In production, the aircraft sector is most demanding for dependability, durability, and accuracy. Producing parts for aircraft, spacecraft, and defense systems depends on machining since it guarantees they satisfy high safety and performance criteria. Modern technologies and advanced machining methods let producers produce incredibly exact, lightweight, high-strength products. The value of machining in the machining aerospace parts, the materials utilized, modern machining techniques, quality control procedures, and industry future trends is investigated in this paper.

What is CNC Machining?

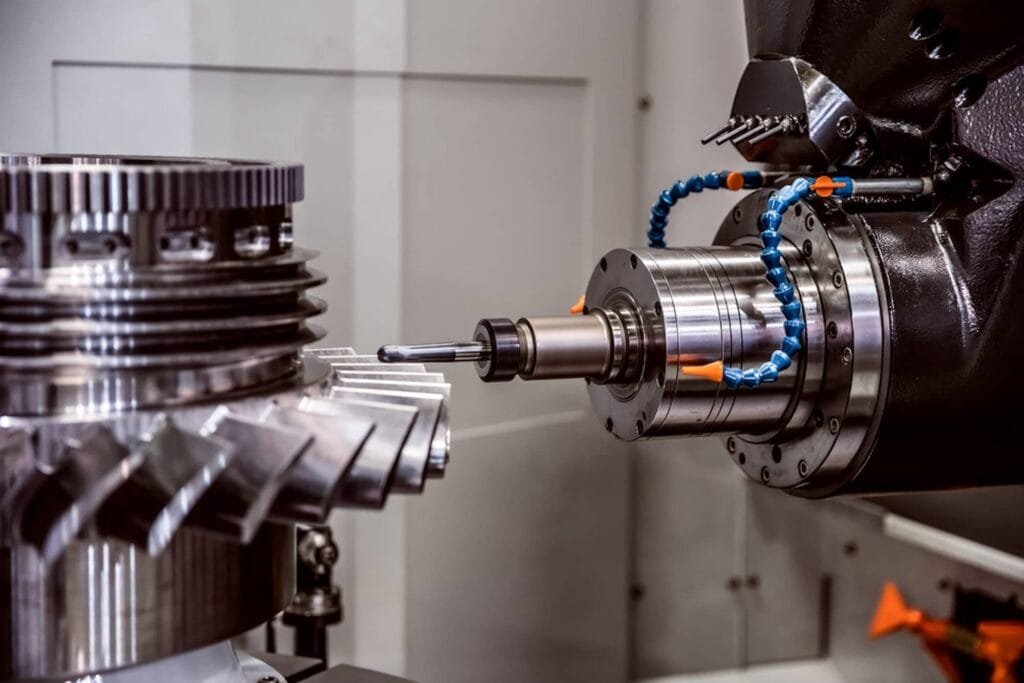

Using computer-controlled machines to painstakingly cut, shape, and form various materials, including metals such aluminum, steel, and titanium, as well as plastics and even wood, Computer Numerical Control (CNC) machining is an advanced precision manufacturing technique that minimizes human involvement to produce extremely accurate and complex geometries. Broadly speaking, the term “CNC machining” refers to a range of subtractive manufacturing techniques including cutting, milling, turning, drilling, grinding, routing, and polishing, all of which are controlled by pre-programmed instructions guaranteeing an outstanding degree of consistency, accuracy, and repeatability over the production process axis cnc machining.

One of the main benefits of CNC machining is its amazing cost efficiency; the technology greatly lowers waste material, minimizes the likelihood of defects, and streamlines both manual labor requirements and setup times, so providing an ideal solution for both high-volume mass production and smaller-scale, low-volume manufacturing as well as for creating one-off custom components tailored to specific design criteria. Sophisticated multi-axis capabilities, automated tool-changing mechanisms, and advanced degrees of automation—all of which help to maximize production efficiency, improve accuracy, and cut the total time needed to manufacture complex components with tight tolerances—are features of modern CNC milling machines.

