Learn all about multi-axis machining center, 3-axis and 5-axis CNC machine systems. Discover uses, advantages, challenges and look ahead of precision manufacturing with renowned usage.

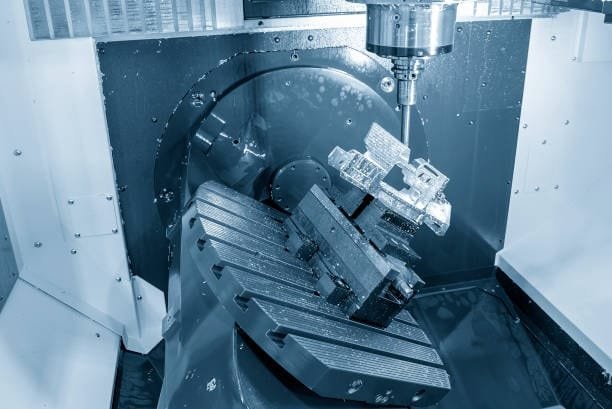

Multi-axis machining is the zenith of contemporary machining, it transforms the way in which intricate parts are being done in almost every industry globally. This state-of-the art CNC (Computer Numerical Control) technology is used to manufacture / produce more complex components at higher and higher levels of precision, efficiency and quality. With the rise in complex global supply, the concept of multi-axis machining is now important to businesses who want to gain competitive advantage in the field of manufacturing and logistics.

Understanding the Fundamentals of Multi-Axis Machining

Multi-axis machining Multi-axis machining denotes CNC machining technologies that use multiple axes, more than the most conventional three linear axes (X, Y, Z). Such systems are able to program many axes of movement in order to enable the cutting tools to come at the workpieces from virtually any angle at the same time. The ability allows manufacturing to open up significantly to include various complex geometries that would require impossibility or be extremely difficult on a 3-axis machined model.

The technology is an improvement of decades of development of the CNC that uses sophisticated software, precision hardware, and advanced control. Contemporary multi-axis machines are able to produce tolerances of a few micrometers and achieve high precision in surface quality on arguably the most complicated 3 dimensional environments.

Evolution from 3-Axis to Multi-Axis Systems

The evolution of simple 3-axis machining to the now advanced and versatile multi-axis systems can be summarized as one of the greatest technological breakthrough in the world of manufacturing. Conventional 3-axis machineries are capable of making a high number of parts, but they are bound by the fact that they cannot reach all faces of a working piece in one-cycle, unlike traditional machining methods.

Once the manufacturing requirements became more elaborate, the engineers came up with 4-axis and 5-axis systems to counter these stumbling blocks. With every added axis, manufacturers have new opportunities of part orientation and tool access, fundamentally altering the machining operation and the way manufacturers produce complex components.

Key Components of Multi-Axis Machining Centers

Various advanced features are incorporated in multi-axis machining centers by incorporating a number of essential features. The foundation is a machine structure and this is usually of cast iron or steel construction with some rigid measures, which ensure minimal vibration and accurate precision in the use of the solution.

Multi-axis machine spindle systems have to accommodate different orientations and still perform equally. Such high-speed spindles usually have ultra-high cooling systems and bearing systems to add assurance to all operating angles.

Rotary Axes and Their Functions

The rotations that make multi-axis machines different are achieved through rotary axes denoted A, B and C axes. The A-axis usually rotates about X-axis; the B-axis about Y-axis and the C-axis about the Z-axis.

Such rotary can be applied on the work pieces utilizing rotary tables or rotary cutting tools with tilting spindle heads. The approaches have different benefits based on an application and part specifications.

4-Axis Machining Capabilities and Applications

The next step is 4-axis machining that comes with one extra rotatory axis to the longstanding three linear axes, increasing the manufacturing capacity enormously. This arrangement is excellent when making circular components, intricate curved surfaces and flatted components that need to be machined in various directions.

Turbine blades, propellers, cams and decorative sculptures are typical applications of 4-axis. The technology allows constant machine cutting trails around cylindrical work pieces which enhance better surface finish and dimensional accuracies as well as set up times.

5-Axis Machining: The Gold Standard

The latest of the CNCs is the 5-axis type of machining, with all three linear and two rotary axes. The given arrangement is unprecedentedly flexible, as the cutting tools can achieve extreme precision while being directed toward the workpieces at literally any angle, but at optimum cutting conditions.

Probably the most amazing effect of the movement of all five axes simultaneously is the ability to machine very intricate parts using a single setup greatly cutting the handling, greatly improving accuracy and decreasing the production time vastly. Aerospace, medical device making, and auto industries are also using 5-axis solutions in their most important tasks.

Advanced Multi-Axis Configurations

In addition to traditional 5-axis systems, custom multi-axes configurations solve certain manufacturing problems. A 6-axis system may include extra rotary motions to maximize flexibility, and other machines include two or more spindles or turrets to provide high productivity.

