC lathe beds, based on vibration dampening capabilities as well as strength. The typical materials involve cast iron, mild steel, ductile cast iron and the high tech composite materials such as Granitan. Granitarian or other materials have little risk of cracking and chipping, better toughness and high vibration damping various machining operations.

Vibration Damping Properties

Excellent lathe beds simply have high natural hysteretic effects, and absorb vibrational energy. This feature is measurable in that it is possible to test it by hitting a material with a hammer and dull thud is a good sign of damping quality in lathe operation machining operations, and a high-pitch ring is a bad one that says you do not control vibration well.

Precision Workholding: Chuck Systems

The chuck is a possibly most important part of workpiece security and precision, as it ensures the cutting tool’s position is correct . The workpiece is clamped at the center of rotation by this device and allows effective loading and unloading metalworking lathes.

Three-Jaw Universal Chucks

Three-jaw chucks possess self-centring ability with stepped jaws that have the possibility to suit different diameters of workpieces, accommodating multiple cutting tools . Either end has stepped settings to handle larger pieces of material, at the other is a beveled end that grasps smaller diameter material-exactingly.

Four-Jaw Independent Chucks

The adjustment is independent on each jaw of a 4-jaw chuck allowing precise centering and fitment of square or mis-shaped work pieces. They take more time to set up, but are much more versatile, when it comes to working with non-cylindrical parts unparalleled precision.

Specialized Chuck Types

Finer applications Compound applications employ magnetic chucks of ferrous material too fine to be gripped mechanically, drill chucks collet chucks of precise-tool-holding capability, and combination chucks, which cut down tooling variety in use, but have a more complex operating cycle in cnc machining conventional lathes.

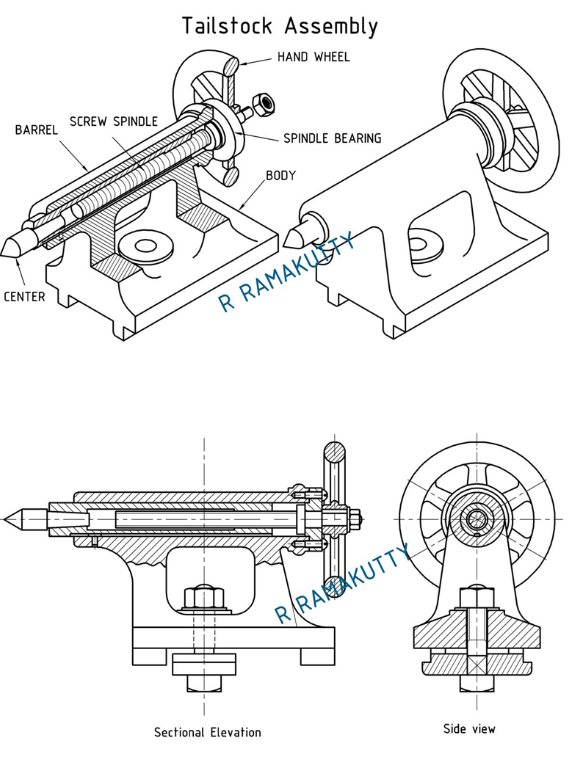

Support and Precision: Tailstock Assembly

The tailstock is necessary when supporting workpieces and has various operative roles. It is situated directly opposite the head stock, on the same rotational axis and so can hold the free end of a rotating workpiece or the drilling tools in a center-axis machine precision metalworking.

Tailstock Functions

Typical uses of tailstocks are; centering tools to support parallel/price long operations, drill chucks to drill small-diameter holes, and hold Morse taper type drill bits to drill directly into the center for precision turning operations .

Adjustability and Positioning

The tailstock construction has the ability of longitudinal positioning along the bed ways and its clamping mechanism is foolproof to hold its position during machining irregularly shaped workpieces. Such flexibility makes it easy to support the parts of cnc lathe workpiece in a proper way irrespective of component length.