Moreover, with the development of small, desktop-sized CNC machines, this sophisticated technology has become more easily available to hobbyists, makers, and DIY enthusiasts, allowing them to engage in small-scale projects with a degree of precision that was once exclusive to industrial manufacturing environments, so broadening the reach and uses of CNC machining outside conventional large-scale production facilities.

The Importance of Machining in Aerospace

Production of basic components like turbine blades, engine mounts, landing gear, and structural airframe sections depends on aerospace machining. Aerospace machining, unlike traditional production, depends on exact tolerances—often measured in microns—to guarantee safety and utility. The complexity of aerospace machined parts and aircraft designs calls for highly trained machinists and specific tools.

Direct effects of precision machining are on aircraft performance, fuel economy, and general safety. Precision production and quality control are absolutely vital since a small variation in a precision machined components being good might undermine the whole system.

Materials Used in Aerospace Machining

High-performance materials able to resist mechanical stresses, temperature extremes, and pressure fluctuations define the aircraft industry. Often used components are:

1. Titanium Alloys

Strength-to-weight ratio, corrosion resistance, and heat resistance define titanium as quite valuable. Parts for jet engines, landing gear, and structural components all find application here. But titanium’s heat retention qualities and hardness make it difficult to manufacture.

2. Aluminum Alloys

Airframes and structural parts often feature lightweight, corrosion-resistant aluminum alloys. Their machinability qualifies them as a great alternative for fast milling and drilling.

3. Stainless Steel

For important aircraft components, stainless steel provides great strength and corrosion resistance. It’s found in landing gear assemblies, engine parts, and fasteners most often.

4. Nickel-Based Superalloys

Because they can resist great temperatures and mechanical stress, superalloys like Inconel and Hastelloy find employment in jet engines and exhaust systems. These materials need sophisticated machining methods to keep accuracy and stop tool wear.

5. Composite Materials

Aerospace uses of carbon fiber-reinforced polymers (CFRP) and other composites are growingly common. Although they have outstanding strength-to—-weight ratios, they call for specific machining techniques such ultrasonic machining and laser cutting.

Advanced Machining Techniques in Aerospace

Aerospace machining uses modern technologies to reach required accuracy and efficiency. The most often used aerospace machining companies and techniques consist in:

1. CNC Machining

The backbone of aircraft manufacture is computer numerical control (CNC) machining. Extremely precise aerospace CNC machining machines may generate complicated pieces with little human involvement. These machines generate complex designs by using multi-axis capabilities—3, 4, and 5-axis.

2. Electrical Discharge Machining (EDM)

Machining strong metal and complex forms difficult to cut using conventional techniques is accomplished with EDM. Perfect for turbine blades and fuel injection nozzles, it uses electrical discharges—sparks—to erode material.

3. 5-Axis Machining

5-axis machining helps companies to cut intricate designs with less setups. For aerospace parts like turbine blades and impellers, this lowers machining time and increases accuracy, hence improving their quality.

4. Additive Manufacturing (3D Printing)

Traditional machining is subtractive; additive manufacturing creates layers of parts. Custom brackets and engine components are among the lightweight, high-strength components this method is manufacturing for aircraft use.

5. Ultrasonic Machining

Highly sensitive substances like composites and ceramics are machined ultrasonic-wise. It guarantees exact cutting free from damage to the material and reduces tool wear.

6. Laser and Waterjet Cutting

For metals and composites, laser cutting offers high-precision machining; waterjet cutting is best for heat-sensitive materials. Both techniques guarantee minimally wasted clean cuts.

Quality Control and Precision in Aerospace Machining

Aerospace components have to satisfy rigorous criteria and standards including those established by the International Organization for Standardization (ISO) and the Federal Aviation Agency (FAA). Methods of quality control comprise:

1. Tolerance and Accuracy Checks

Aerospace machining calls for tolerances just a few microns. Accuracy is guaranteed by computerized measuring tools like coordinate measuring machines (CMMs).