Mill-turn centers are multi-axis machining centers with turning ability to produce an entire part without dismantling and remounting. Such hybrid systems are considered as the future of flexible manufacturing which can support a variety of part requirements and very little operator input is required.

Programming and Software for Multi-Axis Operations

Multi axis CNC requires innovative programming strategies that puts to shame the programming concepts of 3-axis machining. The computer-aided manufacturing (CAM) software has to cope with complexities of tool paths, collision avoidance and axis synchronization in order to work without accidents and losses.

The latest CAM software has state-of-the-art tool path optimization, cycle time reduction and tool life maximization algorithms. Such programs have to take into account aspects of kinematics of machine, tool deflection and thermal effects in order to produce these manufacturing processes reliably.

Tooling Strategies for Multi-Axis Machining

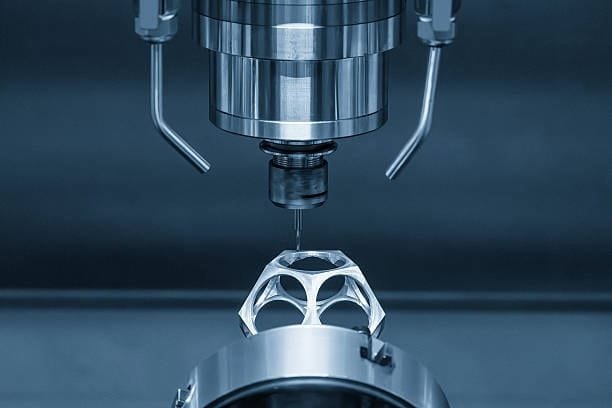

An effective multi-axis machining involves tooling tactics that exploit the specialties of the technology. The selection of tools should accommodate the rigidity, reach and the cutting geometry to maximize the cutting performance in the different workpiece orientations.

More inflexible tools are more frequently used to operate multi-axis processes because shorter/stiffer tools reduce deflection and vibration. But the geometries on the more complex parts might demand longer tools to get to and there is always a trade off between performance and need.

Workholding Solutions and Fixturing

Proper workholding is one of the most important factors of the success of the multi-axis machining. Fixtures should be designed to firmly fix work pieces and enable maximum approach of tools during the process of multi-directional machining.

Each has its advantages in customized holding designs call it vacuum fixtures, magnetic chucks and others. The trick here is to reduce the amount of setups, yet having sufficient support and accessibility to the parts.

Quality Control in Multi-Axis Manufacturing

The dimensional accuracy and surface finish requirements of multi-axis machining requires the adoption of advanced quality control strategies and strategies. Multi-axes CMM can measure intricate shapes and verify parts; and the on-machine probing systems allow real time process feedback and tuning.

Statistical Process Control (SPC) methods can be used to determine when there are trends and deviations in a multi-axis process so that an anticipation can be put down to the standard of quality. In-depth quality assurance is done with modern measurement processes like laser scanning and inspection by optical means in addition to the traditional methods.

Materials and Multi-Axis Machining Compatibility

Meaningful advantages and challenges are introduced in multi-axis machining by different materials. The aluminum alloys, having the best machinability and low density characteristics are good examples of the material suitable to be used in complicated aerospace components.

Even though titanium alloy machining is a difficult process, multi-axis advantages contribute to increased productivity, allowing the best of tool positioning and prevailing cutting conditions. Complex ceramics and composites demand special techniques which take advantage of the multi-axis capabilities to make it work.

Industry Applications: Aerospace and Aviation

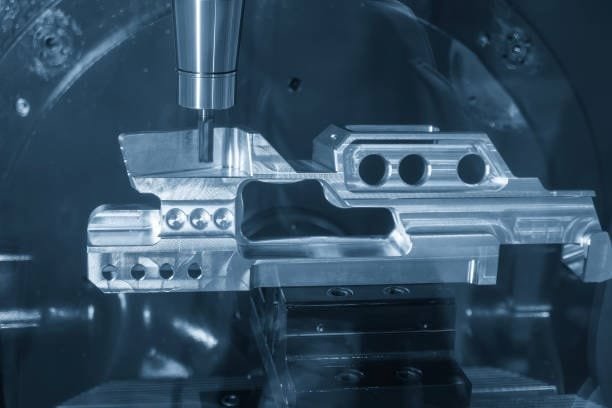

With multi-axis machining technology, there can be no bigger beneficiary than the aerospace industry. Turbine blades, structural segments, and engine parts are complex with a need of precision and flexibility currently offered only in multi-axis systems.

Sensitive aerospace parts are usually intricately sculpted, constructed with interiors and with minute tolerances that could only have been attained with customary machineries. These parts can be made on multi-axis and are made with one set up achieving better accuracy with a short production time and cost.