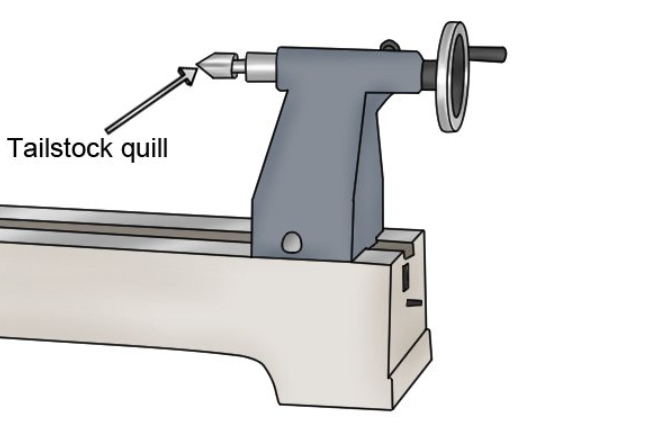

Precision Movement: Tailstock Quill

The quill is what can move of the tailstock assembly, and includes a cylindrical base wherein Morse taper tooling can be set precise control. This part gives regulated progress towards the work-part drilling and center-stabilization purposes.

Quill Operation

The quill mechanism gives good control over feeding to the drilling operations and keeps a concentricity with the spindle axis, which is vital for maintaining precision in cnc turning machines. Good ones have graduated marks on depth control and ease of movement which is necessary in precision work.

Operator Interface: Control Systems

Contemporary CNC lathes include advanced control console that both controls lathe processes and program execution desired shape. Such systems are usually made up of independent machine and control panels, which carry out different purposes.

Machine Panel Functions

The machine panel allows the machine operators to set the characteristics of operation, control axes of cutting tools, jog machine axes manually to configure and position the machine. The controls, including various electrical components, give direct access to machine manipulation that is necessary to setup and also to trouble shoot cross slide.

Control Panel Programming

The control panel enables the entry, editing and memory management of the programs. Pallet-mounted displays indicate a G-code programming, and operators can either enter new programs or change existing sequences tool holder. This interface is the main medium of communication between the intention of the operator and the action on the machine.

Operational Convenience: Foot Controls

Foot switches and electrical components pedals allow the operator to operate vital functions of the machine without using the hands when handling the workpieces or tools. These controls have the ability to operate the chuck open and close in the case of hydraulic or pneumatic machines, tailstock automatic set up and emergency stops to control safety.

Safety Integration

Emergency stop foot pedals allow shutting down the machine directly when the operators notice some dangerous situations or programming mistakes lead screw. This emergency means that they are quickly responsive in case one is busy operating the machine during machining tasks cnc lathe machine work.

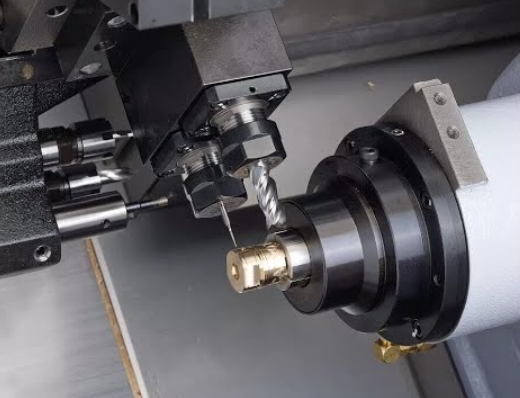

Automated Tool Management: Tool Turret Systems

The business end of CNC lathe operations is the tool turret in which there are various cutting tools ready in accurately indexed positions. All the positions of the tools are precisely measured and recorded in the memory of the machine to automatically select and position the tools.

Tool Selection Automation

The difference between CNC system and a manual turret lathe is that in a manual turret lathe the tools are manually rotated into the cutting position, in a system like CNC this is done automatically according to program instructions. This is an automation, which reduces constant removal of tools, and creates a repeatable tool location through the production of parts parts of a cnc.

Tool Turret Precision

The current tool turrets have a fine indexing mechanism which locates tools in fine tolerances. Surface finish and part quality are directly related to the accuracy of positioning of the tools, and one of the most decisive points of performance of the parts of a cnc machine is its turret precision.

Power and Motion: Spindle Systems

The spindle is an essential part of CNC turning center and supplies the necessary rotational force either on the lathe tools work piece or the cutting edge cnc lathe machine parts. The spindle system consists of main shaft, bearings and some drive types that enable machining to operate with a controlled rotation.