2. Non-Destructive Testing (NDT)

Without compromising the part, NDT techniques—X-ray, ultrasonic, magnetic particle testing—help find flaws.

3. Surface Finishing and Coatings

Smooth surfaces are needed for aerospace parts to lower friction and increase lifetime. Techniques improve component performance including shot peening, chemical coating, and anodizing.

4. Automation and AI in Quality Control

Quality assurance and defect identification depend much on artificial intelligence and automation. Machining operations are analyzed by machine learning techniques, which also spot possible mistakes in real time.

Challenges in Aerospace Machining

Aerospace machining presents various difficulties even with technology developments:

- Machining superalloys and composites calls for specific tools and cooling techniques to guard against tool wear and thermal damage.

- Aerospace components are costly to manufacture, hence any delay might greatly affect production plans.

- Strict industry regulations call for constant monitoring and testing, therefore complicating manufacturing techniques.

Future Trends in Aerospace Machining

Machining technologies are developing to satisfy new needs as the aerospace sector is changing. Important trends influencing the future consist in:

1. Automation and Smart Manufacturing

Machining’s integration of IoT, robotics, and artificial intelligence is boosting efficiency and lowering human error. Predictive maintenance helps smart industries improve output.

2. Sustainable Machining

Energy-efficient CNC machines and environmentally friendly machining techniques include dry machining—eliminating coolants—are becoming increasingly common.

3. Hybrid Manufacturing

Faster prototyping and complicated component manufacture made possible by combining additive and subtractive manufacturing

4. Advanced Coatings and Tooling

New cutting tool materials and coatings, notably diamond-like carbon (DLC) coatings, increase tool life and enhance aerospace precision machining and efficiency.

The Future of CNC Machining in the Aerospace Industry

Rapid technology improvements, changing business needs, and growing environmental concerns are driving a major overhaul in the aerospace sector. A new era of aviation is being ushered in by the development of electric and hybrid propulsion systems, the broad acceptance of lightweight composite materials, the integration of autonomous flight technologies, and an emphasis on increased safety and passenger comfort. CNC machining is still a vital tool as these developments change the global aerospace industry scene since it guarantees dependability, accuracy, and efficiency in the production of aircraft parts. Greater automation, improved digital connectivity, the ability to manufacture highly complex components, advanced material processing, modern tooling innovations, seamless integration with additive manufacturing, all while stressing sustainable manufacturing practices will drive CNC machining in this sector.

The Rise of Automation and Digitalization in CNC Machining for Aerospace

The rising importance of automation and digitalization—which are transforming the manufacturing process by improving efficiency, productivity, and quality control—is among the most important developments in CNC machining for the aerospace industry. Real-time data monitoring, predictive maintenance, and adaptive machining operations made possible by the combination of robots, artificial intelligence (AI), and machine learning (ML) algorithms are lowering human involvement while increasing precision and operating costs by means of these reductions.

Furthermore, CNC machining is becoming a natural component of highly linked manufacturing ecosystems where real-time decision-making and production workflow optimization are made possible by seamless digital communication between machines, manufacturing planning systems, supply chains, and quality control units. This degree of connectedness guarantees that aerospace producers may reach ongoing process improvements, lower downtime, and eliminate mistakes, so improving general efficiency and dependability in the production of aerospace components.

The Ability to Manufacture Highly Complex and Specialized Components

CNC machining keeps developing to satisfy the demands of increasingly complicated and specialized components with intricate geometries and strict tolerances demanded in aerospace applications. Advances in multi-axis machining, simultaneous milling, and adaptive machining processes have made it feasible to create very complex objects with outstanding accuracy and surface finishes.

In aerospace engineering, where every detail counts in guaranteeing structural integrity, safety, and performance, the capacity to create intricate components with great accuracy is very vital. Aerospace producers will be able to push the envelope of what is feasible by developing more sophisticated CNC systems with stronger kinematics and real-time adaptive control, so creating components with even more complexity while preserving the highest standards of quality.