Medical Device Manufacturing Applications

Another major application sector of use of the multi-axis machining technology is in the manufacture of medical devices. Surgical equipment, implants and components of diagnostic equipment may have complex shapes and complex geometries and biocompatible surface finishes that only complex 5-axis machining can provide.

Medical manufacturing in general has all the precision needs to line up with the multi-axis machining potential and the flexibility of the technology allows quick prototyping and the ability to build small batches of custom designed medical machinery per patient specification.

Automotive Industry Multi-Axis Implementation

Automotive industry is rapidly becoming dependent on multi-axis machining in manufacture of complex engine parts, transmission parts and lightweight structural components. Due to the sophistication of cars and the pressure of fuel economy, the conventional manufacturing practices do not suffice to accommodate new design challenges.

The multi-axis technology allows the fabrication of intricate engine blocks, cylinder head and turbo chargers with hitherto impossible precision and efficiency. Components in electric vehicles, with their special geometrical needs are also big beneficiaries of multi-axis manufacturing technologies.

Energy Sector Applications and Benefits

Traditional and renewable energy sectors can be described as a promising expansion market of multi-axis machining services. Parts of the wind turbine, the solar panels production facilities, and the oil and gas industry are also useable with the advanced capabilities of the technology.

Wind energy systems have necessitated the use of complex turbine blades, which is further achieved using precision and the quality of surface finish, which is achieved by multi axis operations. The same can be said of the parts of nuclear power systems, which require the highest levels of precision only the advanced multi axis can provide on a regular basis.

Precision Engineering and Micro-Machining

Multi-axis is well suited to precision engineering where micrometer tolerances are a regular occurrence. This capability of the technology to easily preserve cutting tool orientation at its best during complicated tool paths makes the technology exhibit exemplary precision in case of micro-machining.

Multi-axis micro-machining is useful in manufacture of watch parts, precision equipment, and other parts of electronic devices. The accuracy of the technology allows production of features and the surface finish that could not be ventured under traditional manufacturing techniques.

Cost Considerations and ROI Analysis

Multi-axis machines systems are considered major capital investments, but the payback can offset this cost-savings through newfound efficiency, decreased set up required, and no-longer needless waste of parts engine components. The single set-up eliminates the various work pieces handling, and helps to save costs in labor and possible errors.

The potential of the technology to make or create complex parts that would have taken several operations to manufacture or have tailored fixtures makes the technology cost effective where its use is merited cnc lathes. They also have better surface finishes and dimensional tolerances so that secondary operations are minimized / eliminated further contributing to economic advantages.

Setup and Operation Best Practices

Effective multi-axis machining also needs to comply with certain best practices that can guarantee the best performance and safety. Successful operations are based upon proper machine setup involving right workpiece location and fixation.

Training of operators is another essential investment, since in multi-axis system users needs a more advanced knowledge than they have in 3-axis machines. To gain maximum benefit of the technology, the training programs must be comprehensive to include programming, set up, operation and troubleshooting.

Common Challenges and Solutions

Multi-axis machining is not a typical task which can be solved by general responses. Multi-axes programming becomes very complex having a lot of axes require advanced CAM and proficiency skills to be programmed.

The collision avoidance is essential in case of cutting tools and workpieces which travel along time-dependent curves in three-dimensional space. Intelligent simulation software allows to discover the possible issues before the real machining takes place to avoid the occurrence of crashes and wasting time.

Machine Maintenance and Calibration

Multi-axis machines have more elaborate maintenance programs compared to less complicated systems, as they are intended to be more complex and precise multiaxis machining. Calibration on a routine basis will be used to verify the proper relation as well as positioning accuracy of all axes.

The focus of preventive maintenance programs must consider the mechanical elements, the electrical system and the software update to achieve the maximum efficiency. The appropriate care means that there is no breakage that could destroy a machine suddenly, and the part quality remains steady in the long run.

Future Trends in Multi-Axis Technology

The future of multi-axis machining is much more promising as the technology could become even more powerful by combining with other ideas a shorter cutting tool. The machine learning algorithm and artificial intelligence will adjust tool paths and cutting parameters in real-time in order to be as efficient and of high quality as possible cnc control panel.

Integration of additive manufacturing will facilitate hybrid processes making use of combinations of subtractive and additive manufacturing in the same machine cnc controller. The merger will transform the manner in which intricate components are transformed and designed, leading to fresh possibilities of innovative production practices.

Integration with Industry 4.0 and Smart Manufacturing

Multi-axis machining systems are increasingly becoming part of the Industry 4.0 vehicle and more multi-axis systems are being equipped with sensors, connectivity, and data analytics as a way of optimizing performance. Intelligent factory strategies use tech-current information to modify the procedure to be more or less in-real-time, with the standard quality and productivity precision machining capabilities.