Spindle Drive Systems

Most cnc lathes have variable frequency drives and synchronous motors to give accurate control of the speed. The spindle speed also directly influences the cutting conditions, the finishing of surfaces, and tools life so that the proper controlling of this parameter is the key to the maximum positive results of machining.

Bearing Systems

Spindle bearings are required to demonstrate radial and axial loads force and precision upon different speeds. The demand of good machining conditions will be handled by a good quality of angular contact bearing or optimum spindle bearing with which the bearing will roll easily and have a long service life.

Motion Control: Feed Systems

Feed systems regulate the movement of cutting device with respect to the work piece which provides accurate material removal rate and finishing. Such systems come with servo motors, ball screws and linear guides that can give exact positioning.

Servo Motor Technology

In the modern cutter control and numerical control lathes, servo motors and encoder feedback control position. The systems offer a high degree of accuracy and repeatability to the cnc control panel tight tolerance machining needs.

Ball Screw Mechanisms

Ball screw assemblies, convert rotational energy into similar motion, and provide a small backlash. These assemblies are high efficiency and durable. The precision parts allow the easy movement and accurate placement of the tool all through machining envelope.

Accuracy Feedback: Measuring Systems

Modern CNC lathes have advanced measuring tools that determines the position of the machine and feedbacks on accuracy. Such systems are the linear scales, rotary encoders, and probe systems.

Linear Scale Technology

Linear scales also offer instant position feedback with no reliance to mechanical drive systems, thus automatically discarding accumulating errors, and introduce superb accuracy. Such systems are playing off thermal expansion or mechanical wear.

Rotary Encoder Systems

Spindle position and speed is monitored by rotary encoders and allow thread cutting, rigid tapping and angular positioning. High resolutions encoders supply the precision required during complicated machining tasks.

Structural Components: Ways and Guides

Machine ways and the linear guides offer an accurate direction of motion to moving parts and remain accurate under a load. These systems need to be wear resistant and smooth and correct in their motion through out the service life of the machine.

Way Design Variations

The conventional box ways have excellent rigidity and damping properties, and linear guide systems offer low friction and better precision. Literature values are based on requirements and application philosophy of machine design.

Lubrication Systems

Timely ways and guides lubrication will guarantee a user-friendly service life. Automatic lubrication systems release oil or grease to critical wear locations keeping the machine or machine component under optimum operating conditions.

Cooling and Chip Management: Auxiliary Systems

Good coolant systems, chip management systems and cutting conditions must be maintained so that various machine parts are not contaminated. Such systems consist of pumps, filtration and chip owing systems.

Coolant Distribution

Programmable coolants systems pump the cutting fluid to precise machining areas and extends tool life and surface finish and controls heat generation. The right selection and maintenance of the coolant are necessary.

Chip Removal Systems

Automated chip clearing is used to ensure no pile up is formed which may disrupt the accuracy of machining or destroy machine parts. Swarf is removed by chip conveyors and auger systems out of the cutting field.

Safety Systems and Interlocks

The tubular lathes in the present day have advanced safety systems, which safeguard people and machineries. Such systems contain guards, interlocks, and emergency stop devices which make their operations safe.

Guard Systems

The safety guards are such that would ensure the operator does not have contact with the moving parts and the machining is visible. Interlocked guards prevent operation of machine when opened and they would not accidentally come in contact with hazardous parts.

Emergency Stop Systems

Emergency stop push buttons and systems are an instant shut down option for a machine in the event a dangerous condition occurred. Such systems are positioned, where they can easily be accessed by the operators in emergency cases.

Electrical and Control Infrastructure

All the machine functions are powered and managed by the electrical system that brings about power distribution in the machine. This infrastructure comprises motor drives, control processors and communication networks and their interconnected status manages the functions of a machine.

Drive Technology

Output of variables speed and variable torque of motors are governed by variable frequency drives, which also feed back on positioning. The systems also allow accurate positioning of motions needed to perform precise machining.

Communication Networks

The industrial communication protocol applied in modern machines connects controllers, drives and other peripheral equipment. Such networks facilitate coordination of performance and diagnosis across whole machine system.

