Introduction

Modern car manufacture depends critically on automotive CNC (Computer Numerical Control) machining to guarantee high-precision components improving performance, durability, and safety. The whole automotive precision machining sector has been transformed by this technology, which increases component quality utilized in automobiles, lowers waste, and makes manufacture more effective. We shall investigate what CNC machining is, how it is applied in the automotive sector, the advantages it offers, and its future influence on vehicle manufacture in this blog.

What Is CNC Machining?

Using computerized controls to drive machine tools—such as lathes, mills, and grinders—CNC machining is a manufacturing technique producing precision items from raw materials like metal, plastic, and composites. High accuracy, repeatability, and efficiency made possible by this method make it perfect for automotive uses where accuracy is very vital.

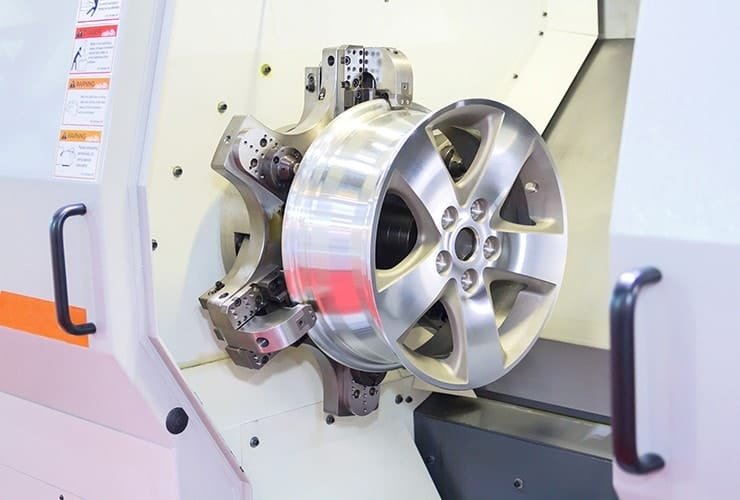

CNC Lathe Machines and Their Applications

For very precise symmetrical pieces, CNC lathe machines are perfect since they rotate a workpiece while a cutting tool molds it. The automotive sector makes great use of these machines to produce cylindrical components from a range of materials, including plastics and metals.

Applications:

Commonly used for manufacturing basic vehicle parts including bearings, axles, and shafts are CNC lathe machines. In automotive production, they are a vital tool since it is possible to create vast numbers of exactly identical parts with little variation.

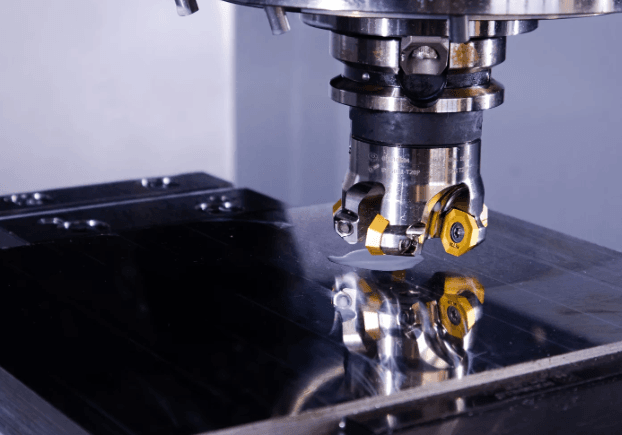

CNC Milling Machines and Their Role in Automotive Manufacturing

Using a spinning cutting tool, CNC milling machines remove material from a workpiece so that manufacturers may precisely shape and refine different vehicle components. These machines can generate more complex shapes, designs and functional components by processing several materials like metal, plastic, and wood.

Applications:

Complex automobile components such engine blocks, transmission cases, and cylinder heads are manufactured using CNC milling somewhat extensively. These components must be precisely machined to guarantee vehicle durability and flawless performance.

CNC Drilling Machines for Automotive Components

Designed to make holes of different diameters in a range of materials—including metals, polymers, and composites—CNC drilling machines Assembling automotive components depends on exact and consistent hole placement, which these machines accomplish using specialized drill bits.

Applications:

The automobile sector uses CNC drilling extensively to create holes in components including engine blocks, gearbox cases, and other structural parts needed for car assembly.

CNC Grinding Machines and Their Significance in Automotive Manufacturing

By eliminating extra material and obtaining a fine surface finish, CNC grinding machines significantly help to improve vehicle components. These machines grind down components using abrasive wheels, therefore guaranteeing that they satisfy high performance and quality criteria.

Applications:

Precision components such gears, pistons, and crankshafts are produced using grinding machines most extensively. To guarantee effective engine performance and long-term dependability, these components have to satisfy certain requirements.

EDM Machines and Their Contribution to Automotive Production

Using electrical discharges, a specialized technique called electrical discharge machining (EDM) shapes and cuts very hard materials such tungsten carbide and hardened steel. This approach enables producers of complex automobile components to create them with amazing accuracy.

Applications:

Making intricate forms needed in moulds and dies used for mass-production of automotive parts depends especially on EDM technology. EDM is a fundamental method in high-precision manufacturing since it allows one to work with hard-to-machine materials.