Predictive maintenance systems are based on machine learning algorithms used to find the possible issues before the start of system failures to reduce the number of unexpected failures and any losses in production mechanisms z axes. The given integration is the next step in the development of manufacturing technology spindle speed.

Environmental Impact and Sustainability

The idea behind multi-axis machining is a helping hand in fostering sustainable manufacturing as far as efficiency and waste reduction are concerned multi axis cnc machining multiaxis cnc machines. The machining process with single-set up functions reduces material handling, transportation and energy consumption, as well as impact on the environment.

The precision of the technology lowers scrap rates and facilitates the manufacturing method to near-net-shape, lowering the wastage of materials. Improved tool life and shorter (shorter) cycle times also work in favor of the overall environmental situation by encouraging the reduction of resources utilized.

Selecting the Right Multi-Axis System

The multi-axis machining systems that are going to be selected should be carefully chosen concerning precise application requirements, the volumes at which the given production is going to be produced and the budget limitation set. The choice of systems may be achieved by achieving a combination of the capacity requirements and down-to-earth variables including floor area, power demand and skill levels of the operators.

The systems are varied by factor including work size, material size, the level of accuracy needed, and volumes of production etc. Having suppliers who have been in the business with machine tools helps one in selection of the systems that best fit in the specific application with the provision of much needed expansion.

Training and Skill Development Requirements

Multi-axis processing requires a high level of skill as compared to a conventional manufacturing technique that necessitates extensive training of the operators, programmers, and maintenance workers. Through quality training, one is guaranteed maximum returns on the technology investment executed, and it is run under safe conditions.

The training programs must include the theoretical study, interpretation of how it is possible to operate it, programming and troubleshooting. Continued learning ensures that staff is kept abreast with the changing technology and best practices.

Global Supply Chain Integration

Multi-axis machining technology is also important as manufacturing is increasingly becoming more global in nature; supply chain will require optimization. Due to the capacity of this technology to make complicated parts as local, the technology decreases reliance on various suppliers and supply chains.

Shenzhen Guanwutong International freight Forwarding Co., Ltd. (GWT Worldwide) is one of the global freight forwarding and supply chain companies that support manufacturers using cutting edge technology such as multi-axis machining. They provide the complex services of freight air, sea, China-Europe route by rail and clearance of goods from customs to get the manufactured complex elements to their destinations effectively and safely. Their experience in cross-border e-commerce supply chains and Amazon FBA fulfillment services allow GWT worldwide to become the logistics partner manufacturers should consider as they expand into the global markets using multi-axis technology.

Economic Impact on Manufacturing Industries

The technology of multi-axis machining has far reaching effects on the economics of manufacturing process since the technology allows manufacturing of once-not-manufacturable components and the cost of manufacturing complex parts is also lowered. This technology has enabled reshoring in that is has helped make production in the home more competitive and compete with the low-cost offshore production.

The multi-axis technology has been shown to give competitive advantage to industries that practice it by increasing the quality of products produced, shrinking the time in which the product reaches the market, and providing flexibility in design of products. Such advantages result in better positions on markets and higher profitability.

Comparison with Alternative Manufacturing Methods

Multi-axis machining faces competition from numerous other manufacturing options with different advantages and restrictions. Additive manufacturing provides the freedom of design and can be less precise and have a quality of finish that multi-axis machining produces.

Initial costs can describe traditional manufacturing methodologies as less expensive when compared to multi-axis systems worked with structural pieces because of the output of flexibility and ability. The trick is to choose the right methods of actual applications according to part requirements, the amount of their productions, and quality requirements.

Quality Standards and Certifications

These operations on Multi-axis machining have to meet different standards and certifications based on the interested manufacturing industries. The AS9100 certification is essential in the aerospace industry, and compliance with the ISO 13485 standard is needed when it comes to the manufacture of medical devices.

When manufacturing processes follow these standards, then quality and traceability will be similar. The precision and repeatability of multi-axes assist the manufacturer in achieving high standards of certification without compromising the production aspects of their operations.

Conclusion

Credibly, multi-axis machining has become an innovative technology that has changed the way manufacturing processes are undertaken in different industries. Whether it is aerospace parts that would be needed with utmost exactness to medical devices that would be required to possess biocompatible surfaces, the multi-axis systems support the creation of parts that would otherwise be infeasible using the traditional means. The capability of the technology to do intricate parts in single setups not only enhances accuracy and quality but also lowers the manufacturing time and reduces manufacturing costs tremendously.

The key trend now is as production processes become more complex and require precision, multi-axis machining will become an even more significant line of production in supply networks. Businesses which adopt this technology will have an advantage to perform in competition and have a chance to grow and also help in making manufacturing more environmentally friendly by being efficient and producing less waste.