Workholding Accessories and Fixtures

Machine accessible workholding accessories provide special applications. These are spiral fixtures, steady rests and follow rests which hold work pieces that are tough in shape.

Custom Fixture Design

Fixtures Application-specific fixture can efficiently create complex parts and be very accurate and repeatable. Correct fixture design saves time in set up and better part quality.

Support Systems

Non-deflection support As long or flexible workpieces can deflect, steady rests and follow rests help support workpieces and avoid inaccuracy or poor surface finish.

Maintenance and Service Access

During machine design, there should be provision of regular maintenance and service needs. Maintenance is efficient and is easily achievable through accessible service points, diagnostics systems and design of the components, which are modular.

Preventive Maintenance Programs

Maintenance schedules are done to provide optimum service of the machines and its long life. These programs deal with the process of lubricating, alignment and replacement of components as per the hours and circumstances of operation.

Diagnostic Capabilities

Diagnostic systems installed on the devices can observe the state of the machines and warn the operators of the impending malfunctions well in advance. The systems lower unexpected downtimes and expenses of maintenance.

Advanced Features and Options

The contemporary CNC lathes come with superior functionalities to improve both capability and productivity. These are live tooling, sub-spindles and bar feeding systems which facilitate complex operations and lights-out manufacturing.

Live Tooling Systems

Live tooling Northeastern 2009 allows milling operation on turned parts but minimizes the set up time and achieves higher precision by finishing the parts in one chucking only. Such systems also have increased power and control demands.

Sub-Spindle Operations

Sub-spindles can be used to transfer workpieces and therefore produce finished parts fully. The ability lessens handling and enhances high-rate-of-production pursuits.

Quality Assurance Integration

In process measurement systems allow real time quality and process correction. Such systems provide touch probes, laser measures and vision systems to check for dimensions of the parts being machined.

Probe Systems

Touch probe systems allow measurement of part dimensions as well as tool wear, and allow automatic offset compensation and process optimization. These systems enhance quality of parts and cut the scrap rates.

Vision Systems

Optical measurement systems furnish dimension verification in non-contact application and surface quality gauge. Such systems allow 100 percent inspection power in important applications.

Environmental Considerations

The environmental concern is being alleviated in modern machine design by reducing energy usage, minimizing the wastes generated, and the use of environmental-friendly manufacturing processes. These have implications on coolant systems, power consumption, and material consumption.

Energy Efficiency

Active motor technology and variable speed drives use less power with unreduced performance. These systems are both beneficial to the environment and are cost effective.

Waste Management

Online monitoring and control of chips and coolants eliminate and reduce wastes and allow recycling of chip and cutting fluids. Such systems facilitate sustainable production activities.

Future Technology Trends

Future technology still expands CNC lathe possibilities in the form of artificial intelligence, IoT connection, and material. These advancements hold the potential of a higher productivity and capacity.

Artificial Intelligence Integration

AI can be used to optimise cutting parameters, repair costs and efficiency of the process. The technologies make it possible to act independently and in improving ways.

IoT Connectivity

The Internet of Things can be remotely checking, predictive maintenance by having the potential to monitor the fleet. These systems give useful operational measures and increase the use of equipment.

Conclusion

Knowledge of the machine parts and their functions of CNC lathe can help to maximize the performance of the machine, guarantee the safety of the operator on the machine and ensure best production outputs. All the parts serve an important role in the whole product, such as the strong headstock that is used to power the cnc turning of work pieces as well as the advanced control systems taking complex programs and performing with accuracy modern lathes.

Combination of these elements constitutes a manufacturing system that is able to develop parts of high precision and repeatability. The following are the key or most important lathe CNC machining components compound rest; Headstock, CNC lathe bed, chuck, tailstock, tailstock quill, CNC control panel, tool turret, spindle system, and feedback systems. The knowledge of how to use and maintain these systems steers their performance in a reliable manner and have a long service life.

Contemporary CNC Lathes are still evolving and new improved technologies have made the use so capable and easier to use. Some of these advanced machines offer flexibility and accuracy required in production of challenging demands in various machine tools as the manufacturing demands are becoming very complex.