CNC Waterjet Cutting Machines for Automotive Applications

To cut through various materials with amazing accuracy, CNC waterjet cutting machines run a high-pressure stream of water—sometimes mixed with abrasive compounds. This approach guarantees little heat generation, therefore preventing material distortion during the cutting operation.

Applications:

In automotive manufacture, waterjet cutting is extensively utilized to produce delicate components including car body panels, engine and chassis components,, and other interior panels and fittings as well as complex forms. This process’s great accuracy qualifies for both mass manufacturing and specialized fabrication.

CNC Laser Cutting Machines in Automotive Manufacturing

High-powered laser beams used in CNC laser cutters allow great accuracy in cutting through wood, plastic, and metal. Because it minimizes material waste and generates clean, sharp cuts, this technique is preferred.

Applications:

The automotive sector makes great use of NCNC laser cutting to produce parts including structural elements, brackets, and engine components that call for exact cutting and detailed finishing.

CNC Plasma Cutting Machines for Vehicle Production

High-temperature plasma arc produced by CNC plasma cutting machines allows them to cut through thick materials including metal, steel, and aluminum. In industrial uses, these machines are quite efficient since they are well-known for their fast and exact cutting ability.

Applications:

Fabricating body panels, vehicle frames, and suspension components in the automobile industry makes plasma cutting rather popular. Manufacturing heavy-duty vehicle parts that call for strength and durability benefits especially from this procedure.

Future Trends of CNC Machining in the Automotive Sector

The automobile sector is always changing, and fast growing production technologies are meeting fresh needs of automotive market. Leading among these developments is CNC machining, where new trends will shape car manufacture going forward.

Hybrid Manufacturing: Combining Additive and Subtractive Techniques

Integration of hybrid manufacturing—that is, additive manufacturing (3D printing) combined with more precise machining and conventional subtractive machining—is among the most important developments in CNC machining. While CNC machining guarantees great accuracy and a superior surface polish, additive manufacturing lets one create elaborate, complex geometries, and complex components.

Combining these two techniques allows manufacturers to create extremely detailed vehicle components—which would otherwise be challenging or impossible to do with a single approach. This combined strategy lowers material waste, increases design flexibility, and raises general manufacturing efficiency.

Automation, Artificial Intelligence, and Robotics in CNC Machining

To increase manufacturing productivity and lower dependency on manual labor, CNC machining is progressively including robotics and automation. Faster turnaround times and reduced production costs follow from automated CNC machining services and systems running continuously with minimum human involvement.

Furthermore, influencing CNC machining capabilities by streamlining processes, predicting possible mistakes, and raising general quality control are artificial intelligence (AI) and machine learning. Real-time production data analysis enabled by AI-driven CNC systems can make changes to improve consistency and precision.

Sustainability and Eco-Friendly Manufacturing Practices

Environmental issues are getting more and more important, hence automakers are concentrating on making their CNC technology and machining more sustainable. Businesses are using energy-efficient CNC machines, besting material use to save waste, and including environmentally friendly machining fluids.

Moreover, developments in reusing and recycling CNC machining process scrap materials serve to lower the environmental impact of vehicle production. These initiatives fit the general industry trend toward green manufacturing technology and sustainability.

How CNC Machining Is Used in the Automotive Industry

From designing unique vehicle parts to building complex engine components, CNC machining finds application in many facets of automobile manufacture. Among the major, traditional machining uses are:

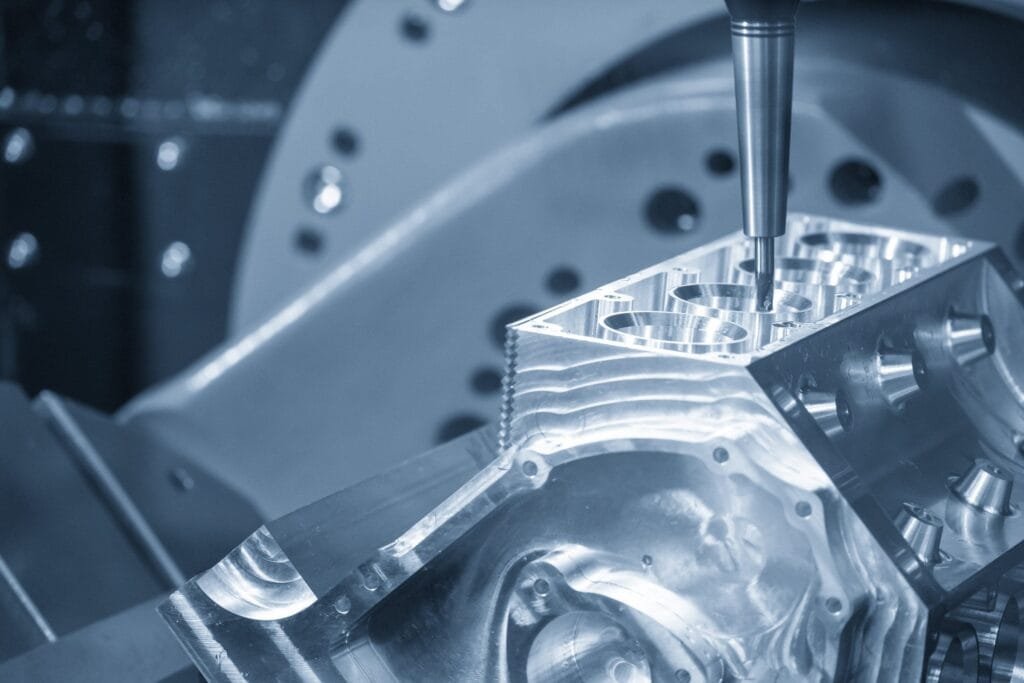

1. Engine Components

CNC machines create basic engine components including pistons, crankshafts, cylinder heads, and engine blocks. These parts must be quite exact to guarantee endurance under great pressure and smooth functioning.

2. Transmission Systems

Transmission systems depend on exactly machined gears and bearings. Tight tolerances made possible by CNC machining let producers create these complex parts, with perfect power transfer between the engine and the wheels.

3. Braking Systems

In vehicle engineering, safety comes first; CNC machining generates premium brake parts exhaust system components like master cylinders, rotors, and calipers. These components depend on accurate specifications to operate consistently and properly.

4. Suspension and Steering Components

Craftsmanship of suspension and steering components including control arms, tie rods, and steering knuckles depends critically on the accuracy of CNC machining. Strong and exact construction of these components guarantees vehicle stability and handling.

5. Prototyping and Customization

Prototyping for new car models is done by automotive designers and engineers using CNC machining. . Custom automotive parts and accessories lighting components including alloy wheels, spoilers, and personalized interior features are also produced using CNC machining by aficionados and specialty manufacturers.

Advantages of CNC Machining in Automotive Manufacturing

CNC machining’s application in the automobile sector offers various benefits:

1. High Precision and Accuracy

Tight tolerances produced by CNC machining guarantee that every component satisfies exact standards. This accuracy enhances dependability and performance of cars.

2. Efficiency and Speed

In the applications of CNC machining, automation lowers production time, therefore enabling businesses to take traditional manufacturing methods to rapidly and effectively produce large volumes of components without sacrificing quality automotive machining.

3. Reduced Waste and Cost Savings

Excess material waste is common outcome of conventional machining techniques. CNC machining maximizes material consumption, so lowering costs and improving environmental friendliness of the manufacturing process.

4. Consistency and Repeatability

Because CNC machining is computer-operated, every manufactured part is exact, guaranteeing manufacturing uniformity and lowering mistakes.

5. Versatility in Materials

Aluminum, steel, titanium, and even carbon fiber are among the materials CNC machining can work with internal combustion engine, so providing automotive companies design and manufacturing freedom.

Challenges of CNC Machining in the Automotive Industry

CNC machining has certain difficulties even with its benefits:

1. High Initial Investment

Setting up CNC machining facilities requires significant capital investment in equipment and skilled labor machining for the automotive. Still, long-term savings usually offset the starting expenses.

2. Complex Programming Requirements

CNC machining requires specialist understanding of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software machining for the automotive. Skilled operators are needed to program and manage production.

3. Maintenance and Downtime

CNC machines require regular maintenance to ensure precision and prevent breakdowns. Unplanned downtime can disrupt production schedules and increase costs.

The Future of CNC Machining in Automotive Manufacturing

As technology advances, CNC machining continues to evolve, shaping the future of automotive manufacturing. Among the developing trends are:

1. Integration with AI and Machine Learning

Artificial intelligence (AI) and machine learning are being implemented into CNC systems to improve productivity, detect problems, and optimize production.

2. Increased Use of 3D Printing with CNC Machining

Hybrid manufacturing, combining 3D printing and CNC machining, is gaining traction. This allows for quick prototyping with additive manufacturing followed by CNC finishing for precision.

3. Automation and Robotics

More automotive plants are merging robotic arms with CNC machines, significantly enhancing automation and lowering reliance on human labor.

4. Sustainable Manufacturing Practices

Manufacturers using sustainable materials and energy-efficient machining techniques help CNC machining develop to lower its environmental effect.

Conclusion

Automotive CNC machining has changed vehicle design and manufacture. From high-performance engine parts to customized accessories, CNC machining provides unmatched precision, efficiency, and reliability. While problems like high costs and complex programming continue, developments in technology are making CNC machining more accessible and efficient than ever. CNC machining will stay front and foremost in car manufacture as the automotive sector keeps innovating, therefore influencing the direction of mobility. CNC machining has become a vital technology in the automobile sector, enabling the creation of high-precision parts that enhance vehicle performance, safety, and efficiency. From lathe and milling machines to laser cutters and EDM systems, each type of CNC machine serves a unique purpose in manufacturing critical automotive components.

As technology continues to grow, hybrid production, automation, AI integration, and sustainable machining techniques are driving the future of CNC machining in the automobile sector. These developments will help manufacturers to create even more sophisticated car components with increased efficiency and minimum waste.