The Role of CNC Machining in Processing Advanced Aerospace Materials

Advanced materials are becoming more and more important to the aerospace sector in order to increase fuel economy, lower weight, and boost aircraft performance: To meet these goals, lightweight metals including titanium alloys and carbon fiber composites are being embraced extensively. Because of their hardness, heat resistance, and propensity to produce tool wear, machining these advanced materials brings special difficulties, though.

With better cutting techniques, high-performance tooling, and adaptive machining settings that maximize the machining process for every given material, aerospace CNC machining is always changing to meet these new material needs. Aerospace companies may guarantee exact machining by using cutting technologies, therefore preserving the structural integrity of these high-performance materials.

The Development of Cutting-Edge Tooling and Cutting Technologies

Improvements in tooling and cutting technologies—which are essential for raising machining efficiency, precision, and surface finish quality—are also intimately linked to the development of precision CNC and machining in aerospace. Improved tool life has been greatly prolonged by better tool coatings, sophisticated tool designs, and improved tool materials; cutting speeds have been raised and material waste has been lowered cnc machining aerospace parts.

Aerospace manufacture is increasingly using high-speed machining, multi-axis capabilities, and adaptive cutting techniques to enable shorter manufacturing cycles and more machining complex part precision. Furthermore improving efficiency will be smart tooling systems including sensors for real-time wear detection and automatic adjustments, hence lowering the demand for regular tool replacements and decreasing manufacturing downtime.

The Integration of CNC Machining with 3D Printing in Aerospace Manufacturing

The smooth integration of the CNC machining processes with additive manufacturing technologies, including 3D printing, is another ground-breaking achievement in aircraft manufacture. Although CNC machining is typically needed for post-processing, surface polishing, and the addition of last details to 3D-printed components, 3D printing offers more design freedom and material efficiency.

Aerospace manufacturers can create hybrid components that combine additive and subtractive manufacturing techniques, so leveraging the best of both worlds—creating lightweight, optimal structures with 3D printing while assuring great accuracy and excellent surface quality with precision CNC machining. In the aerospace industry, this hybrid technique is predicted to grow more and more prevalent so that producers may reach hitherto unheard-of degrees of design complexity and efficiency.

The Role of CNC Machining in Sustainable Aerospace Manufacturing

Manufacturers are giving sustainable production techniques top priority as environmental issues define the direction of the aerospace sector and help to lower carbon emissions, cut waste, improve energy efficiency. By maximizing material use, reducing scrap, and using energy-efficient machining techniques, CNC machining is absolutely vital in this effort.

Aerospace manufacturers are cutting resource use using advanced machining processes including near-net form machining—where parts are machined as close to their final shape as possible to avoid material waste—and optimal toolpath generation. Furthermore helping to make CNC machining in aerospace manufacture sustainable are developments in coolant technologies and chip recycling systems.

Conclusion

Aerospace machining is a very specialized discipline needing stringent quality control, superior technology, and accuracy. To create lightweight, robust, high-performance components that satisfy strict safety criteria, the sector depends on creative machining methods. Machining techniques will change to fit new problems as aerospace technology develops, including automation, artificial intelligence, and sustainable practices to propel efficiency and creativity.

CNC machining stays at the core of aircraft manufacture as the aerospace sector develops with innovative technology guarantees the manufacturing of premium, precisely engineered components. Rising automation, improved digital connectivity, the ability to create highly complex components, better material processing, and the acceptance of innovative tooling solutions define CNC machining in aerospace’s future. Moreover, the combination of 3D printing with CNC machining and the move toward sustainable production methods will confirm aerospace cnc machining services and its relevance in the sector even more. CNC machining will be a major driver in determining the direction of aviation as aerospace makers aim for increased economy, better performance, and less environmental impact.